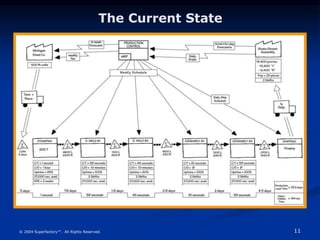

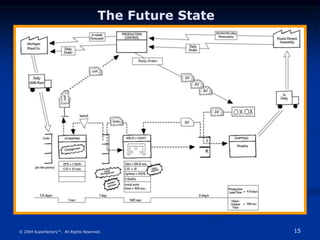

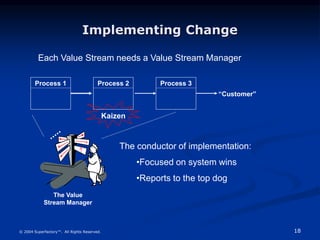

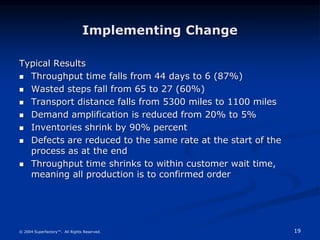

This document discusses value stream mapping and analysis. It defines a value stream as all actions required to deliver a product or service to a customer. It describes identifying and mapping current and future states, which typically show 80-90% of current steps as waste. Implementing change requires management commitment, empowered value stream managers, and kaizen teams to drive improvements like reduced lead times, inventories, and defects. Roadblocks can include habits, metrics, and lack of system thinking.