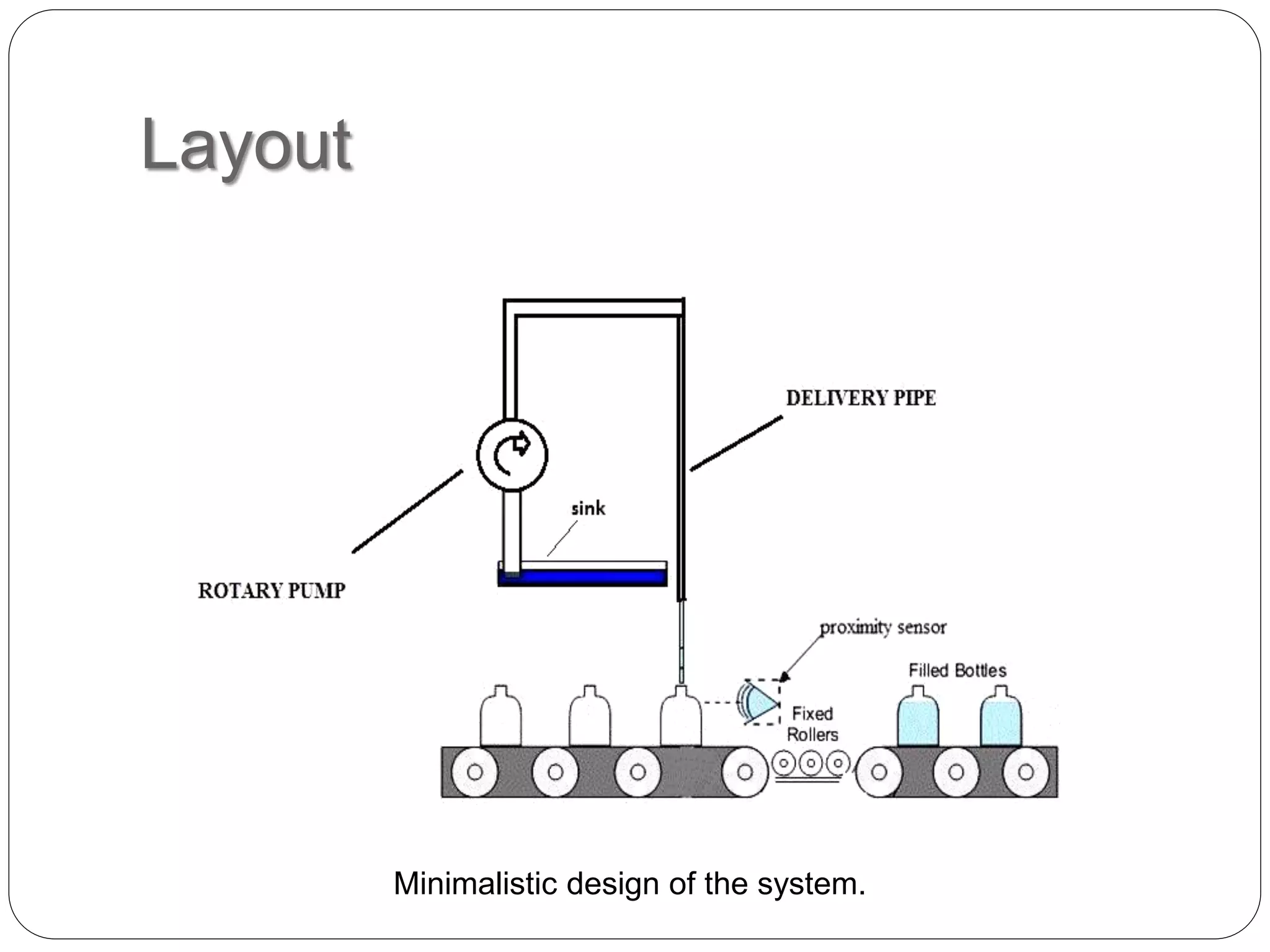

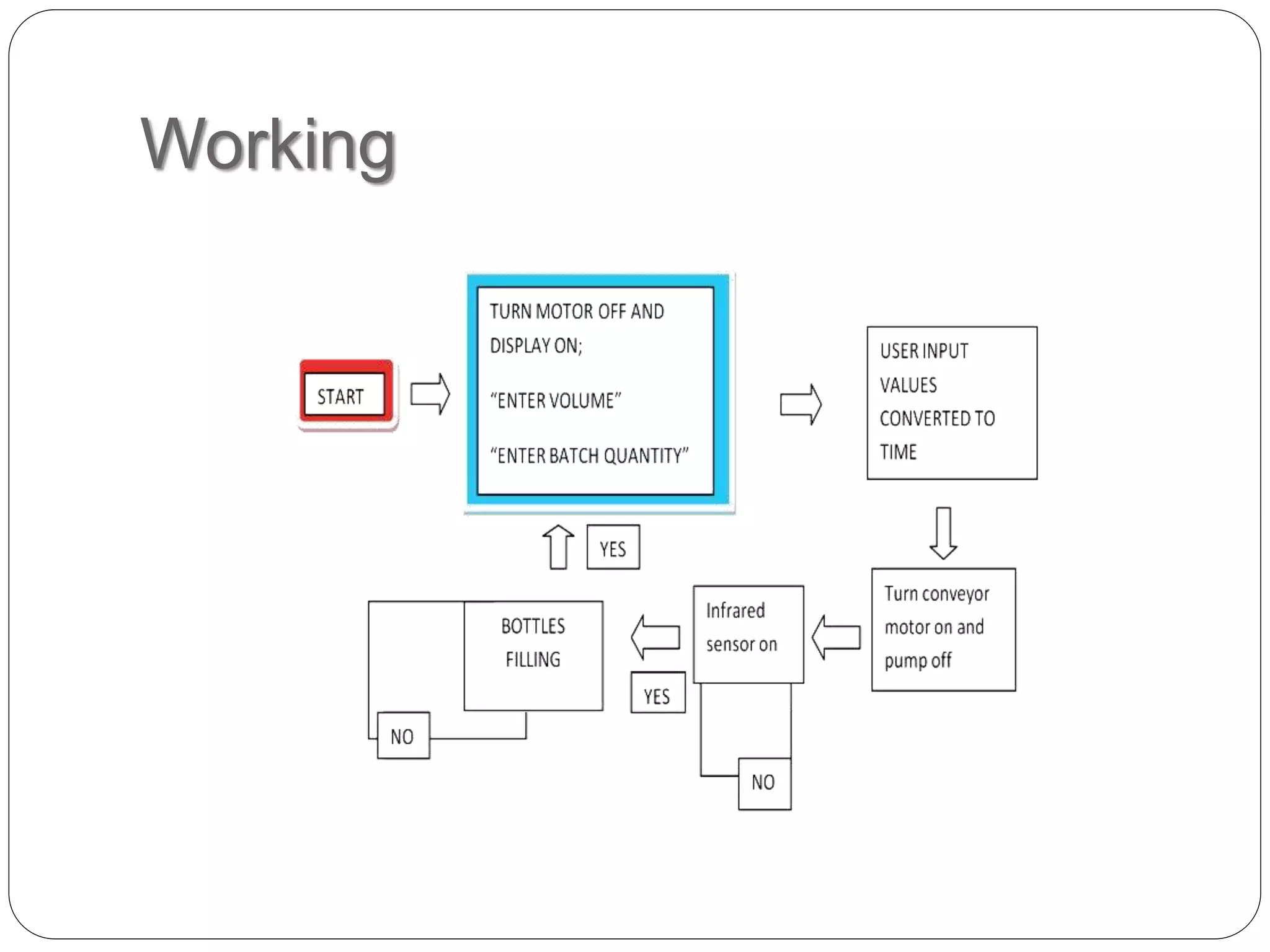

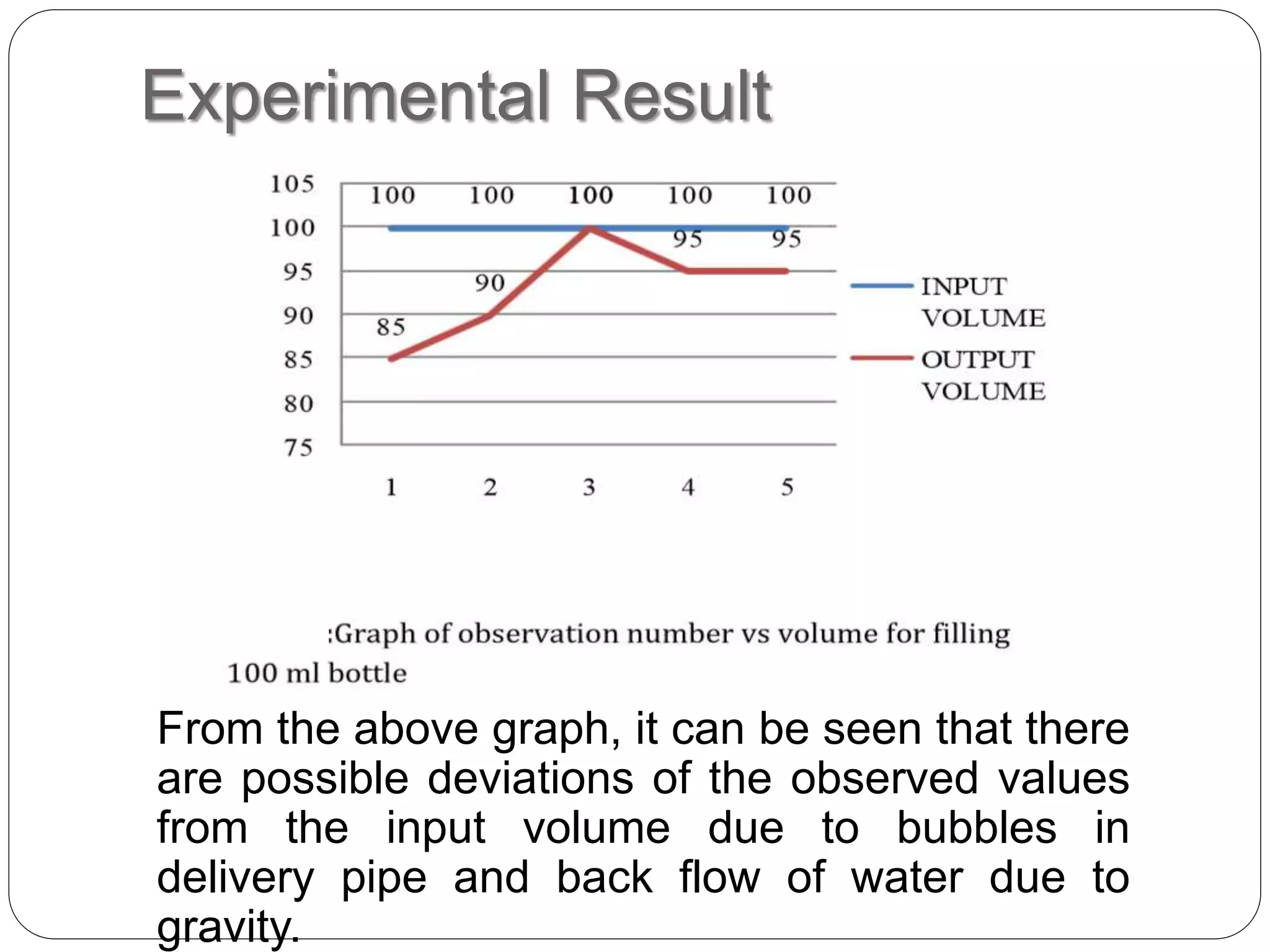

The document discusses the development of an automated bottle filling system using an Arduino microcontroller aimed at small industries to reduce the costs associated with manual filling. It outlines the system's components, design, working mechanism, and experimental results, emphasizing benefits such as increased productivity and reduced labor costs. The conclusion indicates that while the system is effective, it is best suited for situations where high precision and speed are not critical.