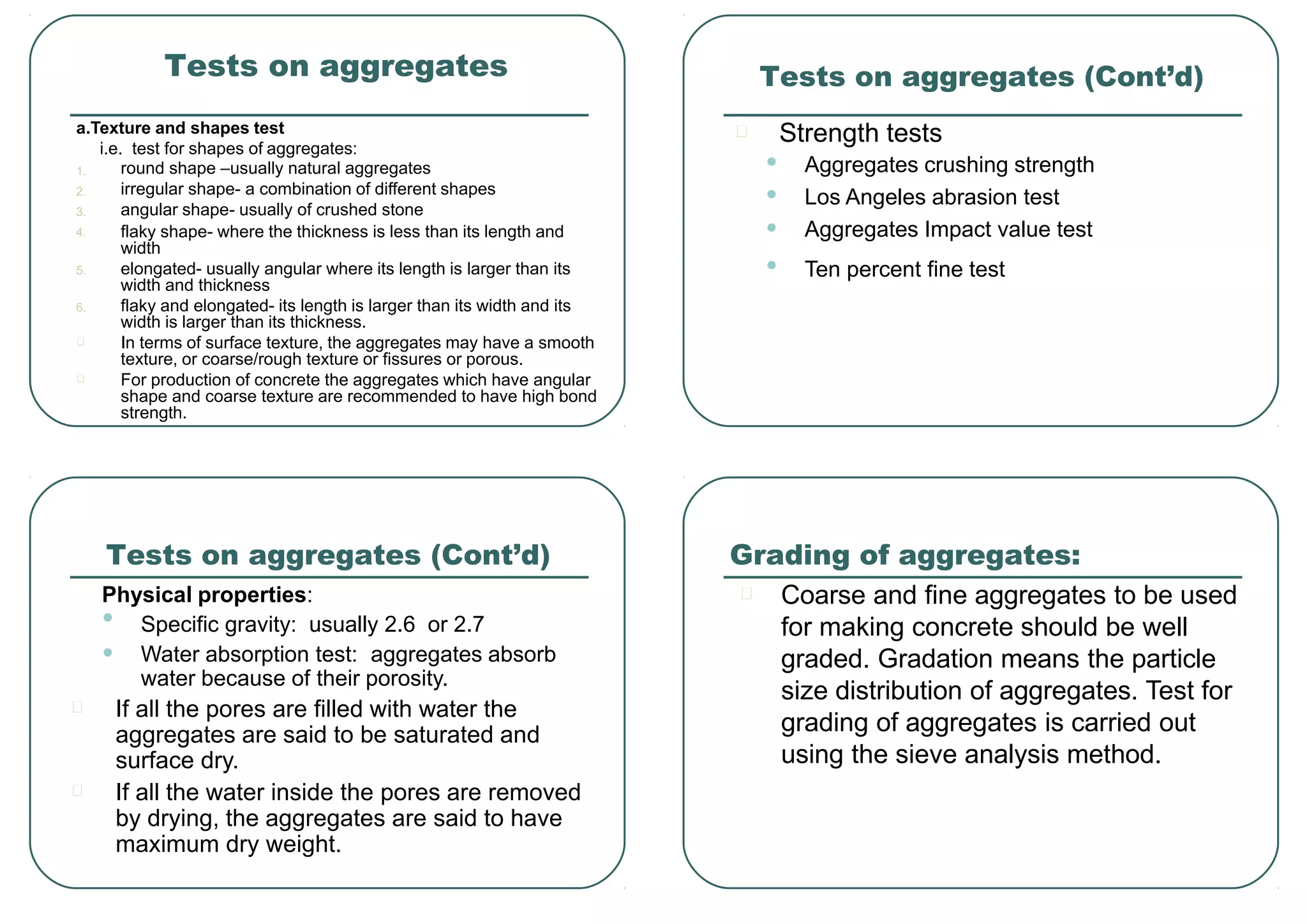

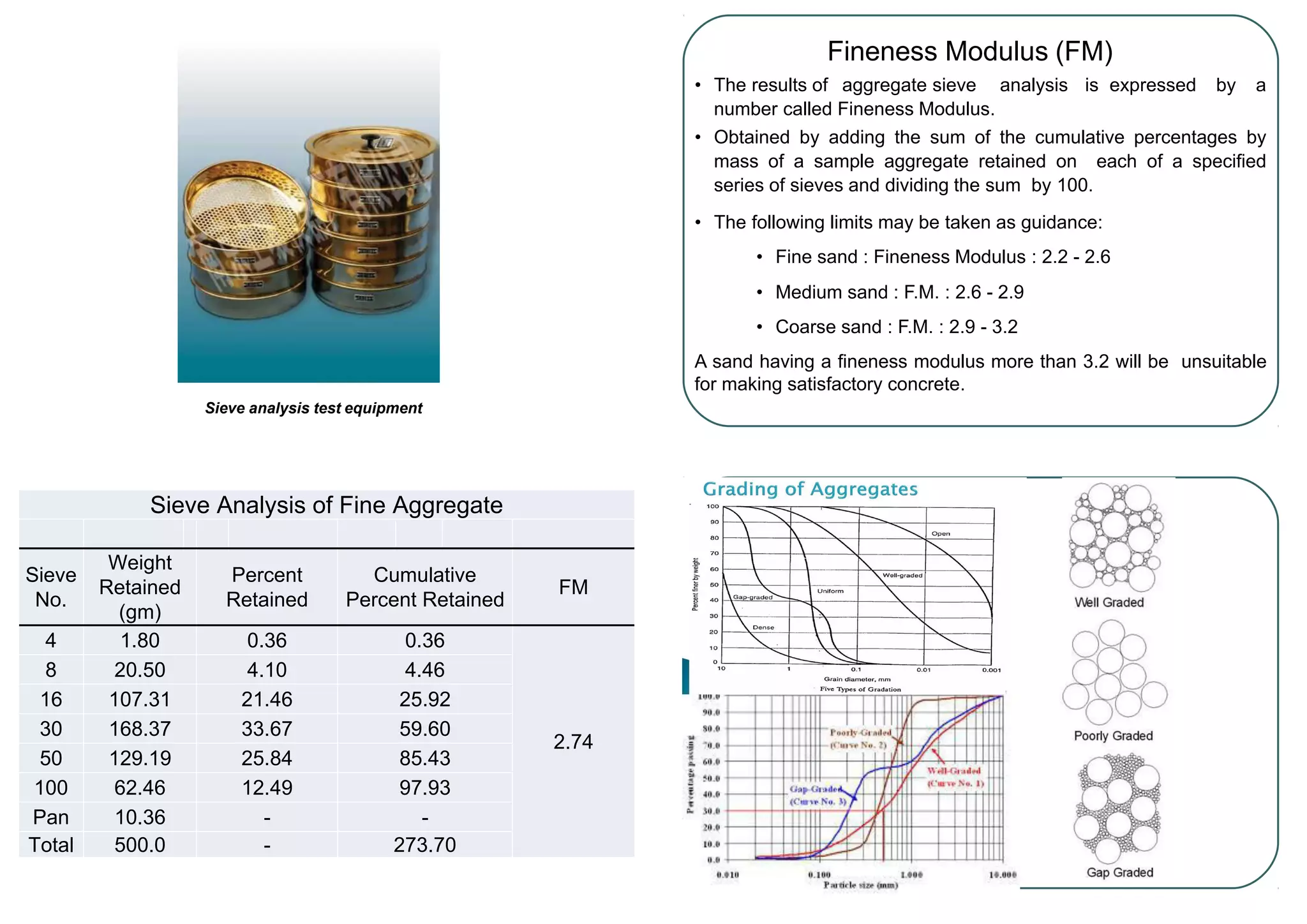

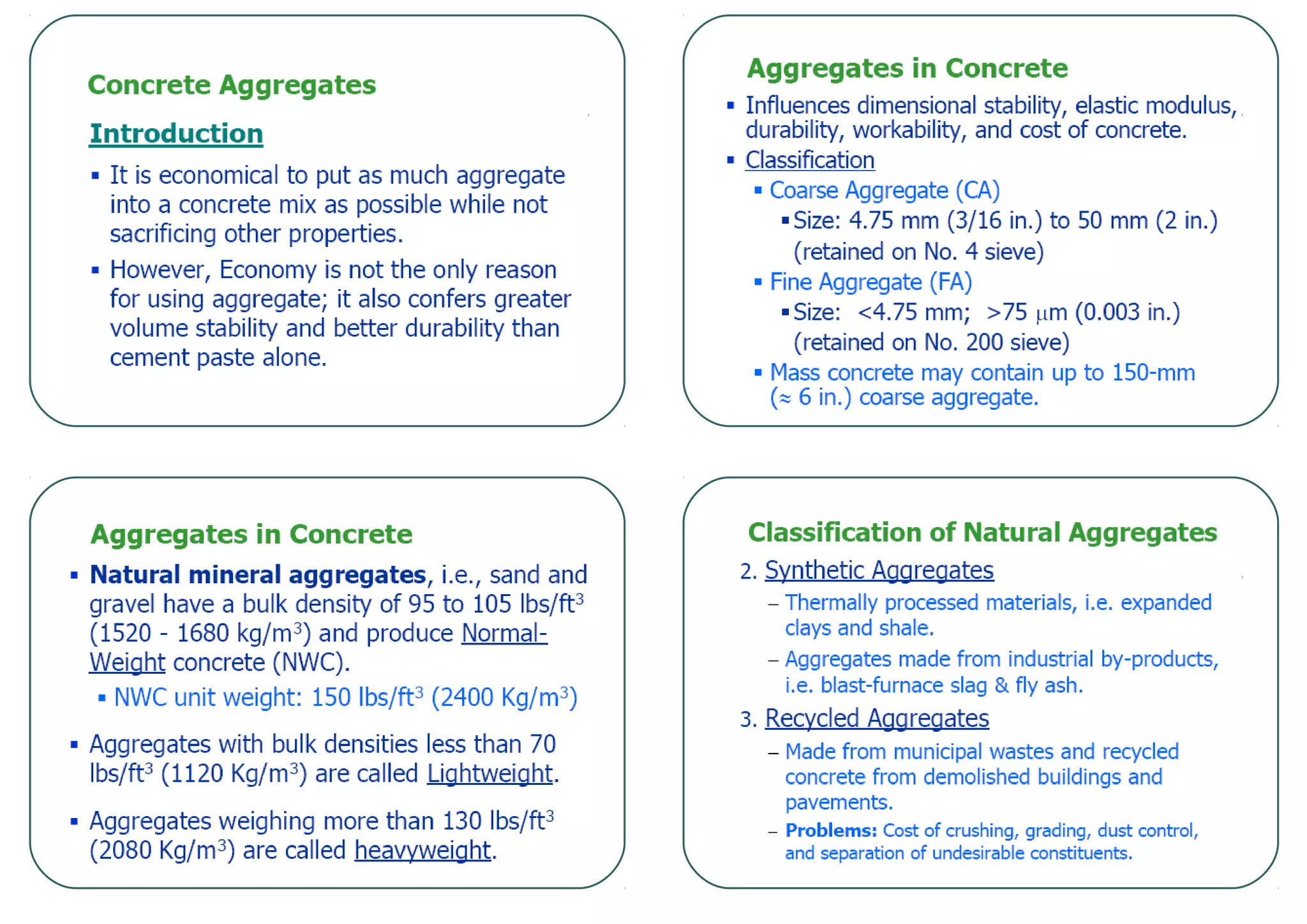

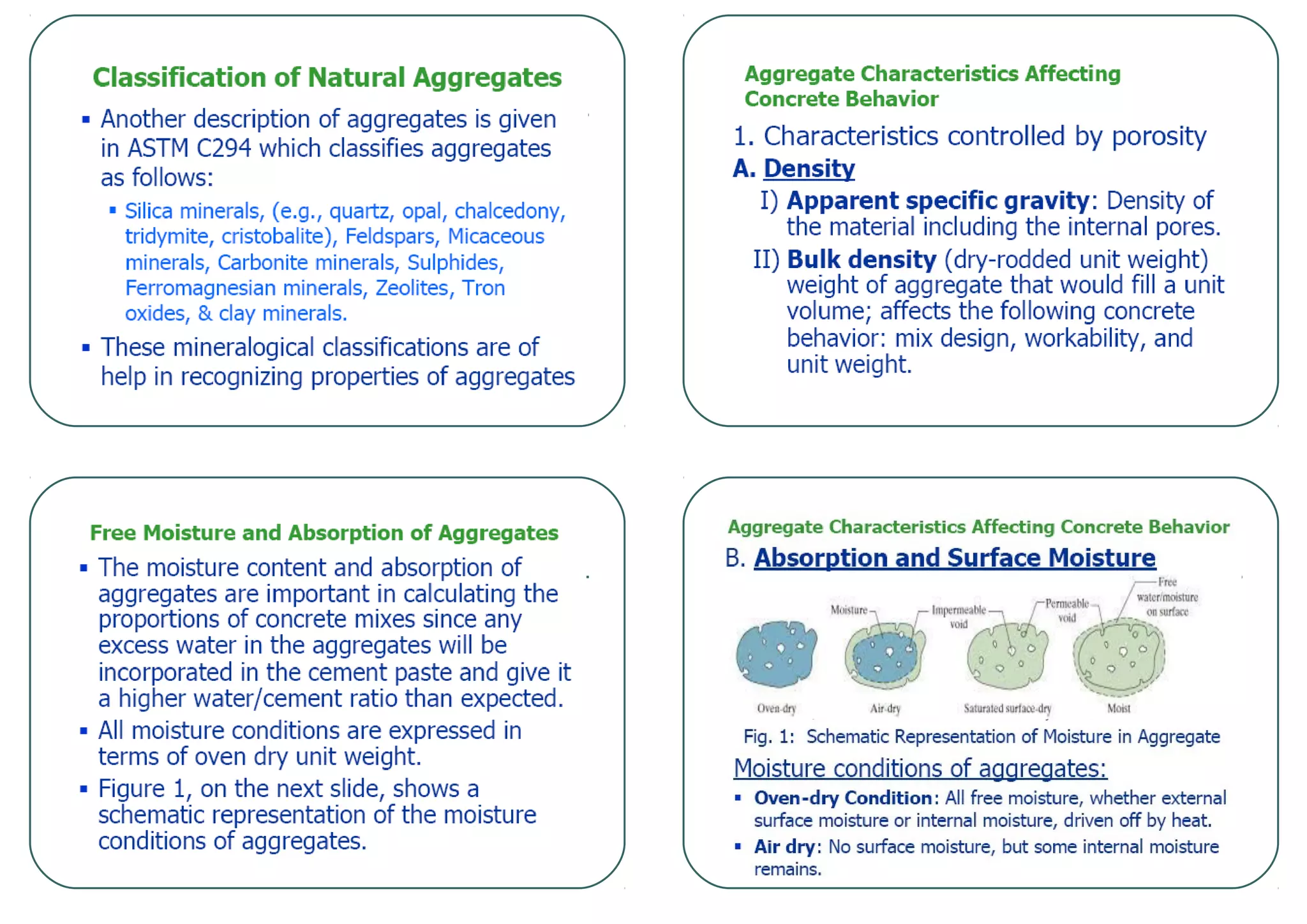

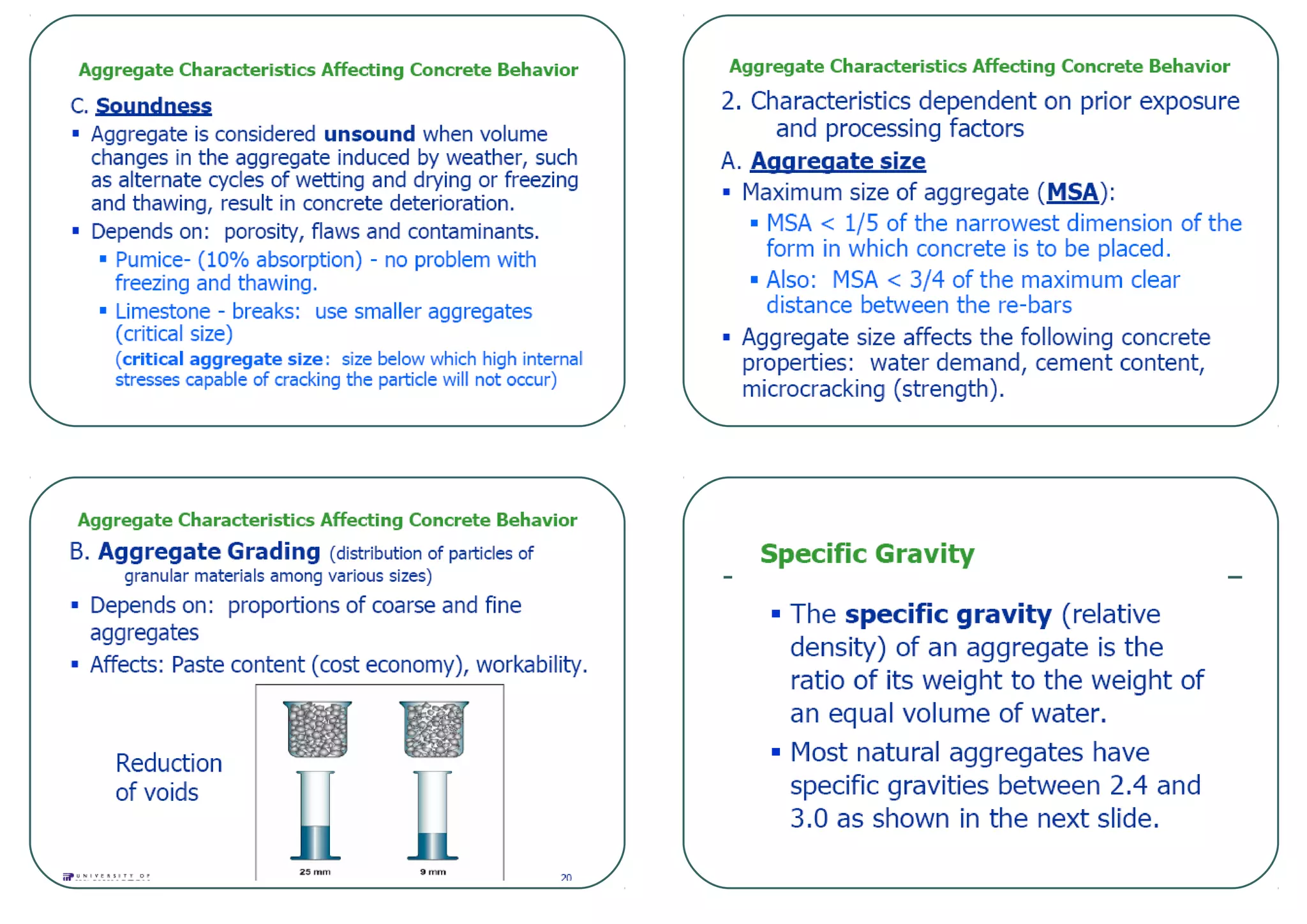

Aggregates are granular materials like sand, gravel, or crushed stone used with water and cement to make concrete. They come in two sizes: fine aggregates smaller than 5 mm and coarse aggregates larger than 5 mm. Aggregates provide strength, reduce cracking, and lower the cost of concrete. They are selected based on being hard, durable, and free of organic materials or other substances that could weaken the concrete. Aggregates are classified by size, manufacturing method, and density. Physical tests are conducted to determine properties like strength, hardness, porosity, and grading.