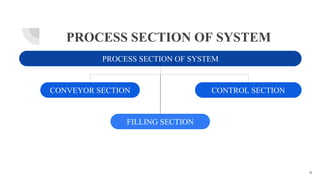

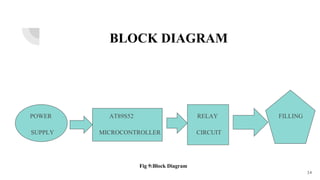

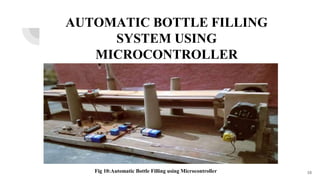

This document presents an automatic bottle filling system using a microcontroller. The system consists of a conveyor section to move bottles, a filling section with sensors, and a control section using a microcontroller. As bottles pass on the conveyor, IR sensors count them and stop them for filling. A DC water pump then fills each bottle to a user-defined volume before the conveyor moves it along. The microcontroller controls the sensors, pump, and conveyor motor to automate the filling process. The system aims to reduce human effort in filling bottles while allowing customizable fill levels through a simple control interface.

![REFERENCE

[1]Arthur Pius Santiago [2010]:Insecticide Bottle Filling and Capping machines in De La

Salle University .

[2]S.M Khalid Reza,Shah Ahsanuzzaman Md.Tariq,S.M Mohsin

Reza[2010]:Microcontroller Based Automated Water Level Sensing and Controlling.

[3] A.Jagadeesan, Sivaram,R.Cibi. S[2011]:Automated, Optimized And Secured Public

Distribution System Using Embedded Systems .International Journal Of Current Scientific

Research.

[4] T.Kalaiselvi1, R.Praveena2, Aakanksha.R3, Dhanya.S4[2012]: PLC Based Automatic

Bottle Filling and Capping System With User Defined Volume Selection.

20](https://image.slidesharecdn.com/automaticbottlefillingsystemusingmicrocontroller-190419135019/85/Automatic-bottle-filling-system-using-microcontroller-20-320.jpg)