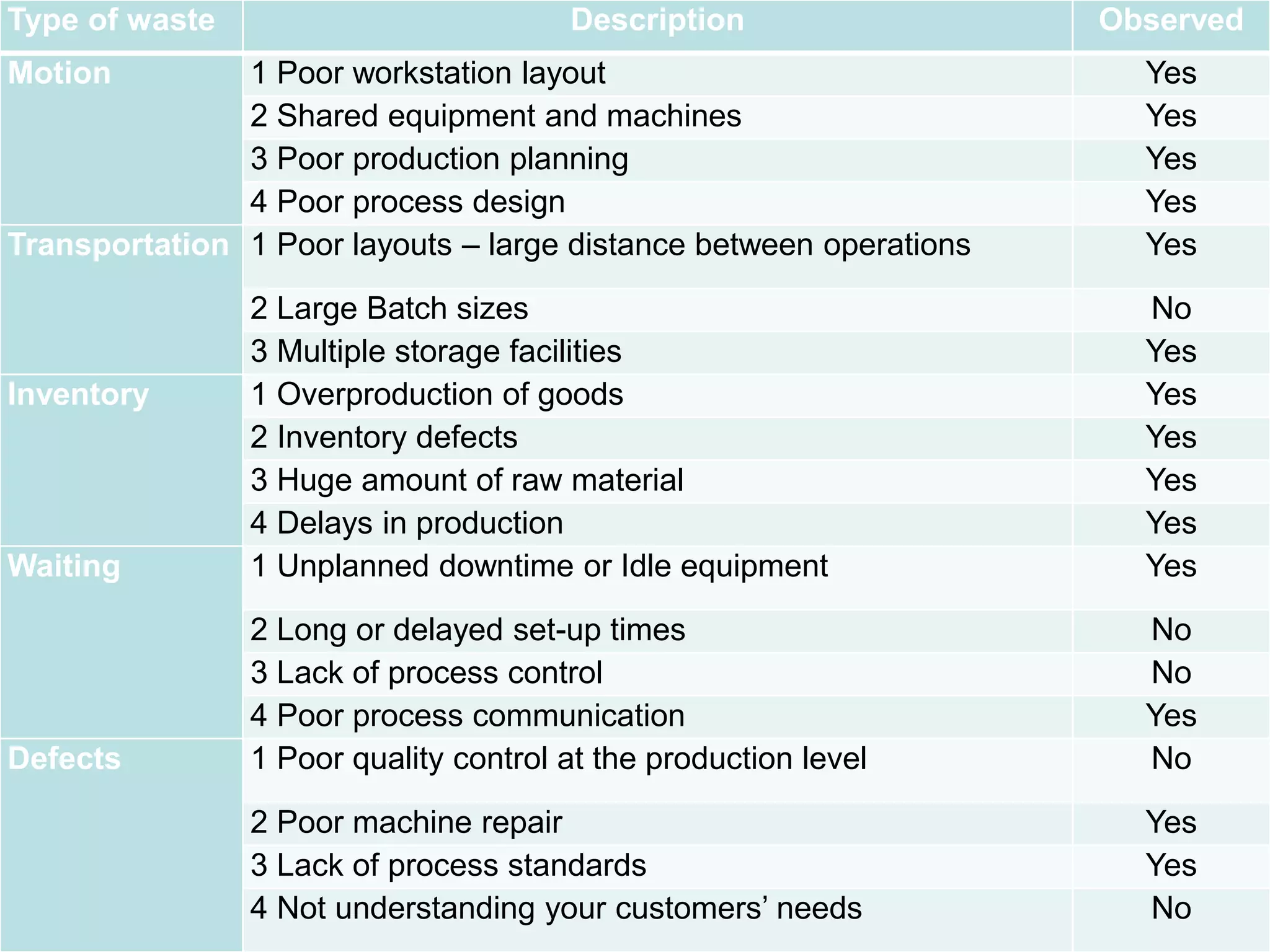

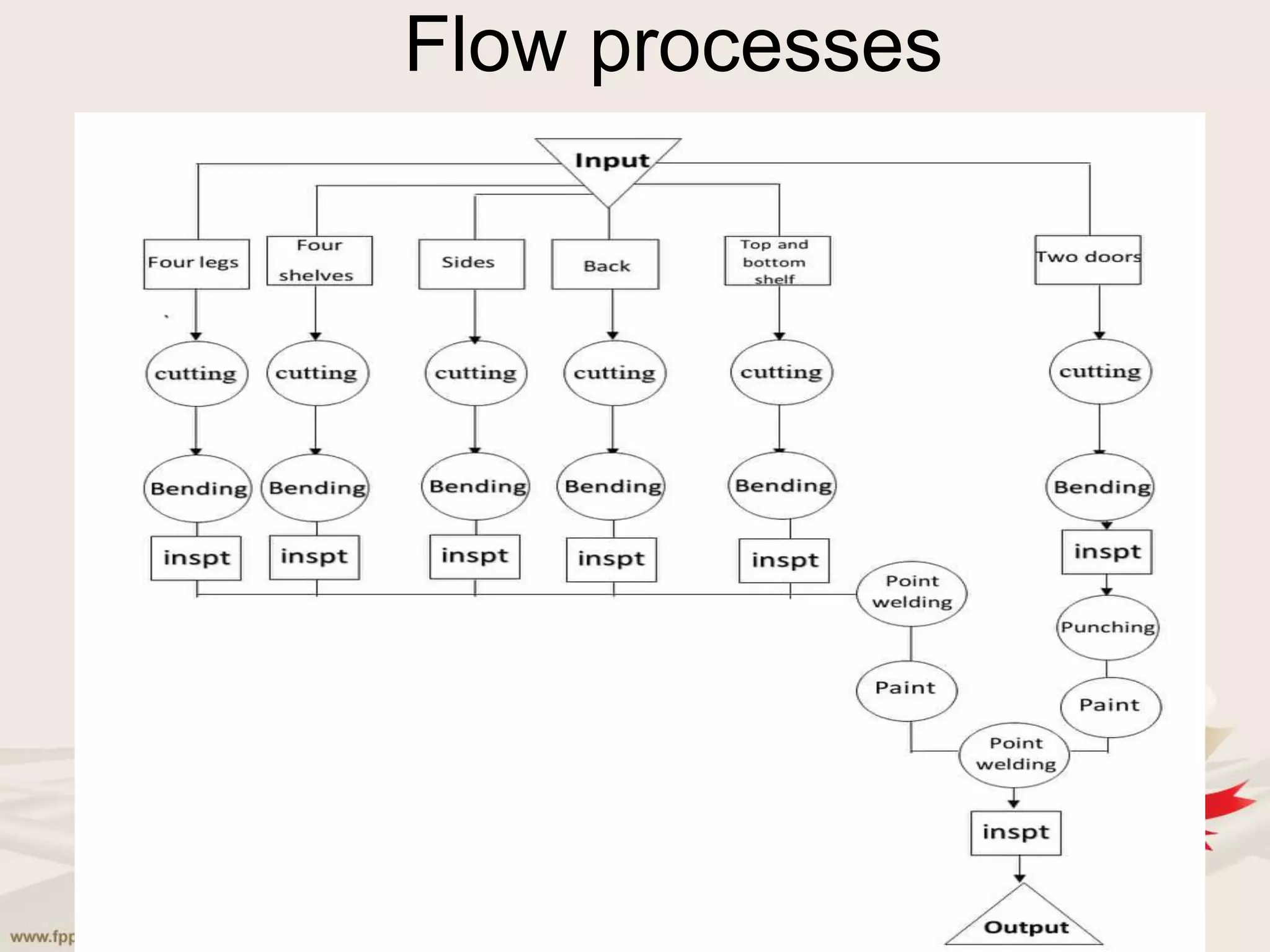

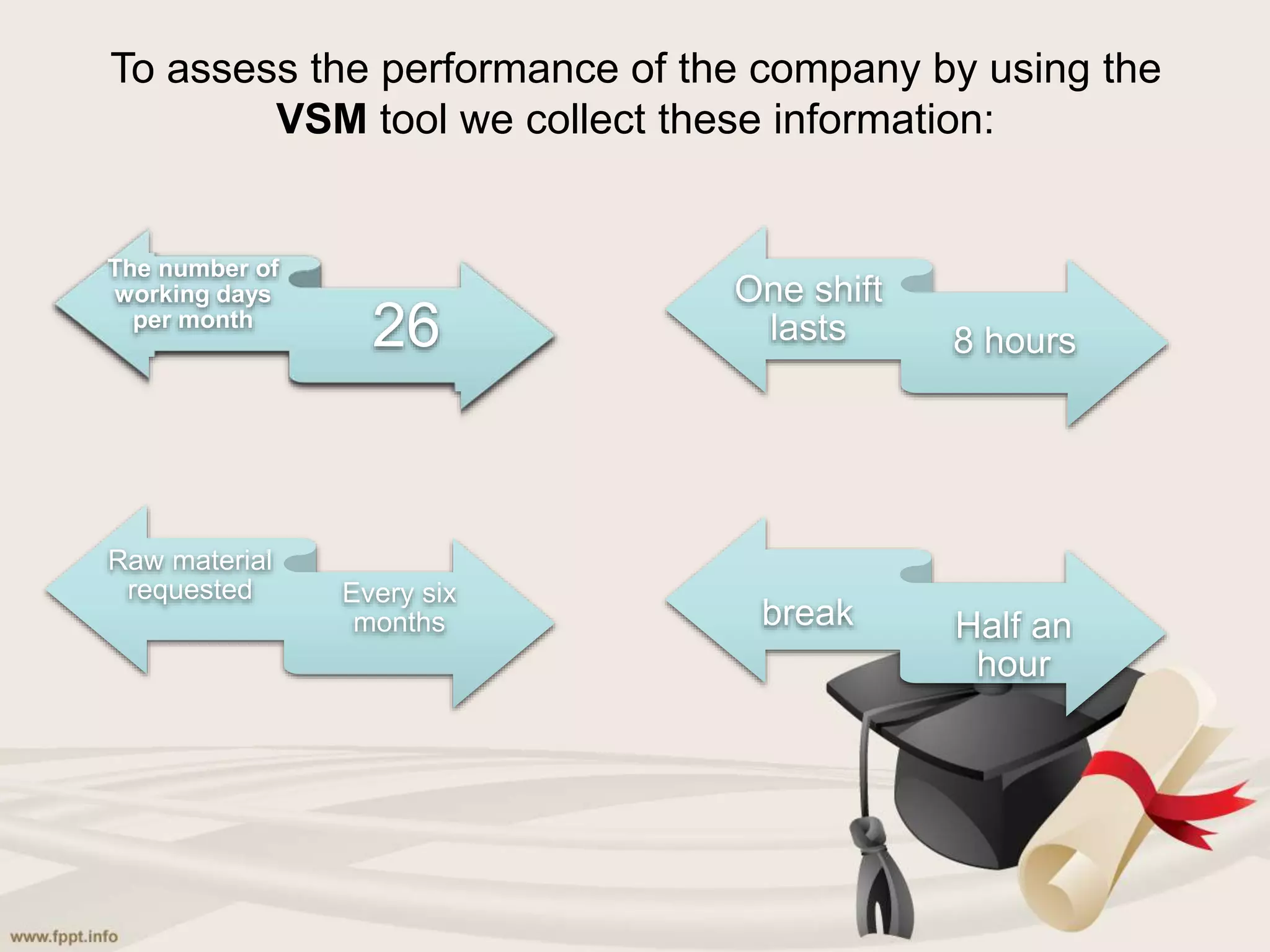

This document summarizes a case study applying lean manufacturing techniques at a furniture factory in Jordan. The researchers used various lean tools to analyze sources of waste, including a current state value stream map of a two-door cabinet production process. They identified issues like long lead times, low value-add percentage, and bottlenecks. A future state map was proposed with recommendations to achieve continuous flow, balance processes, and continuously improve through techniques like 5S and kaizen. Suggestions included better production planning, utilizing CNC machines, and improving marketing.