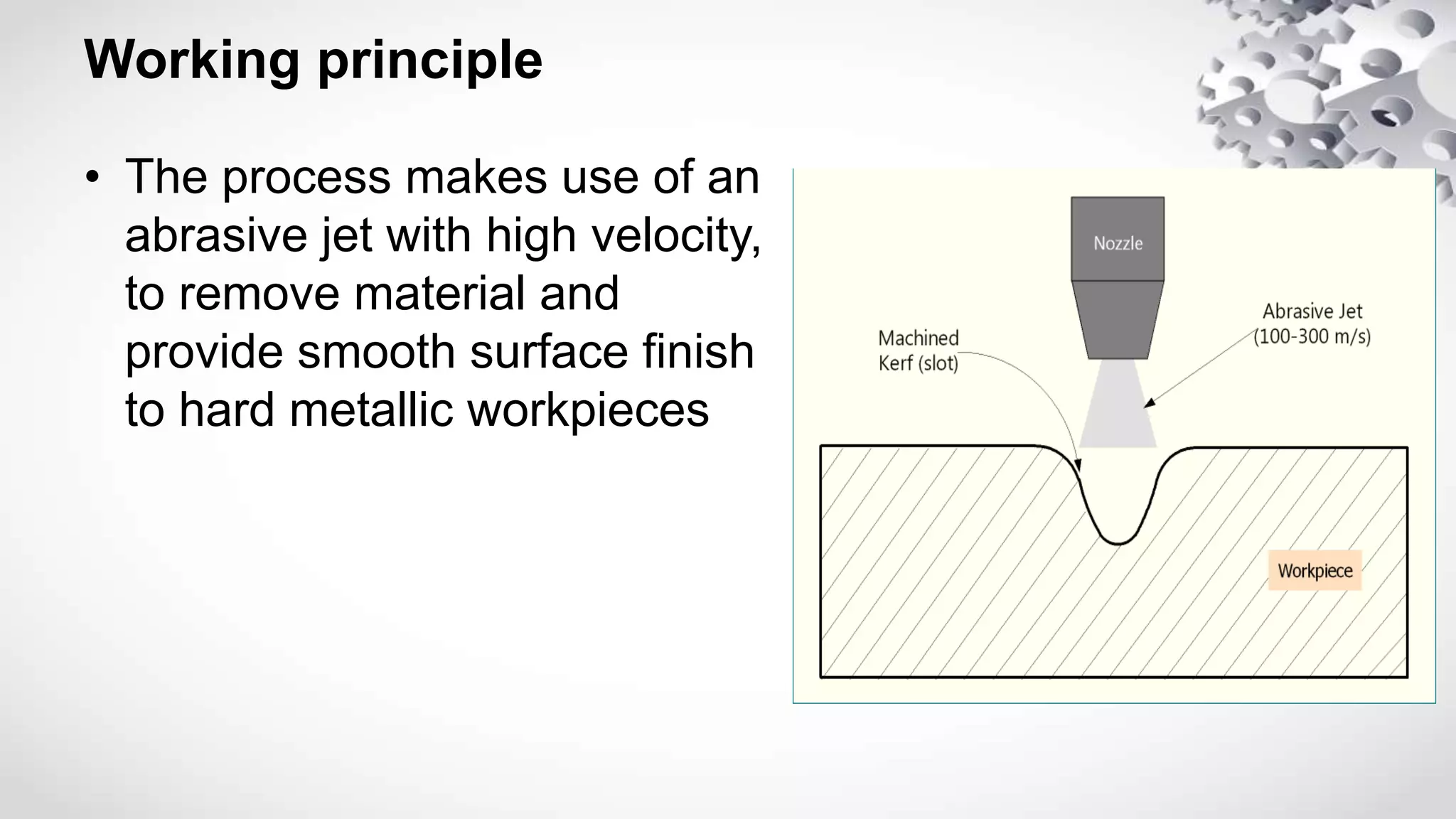

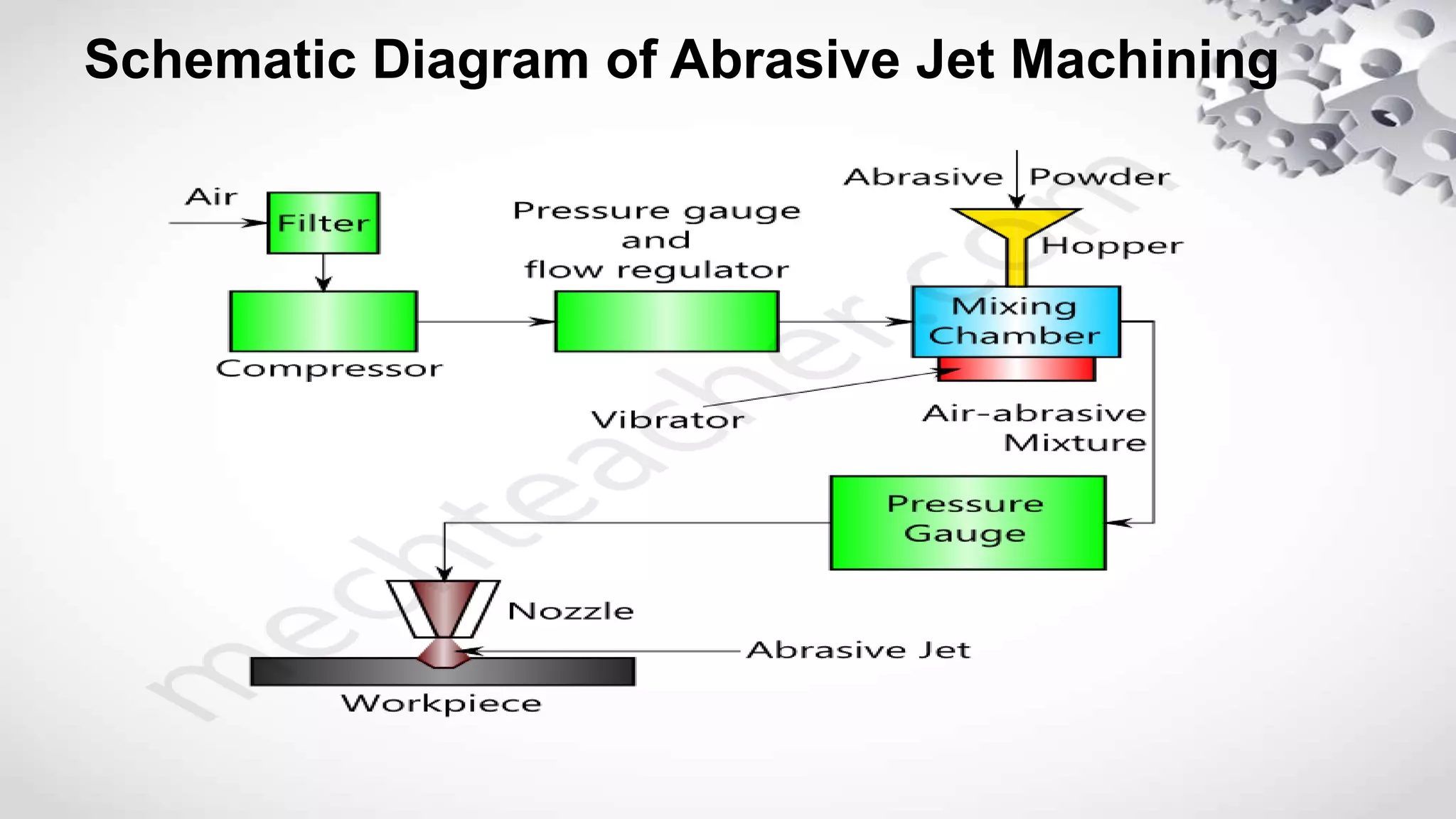

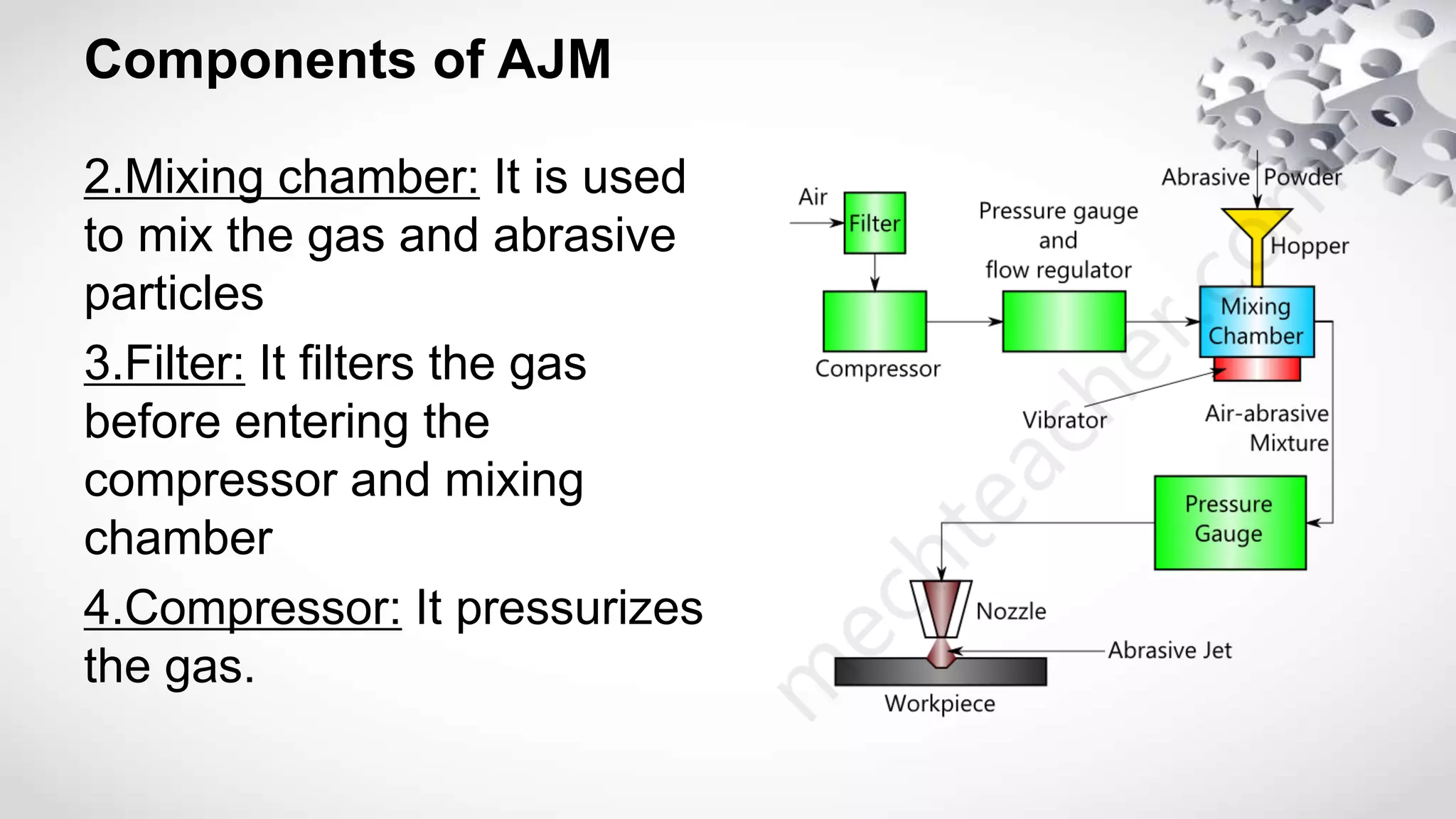

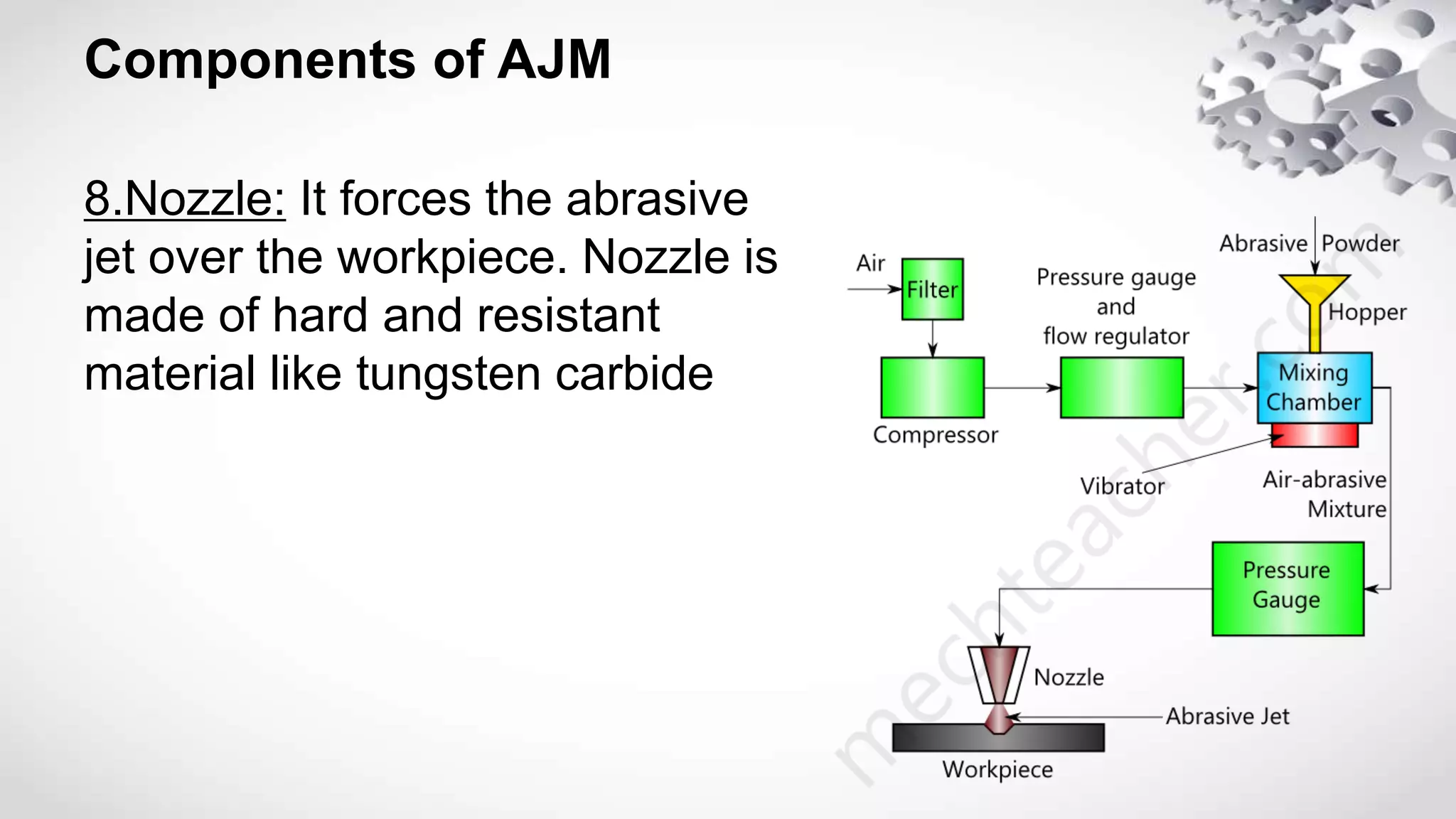

Abrasive jet machining (AJM) is an unconventional machining process that employs a high-velocity abrasive jet to remove unwanted materials and achieve a smooth surface finish on hard metallic workpieces. The process involves components such as an abrasive jet made of gas and particles, a mixing chamber, and a nozzle, with operations like drilling and surface finishing. While AJM offers advantages like a low equipment cost and effective machining of hard materials, it has disadvantages including a low metal removal rate and maintenance requirements for the nozzle.