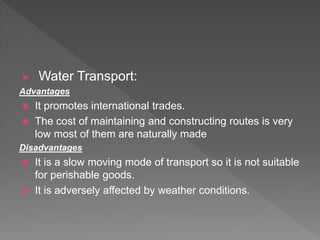

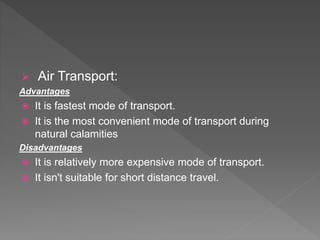

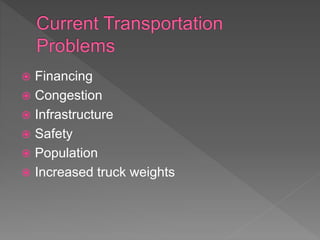

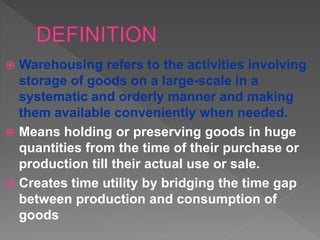

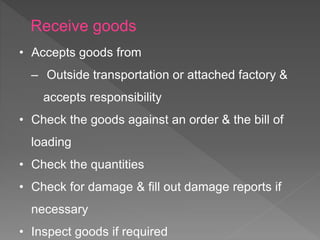

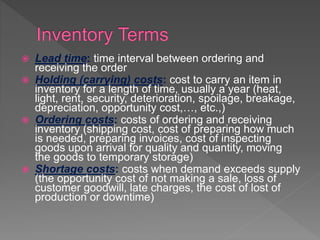

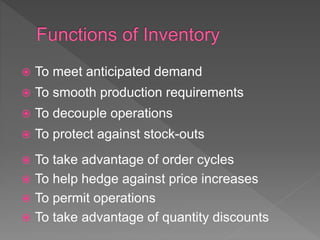

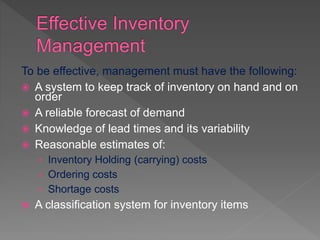

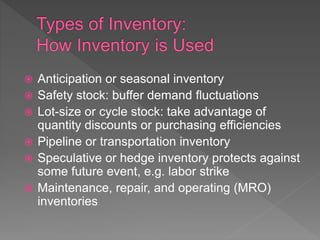

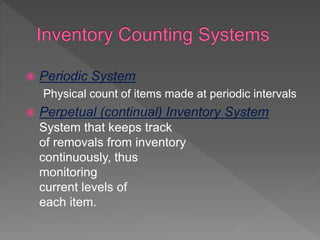

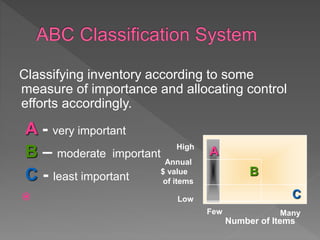

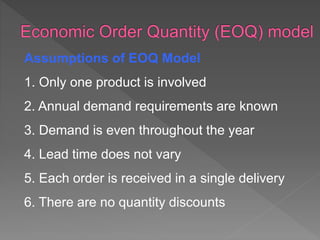

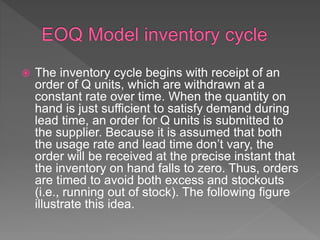

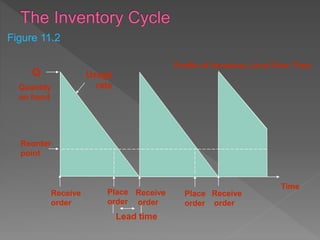

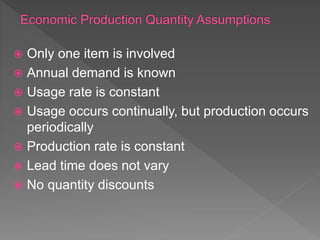

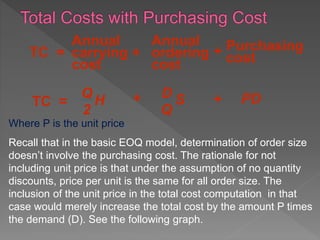

The document discusses the critical role of transportation and warehousing in logistics systems, emphasizing their impact on efficiency, cost, and service quality. It outlines various transportation modes (rail, road, water, air) with their respective advantages and disadvantages, as well as detailed aspects of warehousing, inventory management, and order fulfillment. The document highlights the need for effective inventory management strategies, including economic order quantity models, to balance costs and maintain customer service levels.