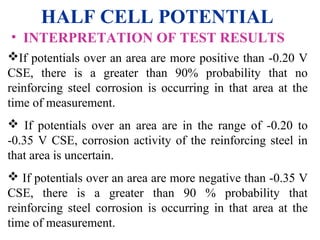

NDT techniques such as rebound hammer testing, ultrasonic pulse velocity testing, and half-cell potential testing can evaluate the strength, durability, homogeneity, and corrosion risk of hardened concrete without damaging it. These methods provide estimates of properties based on correlations with standardized tests and can identify areas of poor quality concrete for repair. NDT is required for post-construction assessment of concrete structures to evaluate their current condition, residual life, and needs for repair or retrofitting.