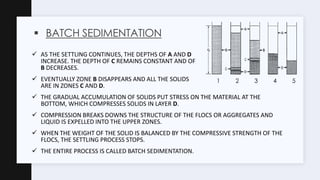

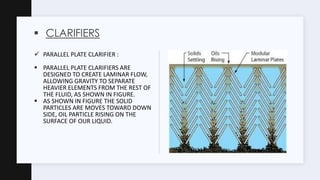

This document provides an overview of sedimentation as a process for separating solids from liquids by gravity settling. It defines sedimentation and describes types such as plain sedimentation and sedimentation with coagulation. Batch sedimentation is explained through different settling zones. Rate of sedimentation and applications are discussed. Common equipment for batch sedimentation include thickeners and clarifiers. Thickeners are used to concentrate solids while clarifiers purify liquids. Circular and parallel plate clarifiers are described.