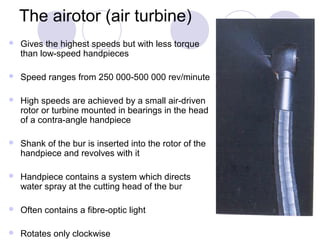

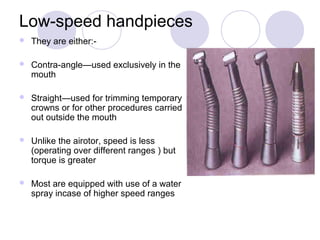

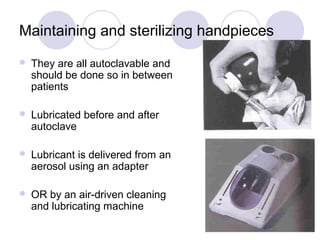

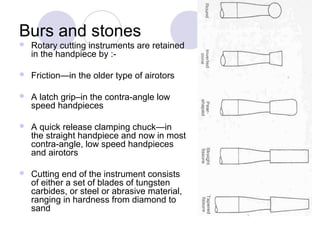

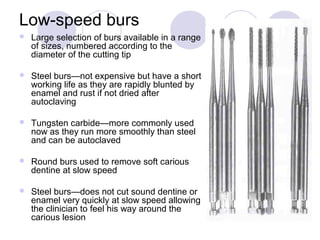

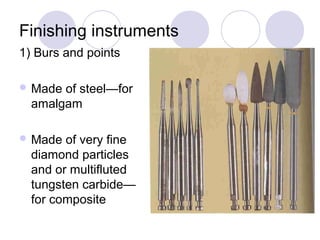

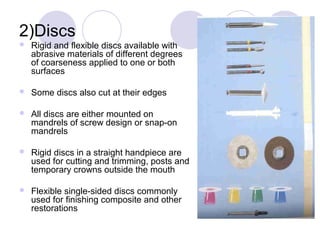

This document discusses rotary instruments used in dentistry, including their types, functions, and proper use and maintenance. It describes air-driven high-speed handpieces and lower-speed electric handpieces, along with the burs, stones, discs and other attachments used with each. Precautions for minimizing heat, pressure and trauma to patients during procedures are also outlined.