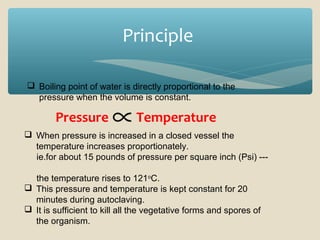

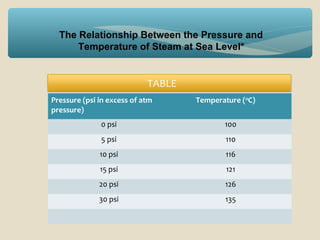

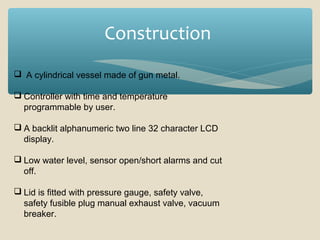

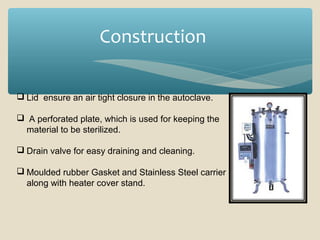

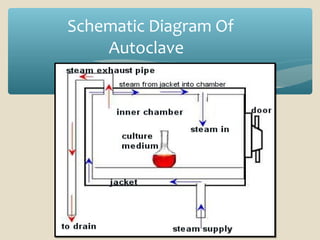

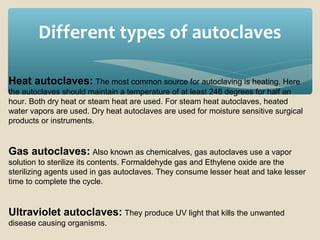

The document discusses the history and working of autoclaves. Autoclaves were invented in 1879 by Charles Chamberland to sterilize equipment using pressurized steam above the boiling point of water. Autoclaves work by increasing the pressure inside a sealed chamber, raising the temperature above 100°C to sterilize materials through wet heat. They have various applications in microbiology, medicine, dentistry and laboratories. Safety, cost, and ability to sterilize different materials pose limitations to their use.