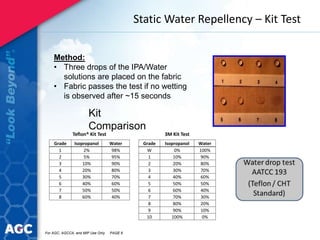

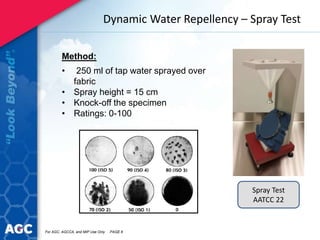

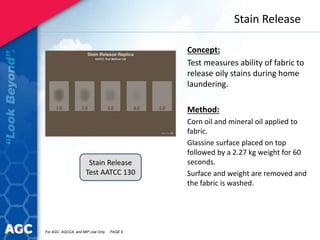

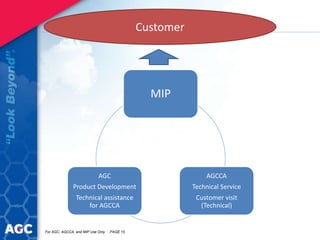

The document outlines technical support capabilities for textiles/nonwovens specific to AGC, AGCCA, and MIP, detailing functions such as fabric information, application services, and performance evaluation. It includes various testing methods for water and oil repellency, stain release, wash durability, hydrostatic pressure, static decay, and surface resistivity, each with specified procedures and parameters. Direct customer support is available in the USA, Mexico, Canada, and South America, with contact information provided for further inquiries.