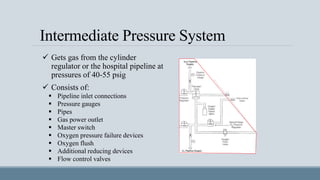

The document discusses the components and functions of an anesthesia machine. An anesthesia machine provides medical gases like oxygen and nitrous oxide mixed with anesthetic vapors to patients. It has several key components including pressure regulators, vaporizers, reservoirs, carbon dioxide absorbers, adjustable pressure limiting valves, ventilators, and scavenging systems. The machine precisely delivers gas mixtures to maintain anesthesia and ventilation. It is designed with three pressure systems - high, intermediate, and low - to safely regulate gas delivery.

![Carbon dioxide Absorber

Sodalime (CaOH2 + NaOH + KOH + silica) or Baralyme

(Ba[OH] 2 + Ca[OH]2) contained in the absorber combines

with carbon dioxide, forming CaCO2 and liberating heat and

moisture (H2O).

The canister should be changed when 25% to 50% of the

contents has changed color.

Soda lime is the most common absorbent and is capable of

absorbing up to 23L of CO2 per 100g of absorbent. It´s

main component is calcium hydroxide (80%).](https://image.slidesharecdn.com/anesthesiamachine-230321145755-70e3d283/85/anesthesia-machine-pptx-14-320.jpg)