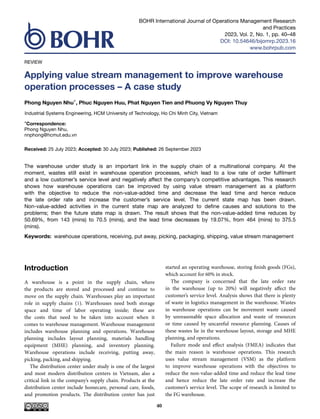

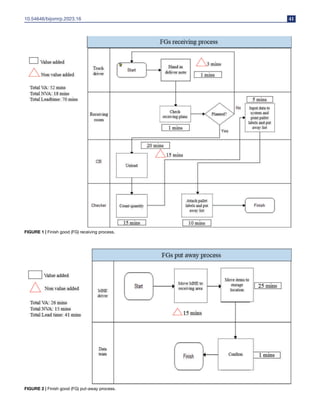

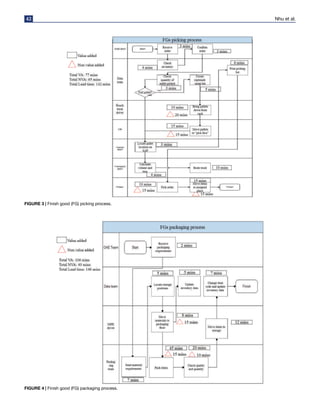

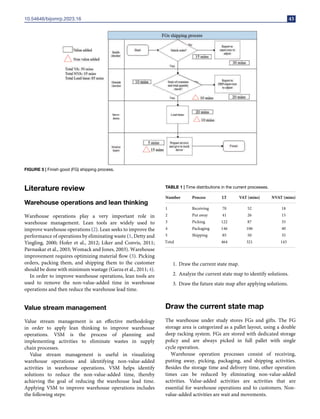

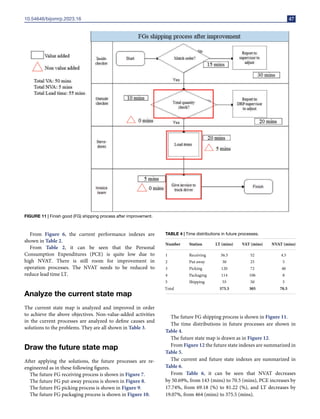

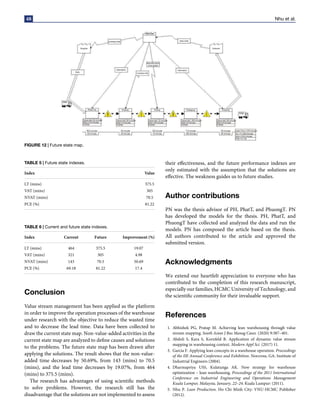

This study discusses the application of value stream management (VSM) to enhance warehouse operations at a multinational company's distribution center, focusing on reducing non-value-added time and lead time. The research indicates a 50.69% reduction in non-value-added time and a 19.07% decrease in lead time after implementing VSM. The findings suggest significant improvements in order fulfillment and customer service levels, although the study notes that the effectiveness of the proposed solutions has not yet been tested.