Embed presentation

Downloaded 45 times

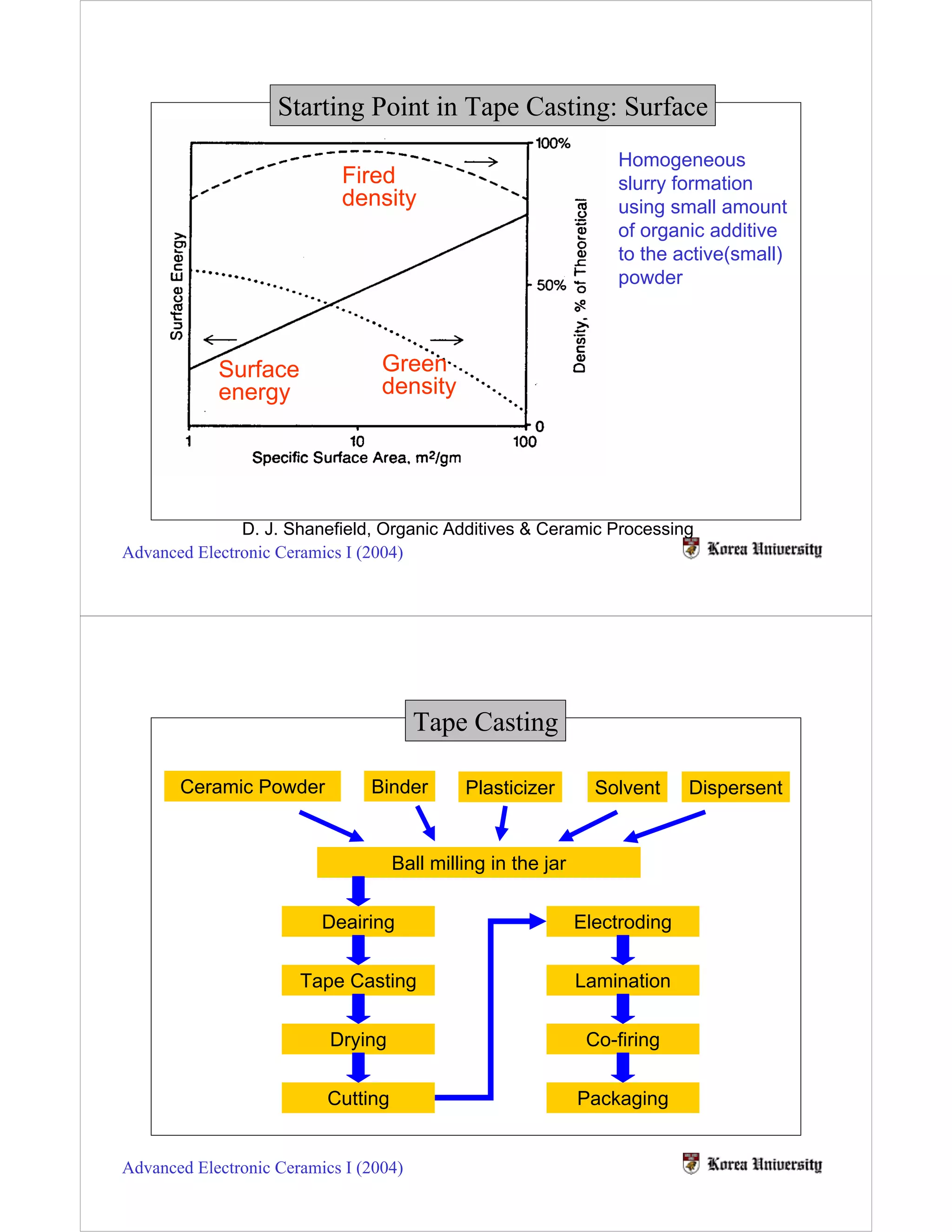

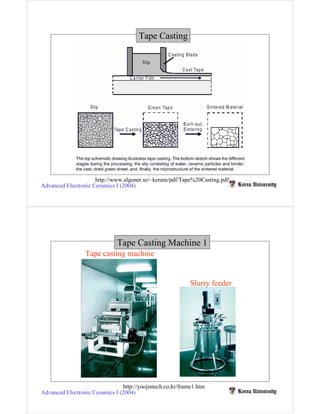

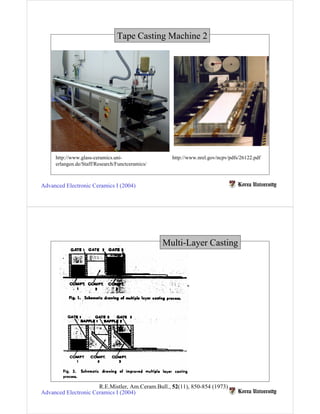

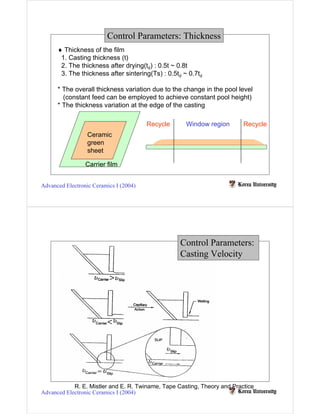

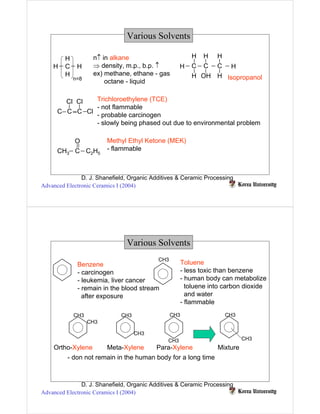

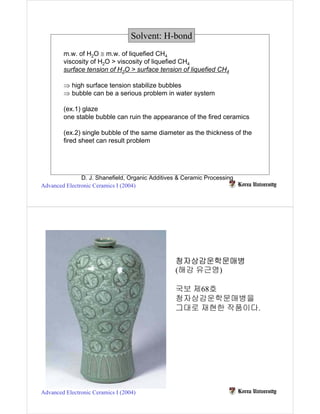

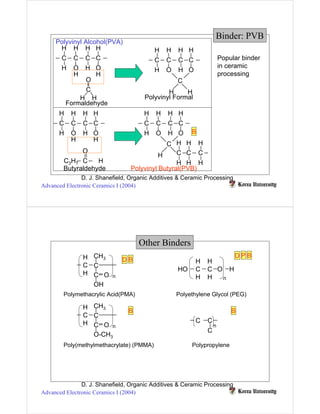

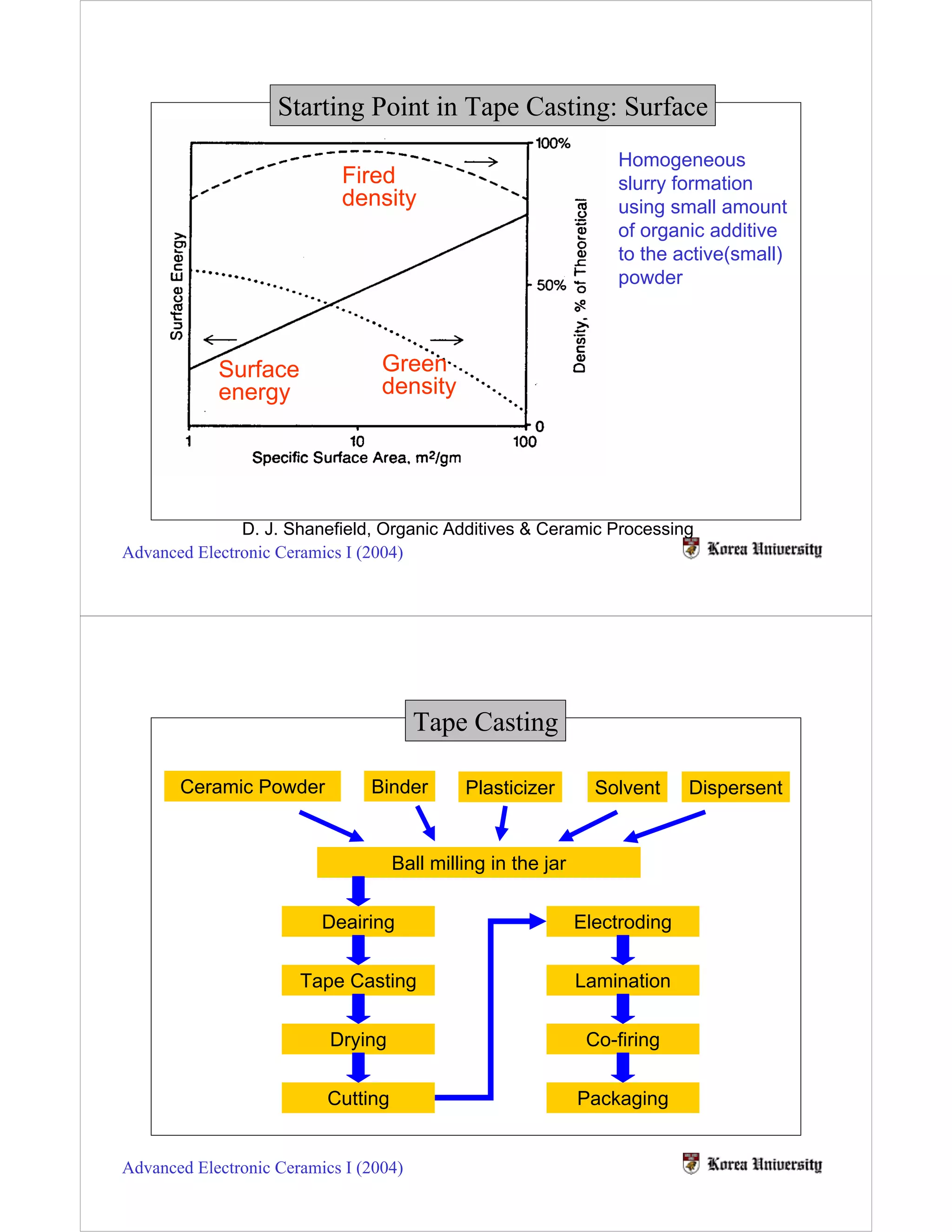

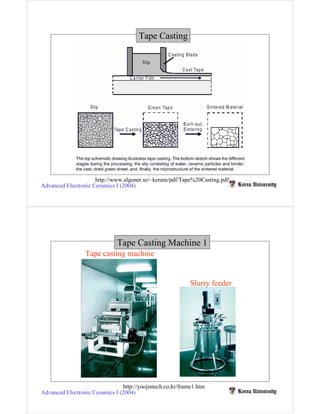

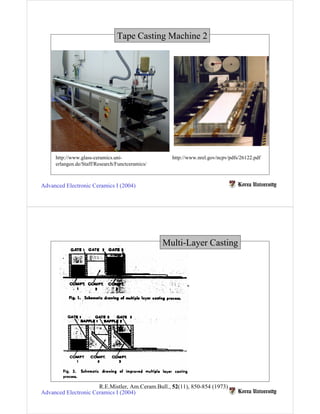

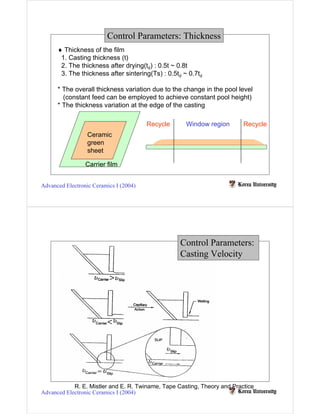

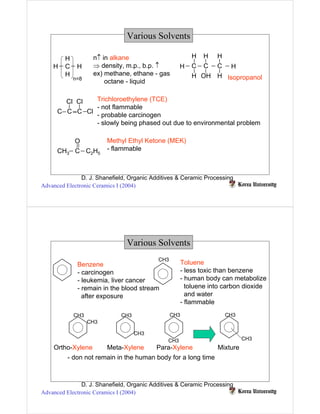

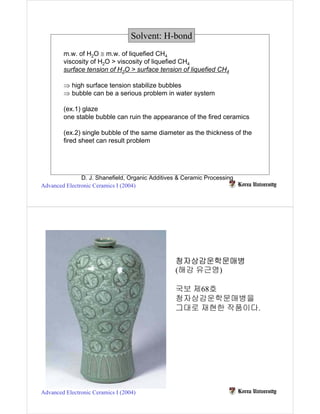

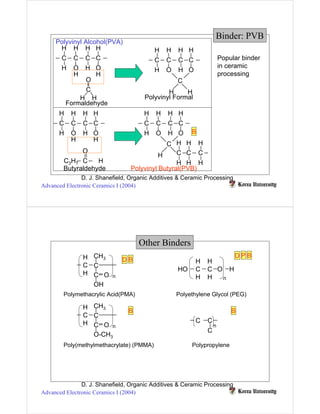

This document provides an overview of the tape casting process for ceramics. It discusses starting with ceramic powder, binder, plasticizer, solvent and dispersant which are ball milled together. The slurry is then deaired, cast into a tape, laminated and dried before being cut and packaged. Key parameters that are controlled include thickness, casting velocity, temperature profile during drying and multi-layer casting. Various solvents, binders and their properties that are commonly used in tape casting are also described.