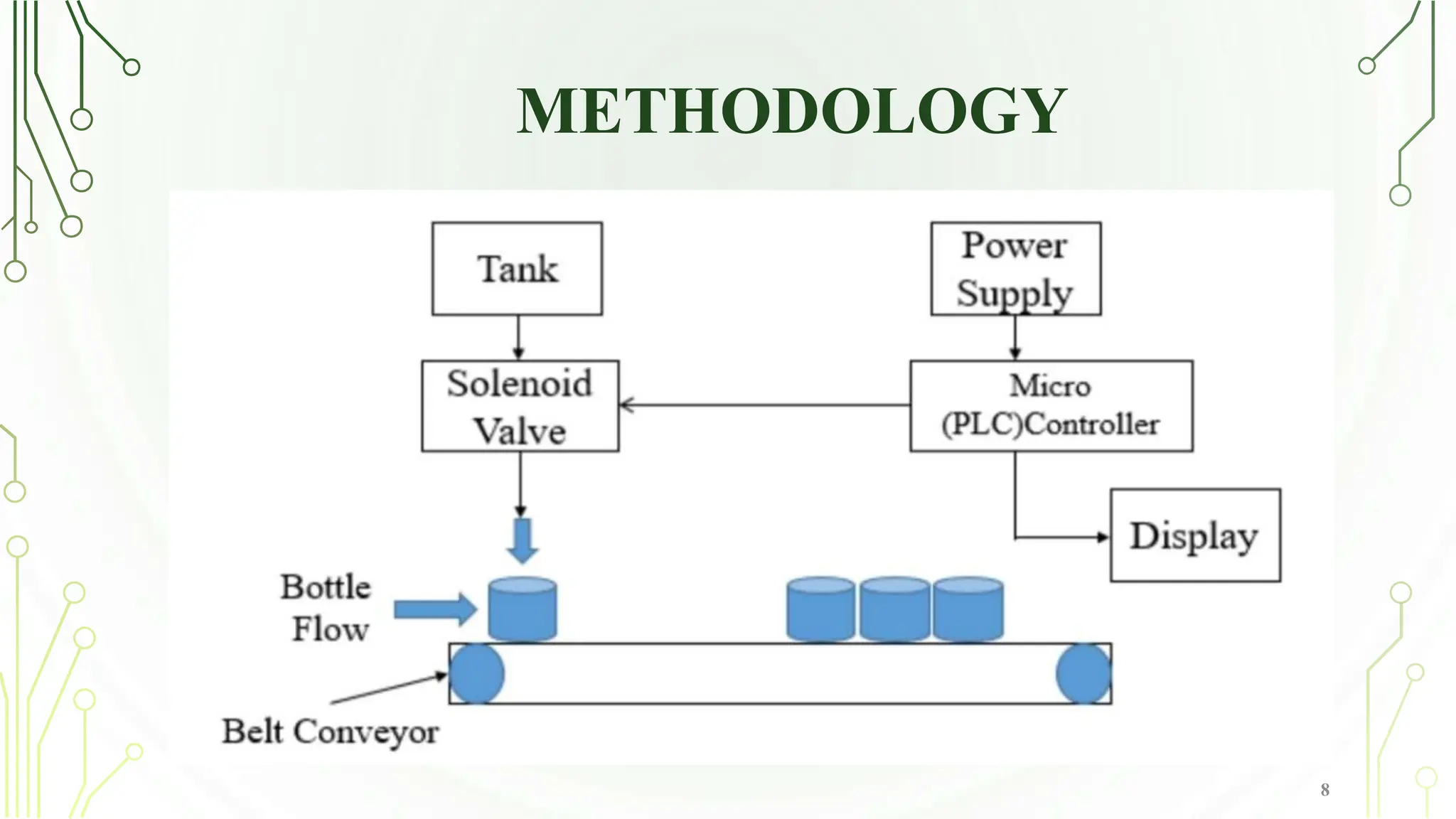

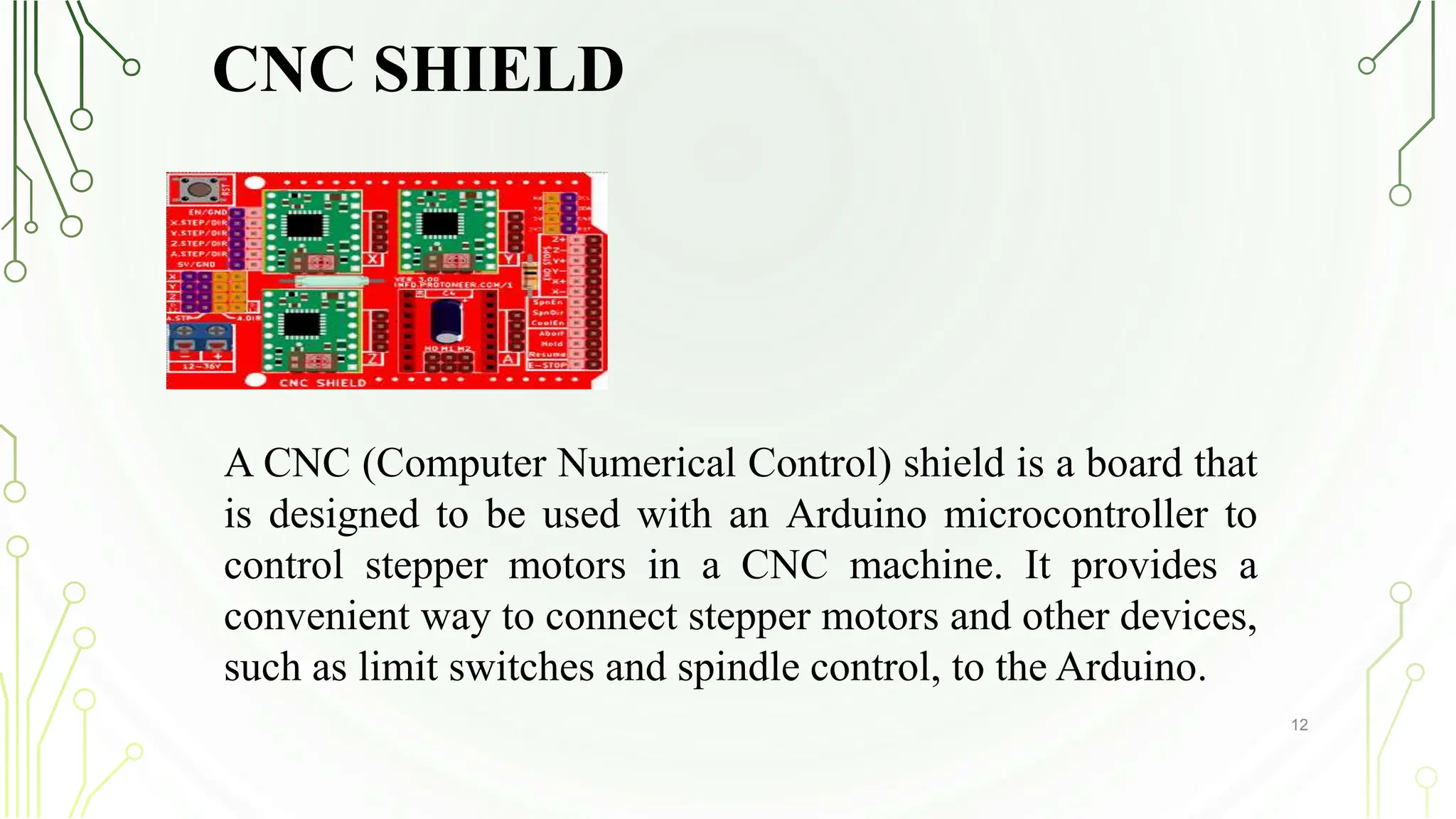

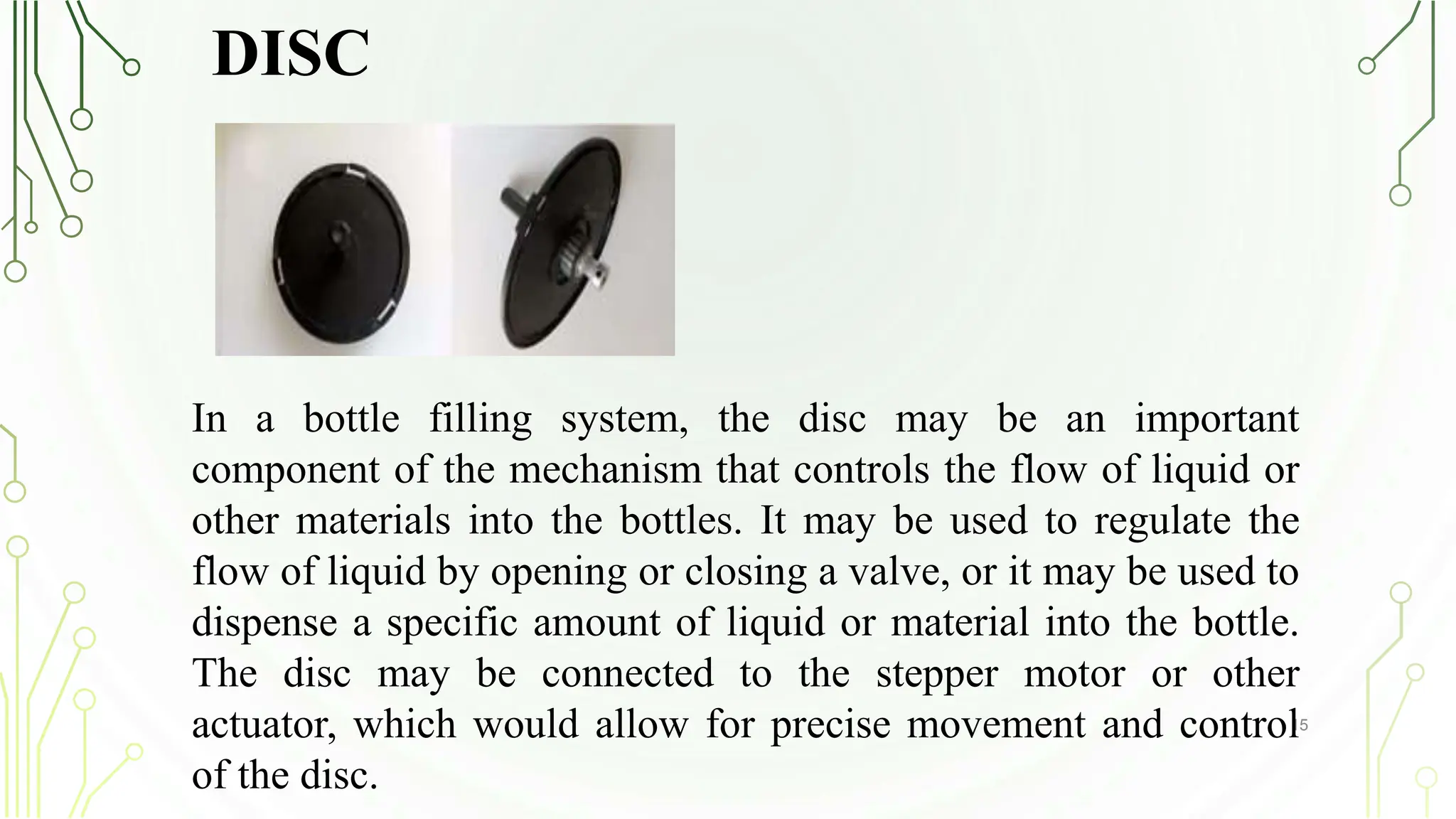

This document describes a student project to design an automatic bottle filling machine. It includes an introduction explaining bottle filling systems and objectives of consistent and accurate filling. The methodology uses an Arduino, sensors, stepper motor and other components. The outcomes are increased efficiency and production rates while reducing errors. It provides details on the components, advantages of automation, potential disadvantages and applications in various industries.