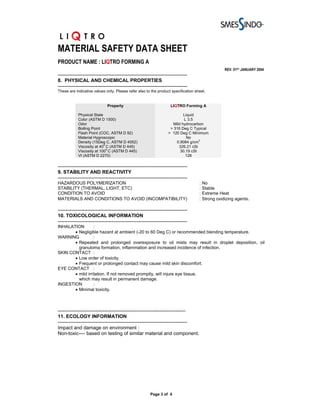

This document is a material safety data sheet for LIQTRO Forming A, a metal forming lubricant. It provides information on product identification, hazards, first aid measures, firefighting measures, accidental release measures, handling and storage, exposure controls, physical and chemical properties, stability and reactivity, toxicological information, ecological information, disposal considerations, and regulatory information. The product contains EP, lubricity and anti-wear additives and provides tool and mold protection during metal forming. It does not contain any hazardous ingredients according to European regulations.