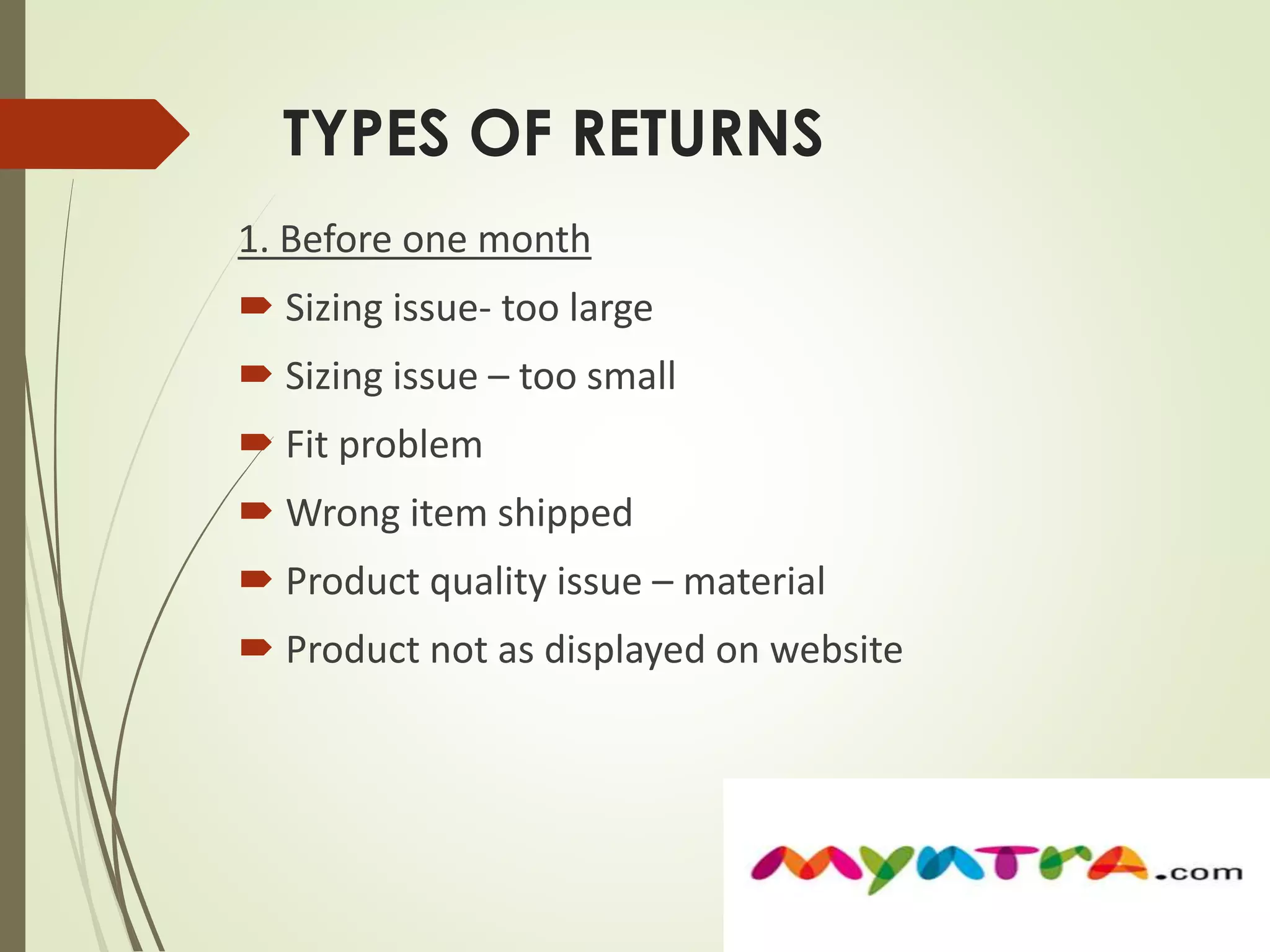

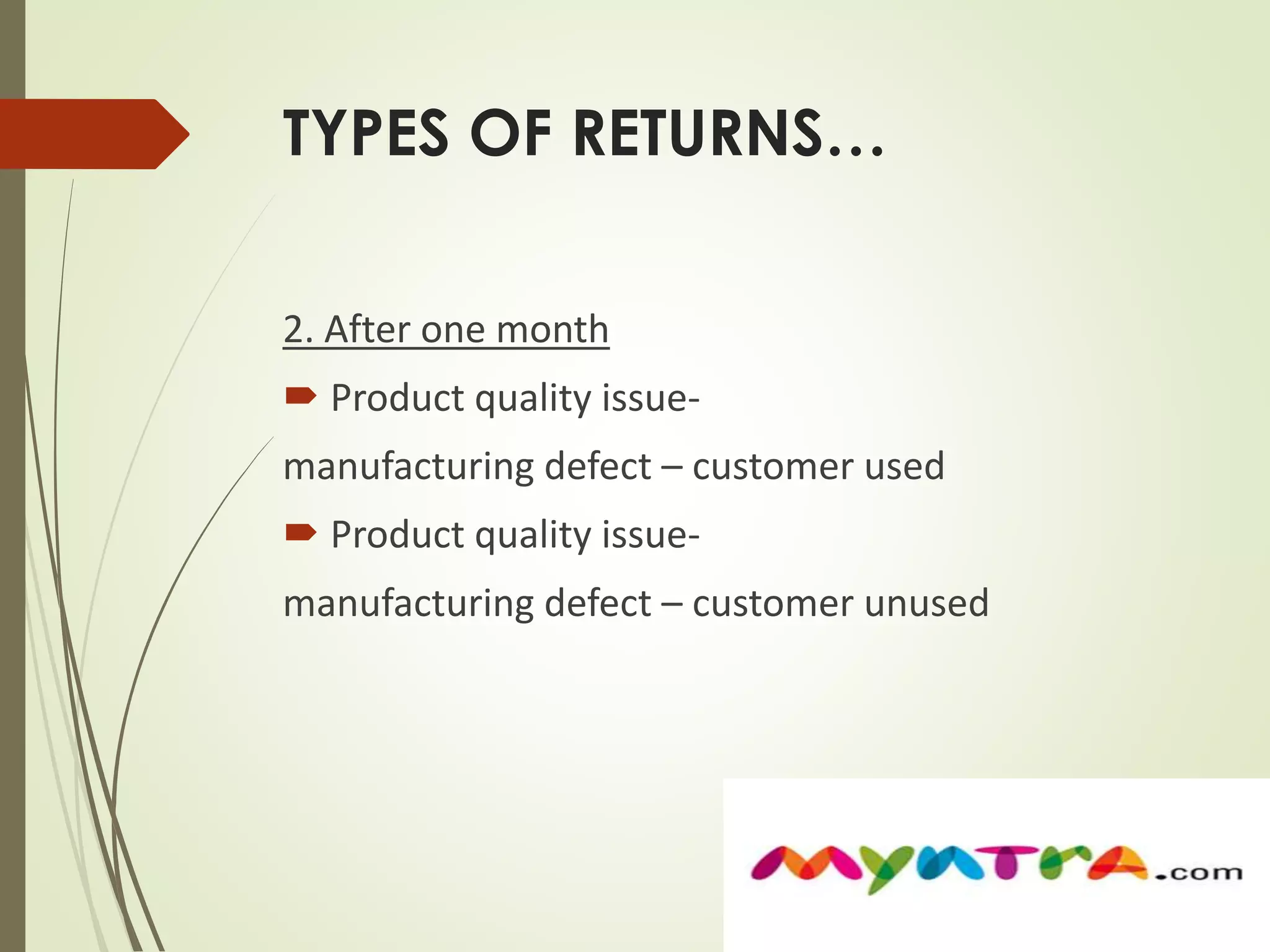

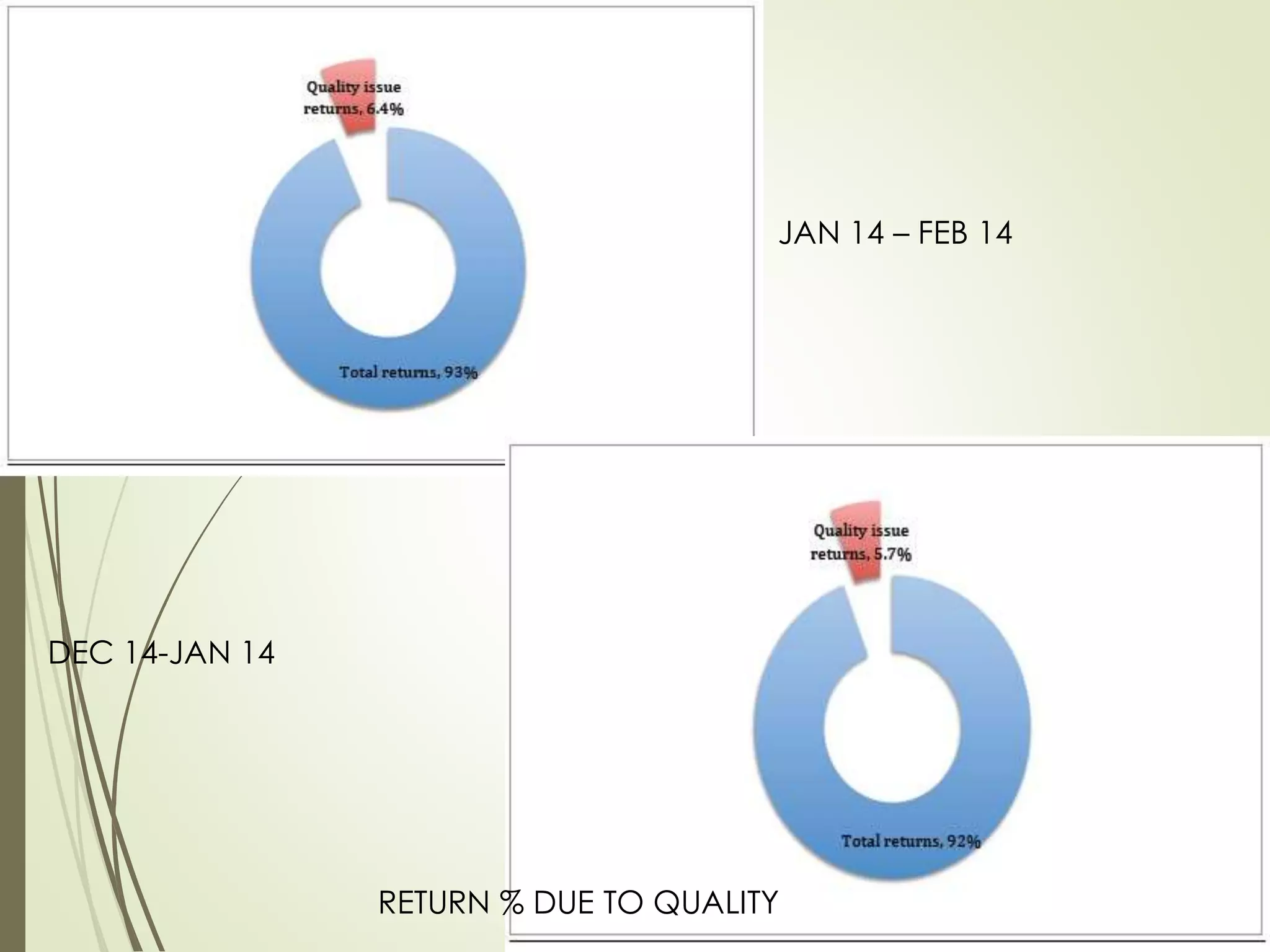

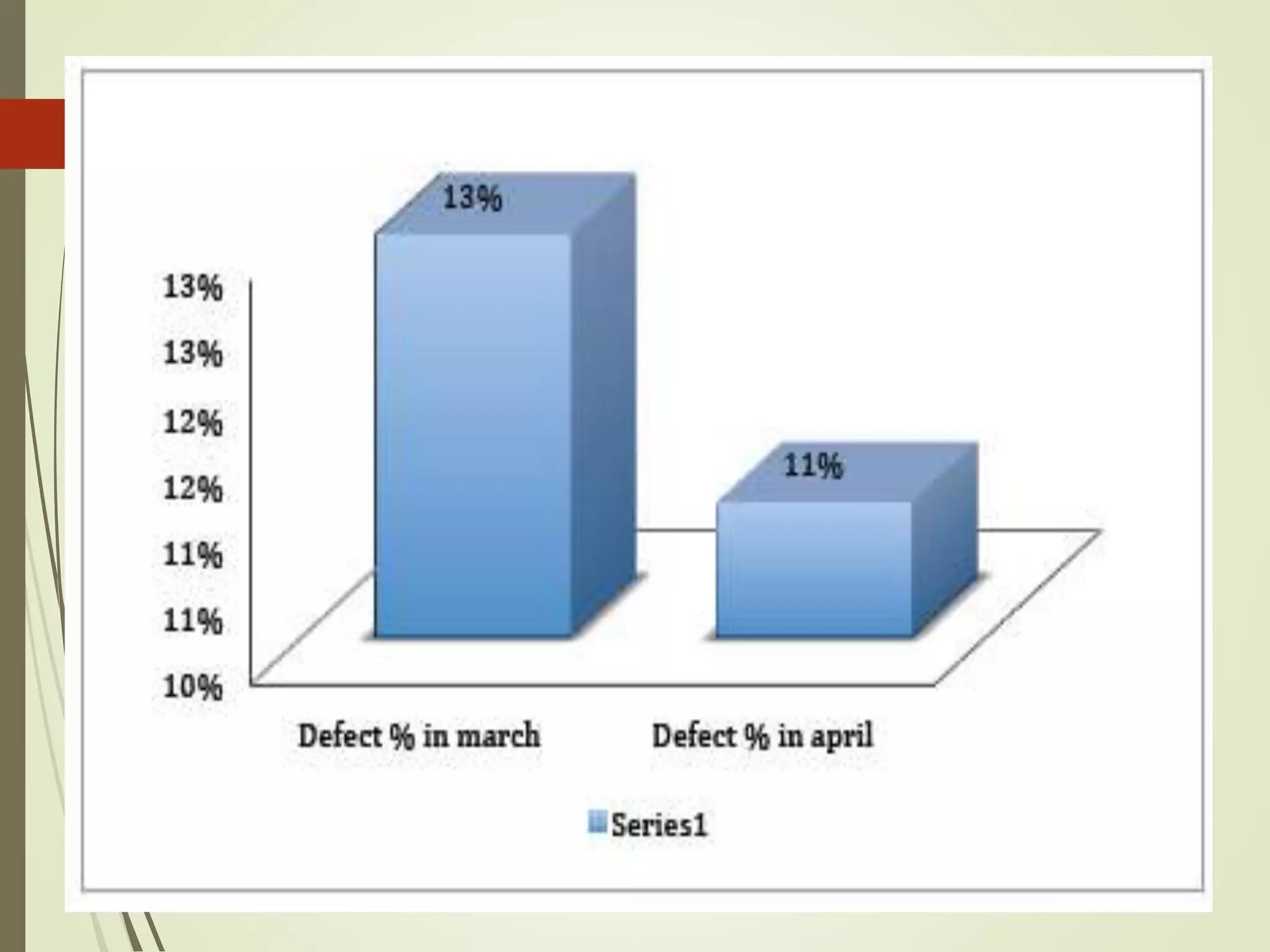

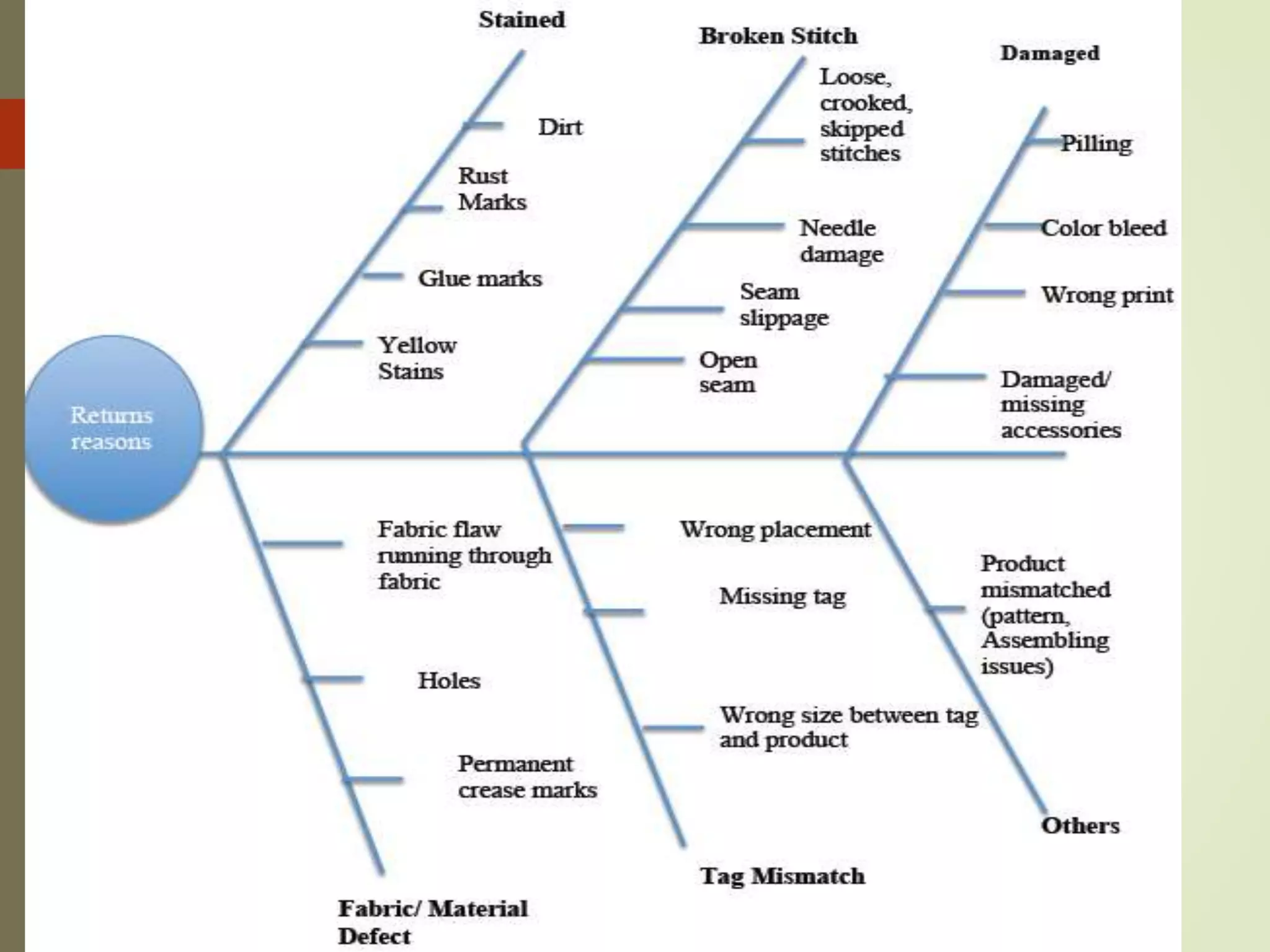

This document summarizes a student project analyzing quality issues and returns at the online clothing retailer Myntra. The students interviewed Myntra employees and analyzed return data from January to February 2014. They found that 6% of monthly returns were due to quality issues like manufacturing defects. To address this, the students developed a quality manual outlining Myntra's inspection and approval processes to help reduce returns and improve product quality.