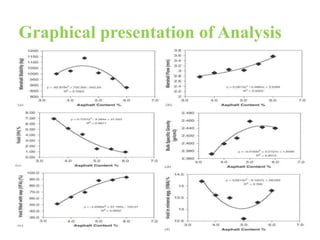

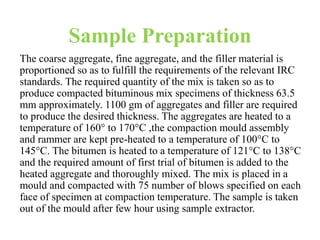

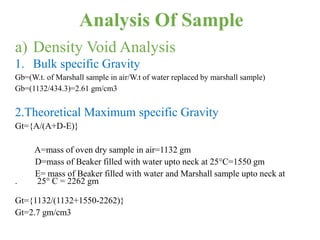

The document describes the Marshall Mix Design Method for designing bituminous pavement mixes. It discusses that the method involves compacting cylindrical specimens of asphalt mixtures and measuring their stability and flow properties under loading. Key steps include selecting aggregate gradations, determining optimum binder content, and testing compacted specimens for density, voids, stability, and flow to meet specifications. The document provides details on sample preparation, conducting analyses for properties like density and voids filled with bitumen, and determining the optimum binder content.

![Density Void Analysis

3. % air void

Va =100[1-(Gb/Gt)]

=100[1-(2.61/2.7)]

Va =3.33 %

4. %Volume of Bitumen

Vb=[Gb x (W4/G4)]

Gb= bulk density of Bitumen=2.61 gm/cm3

W4=% by w.t. of Bitumen in total mix=4.75%

G4=Specific gravity of Bitumen =1.02

Vb=[2.61x(4.75/1.02)]=12.15 %](https://image.slidesharecdn.com/marshallmixdesignmethod-231219143815-5d7bf86d/85/Marshall-mix-design-Method-pptx-10-320.jpg)

![Density Void Analysis

5. %VMA =%Void in mineral Aggregate =[Vb + Va]

=[12.15+3.3]%

VMA =15.45 %

6. %VFB=%Voids Filled With Bitumen

=[100 x(Vb/VMA)]

=[100 x(12.15/15.45)]

VFB=78.64 %](https://image.slidesharecdn.com/marshallmixdesignmethod-231219143815-5d7bf86d/85/Marshall-mix-design-Method-pptx-11-320.jpg)

![Stability Flow Analysis

b) Stability Flow Analysis

1.Stability Value of Marshall Sample

calibration Equation=(4.1963 X - 0.0797)kg

Stability=[(4.1963 x 240)- 0.0797] x {9.8 x (1/1000)}

=9.87 kN

2. Flow Value

Flow Value=( Dial reading x 0.25 )

=(7 x 0.25)

=1.75mm](https://image.slidesharecdn.com/marshallmixdesignmethod-231219143815-5d7bf86d/85/Marshall-mix-design-Method-pptx-12-320.jpg)