1. An autoclave is a device that sterilizes equipment and supplies by subjecting them to high pressure steam at 121°C for 15-20 minutes.

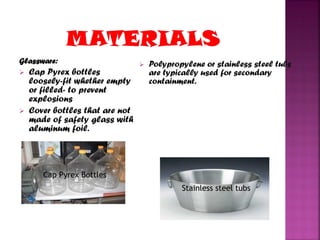

2. When autoclaving glassware, cap Pyrex bottles loosely and cover non-safety glass bottles with aluminum foil to prevent explosions.

3. Proper autoclave use involves following safety procedures like wearing protective equipment, waiting for full pressure release before opening, and allowing time for contents to cool before removal.