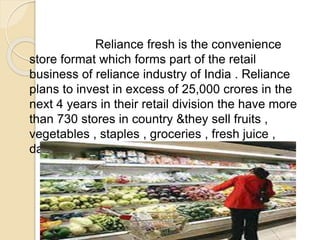

This document provides an overview of the author's visit to the Reliance Retail Limited warehouse in Kondlakoya, India. It first acknowledges those who helped arrange and guide the visit. It then outlines the contents and introduces key concepts like warehouses, warehousing, and warehouse management systems. The next sections describe Reliance Retail's vision, mission, and policies. A detailed account is given of the operations at the Kondlakoya warehouse, including receiving, quality checks, storage, allocation, and dispatch of goods. Specific areas like procurement, quality inspection, and banana ripening are explained in more depth.