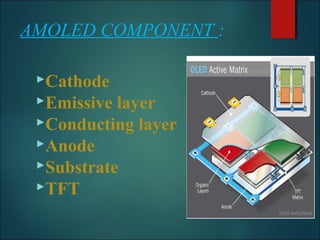

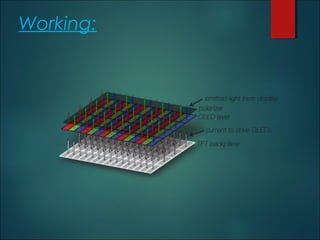

AMOLED (Active-Matrix Organic Light-Emitting Diode) is a display technology that offers efficient power consumption and faster refresh rates, making it suitable for applications like TVs and monitors. The technology relies on a matrix of OLED pixels and a thin film transistor array to control light emission and image quality. Future prospects include curved, transparent, and wearable AMOLED displays, along with potential challenges such as material degradation and limited lifespan.