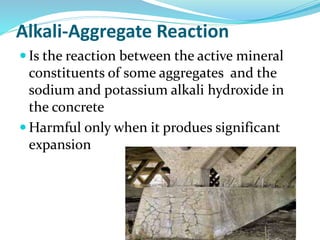

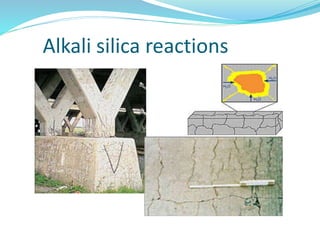

Alkali-aggregate reaction is the reaction between the active mineral constituents of some aggregates and the alkali hydroxides in concrete. It is only harmful when it produces significant expansion. There are two main forms: alkali-silica reaction and alkali-carbonate reaction.

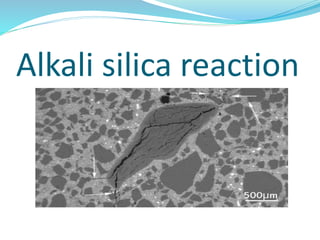

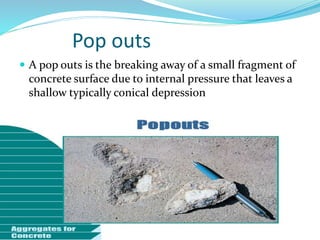

Alkali-silica reaction, also known as ASR, causes cracking in concrete from the reaction between certain reactive minerals or rocks in aggregates and alkalis in cement. It can cause visible symptoms like cracking and pop outs, which are small fragment breakaways leaving shallow depressions.

Alkali-carbonate reaction is influenced by factors like clay or calcite/dolomite content and crystal size in aggregates.