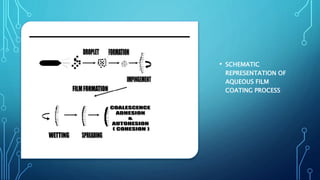

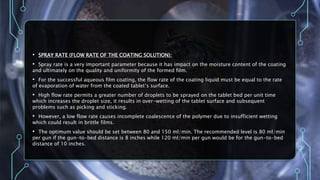

The document discusses the aqueous film coating process in pharmaceutical tablet manufacturing, presenting an overview of tablet coating types: sugar, film, and enteric coatings, with a focus on the film coating methodology. It outlines the objectives, advantages, and critical process parameters such as spray rate, gun position, air pattern, pan speed, and temperature control, essential for ensuring quality in the end product. The document concludes with comparisons between film and sugar coatings, emphasizing the efficiency and minimal weight increase of film coating.