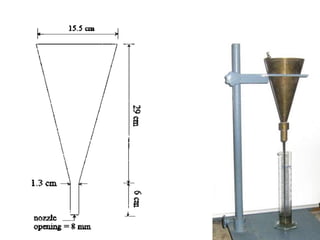

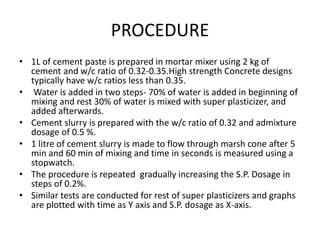

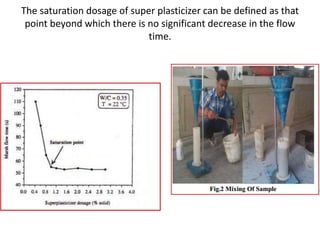

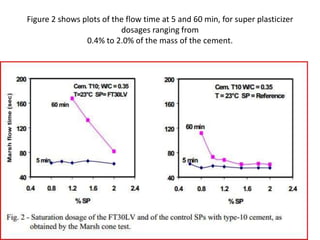

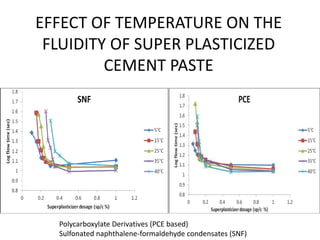

The Marsh cone test is a reliable method for assessing the rheological properties of cements and mortars, indicating viscosity through flow time. It involves measuring the flow of cement paste through a cone-shaped vessel, with variations based on water-to-cement ratios and super plasticizer dosages. The results help determine the optimal super plasticizer content for concrete, facilitating better compatibility and mix design.