1. This document summarizes a student's laboratory experiment analyzing the gradation of fine aggregate through sieve analysis.

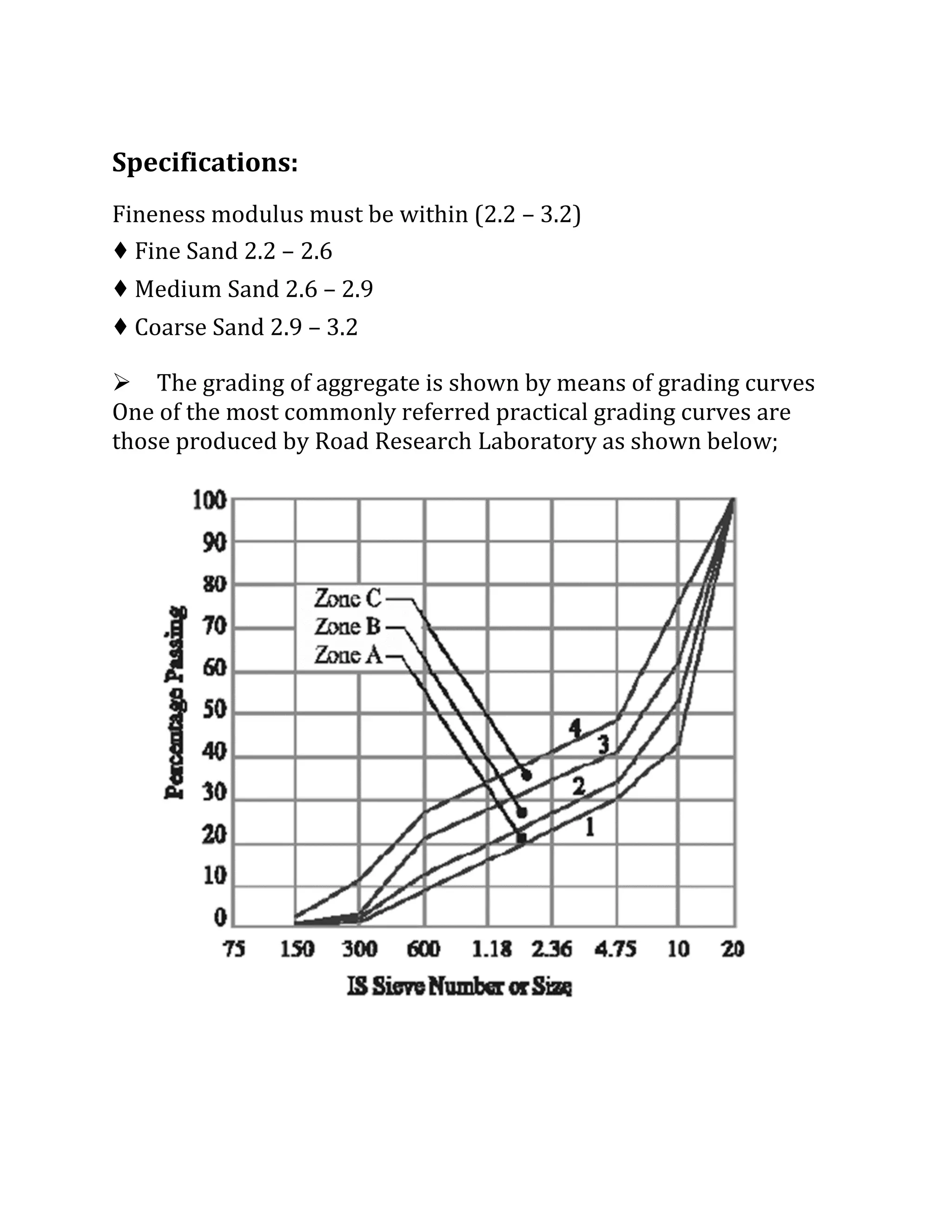

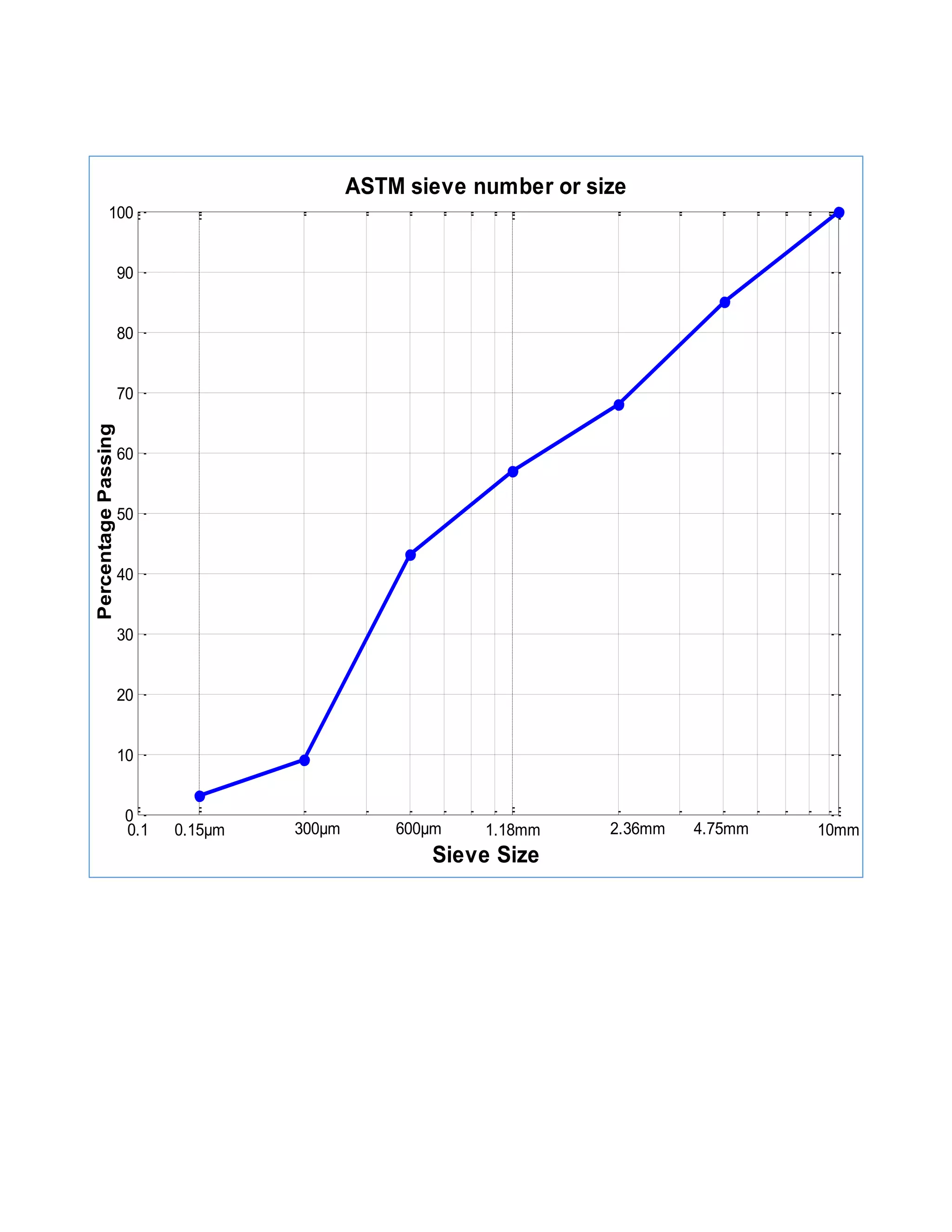

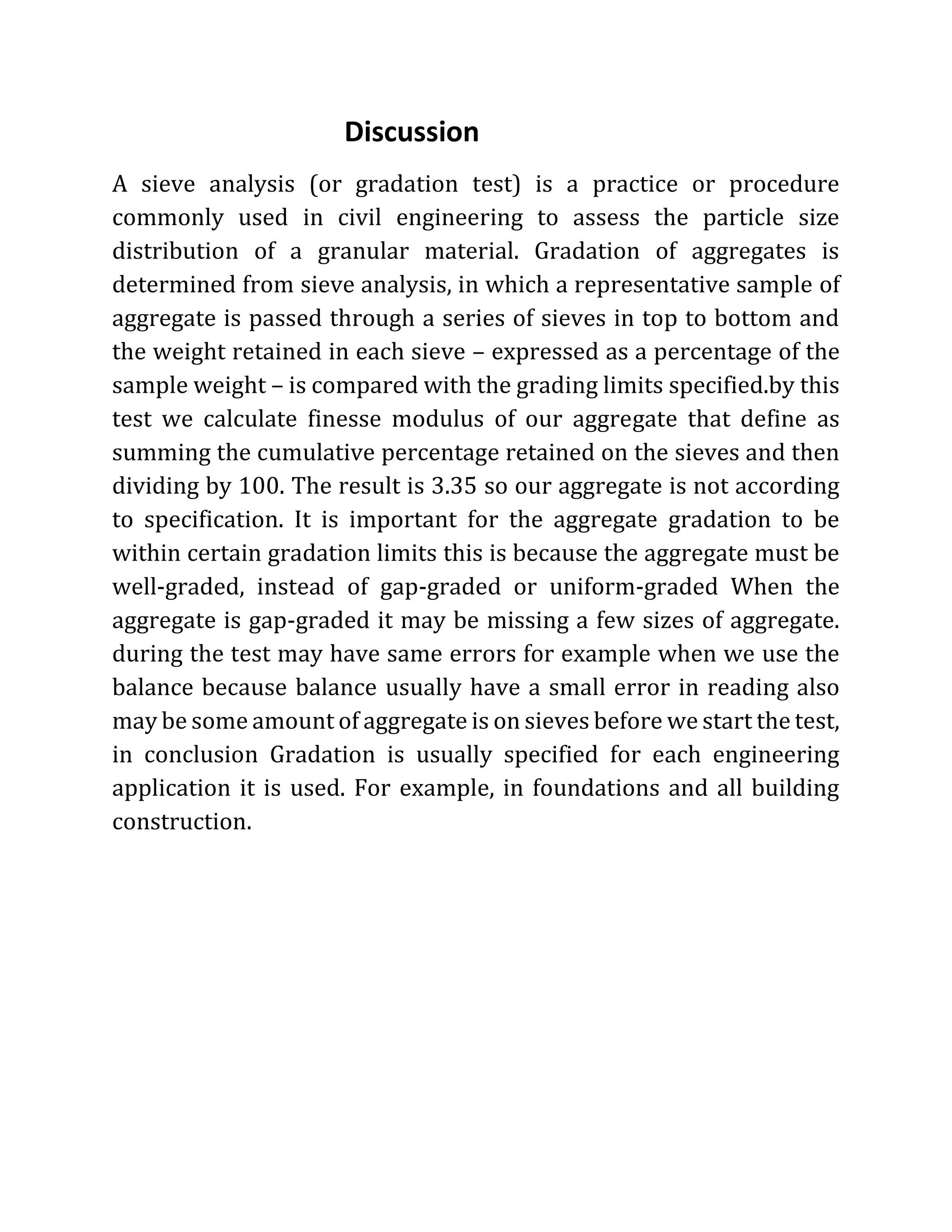

2. Sieve analysis involves separating a dried aggregate sample through a series of sieves to determine the particle size distribution, which is then compared to specifications.

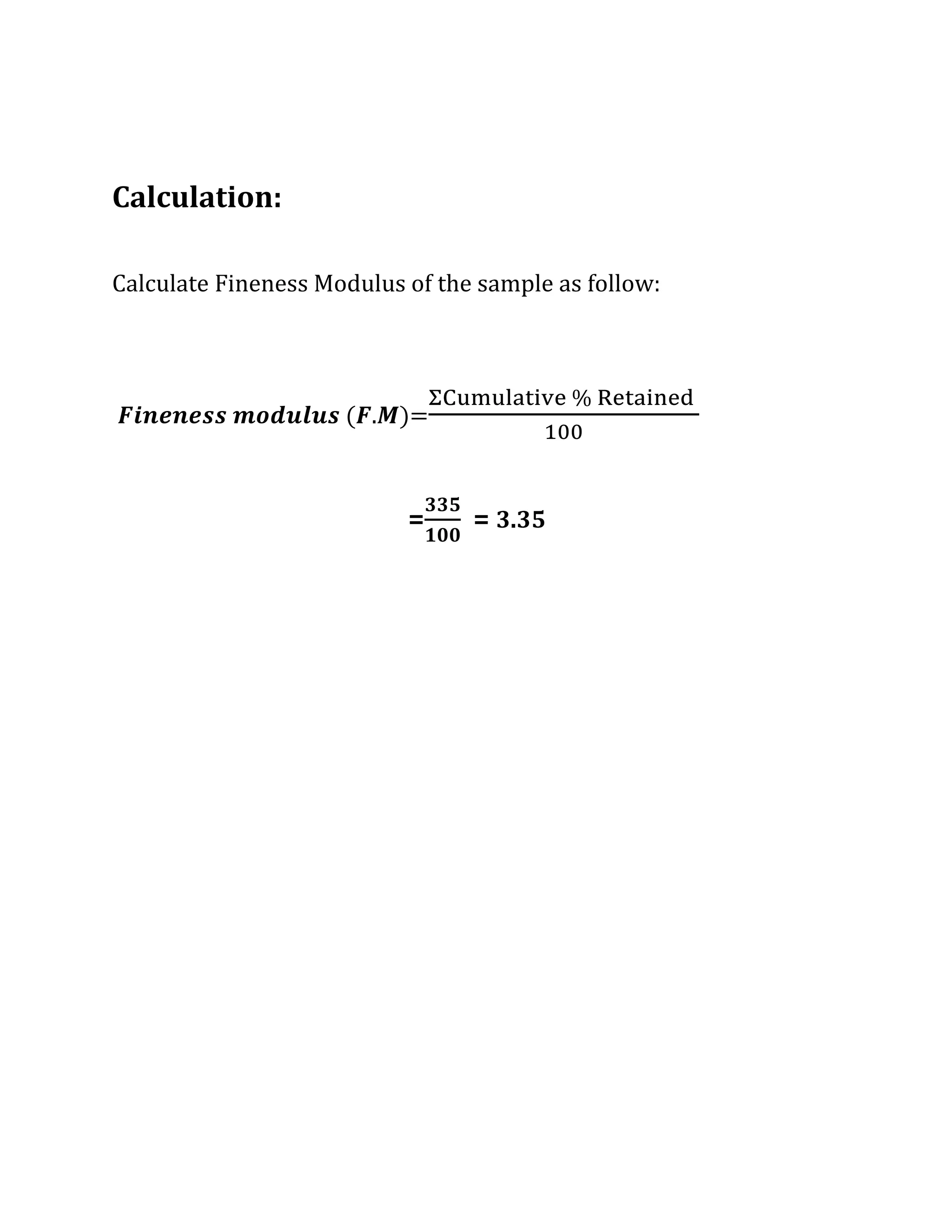

3. The student's results found the fineness modulus of 3.35 for the tested aggregate sample, which is outside the specified range of 2.2-3.2, indicating the aggregate did not meet specifications.