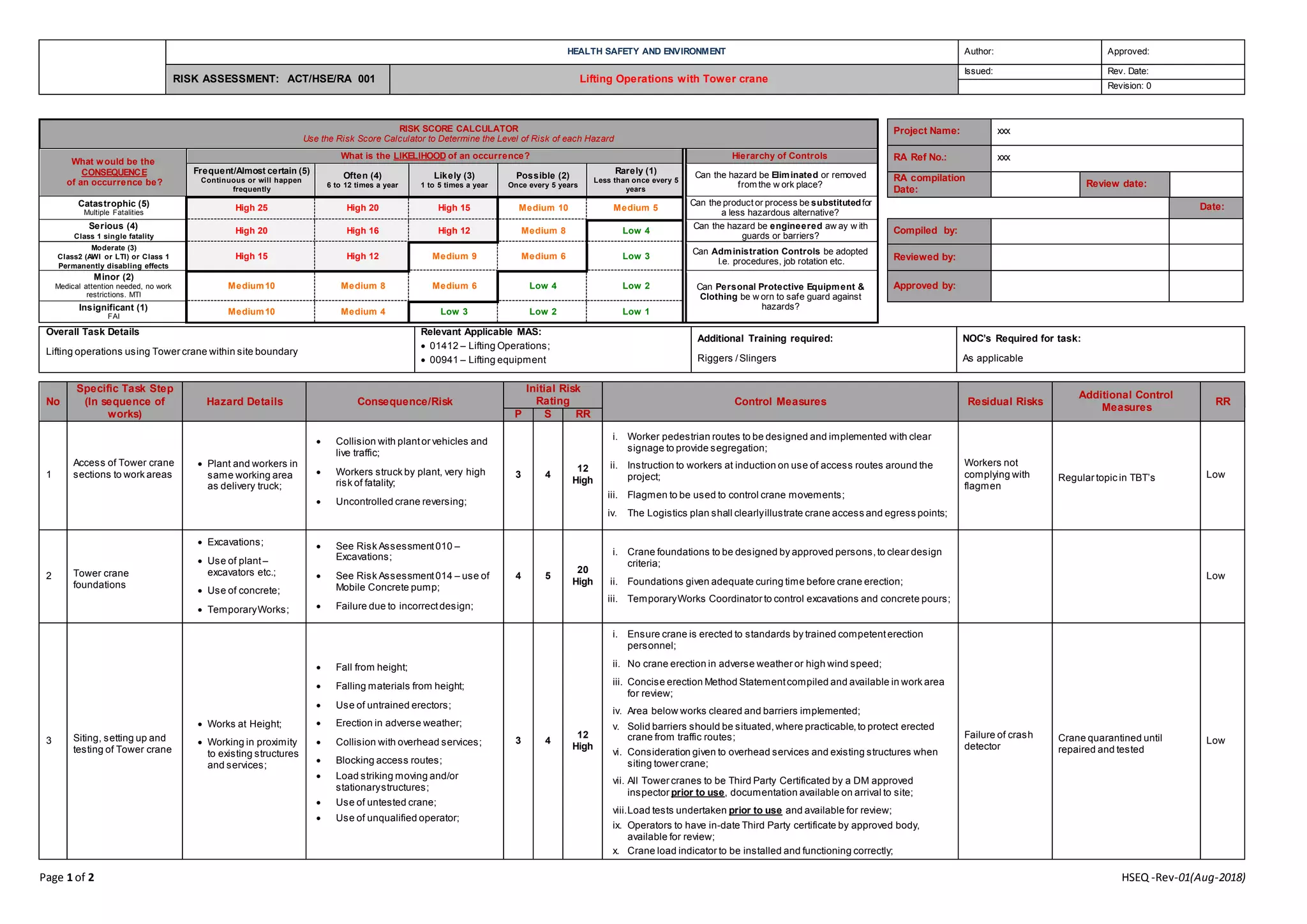

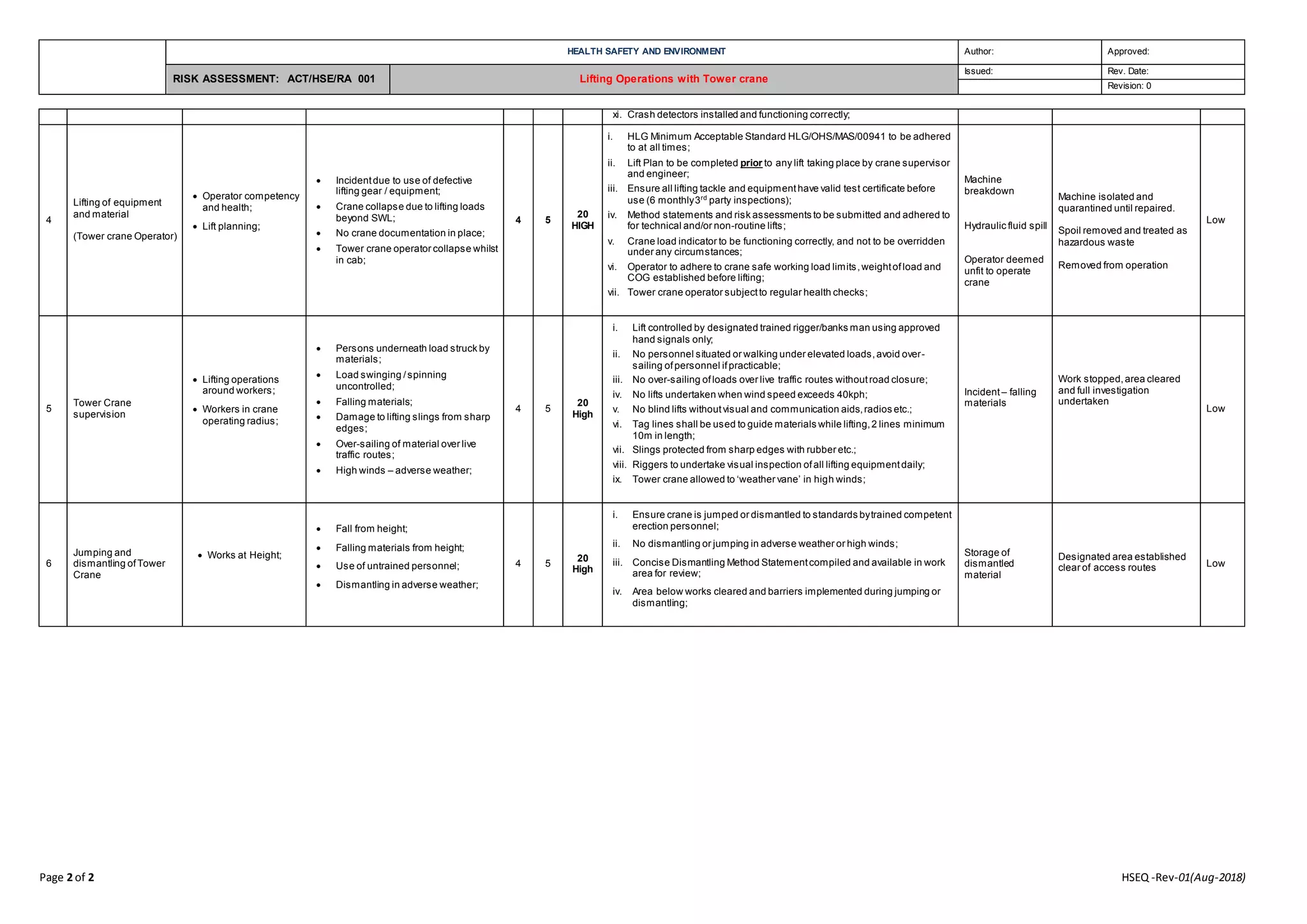

This risk assessment document identifies hazards associated with lifting operations using a tower crane on a construction site. It lists 6 specific tasks: 1) access of crane sections, 2) tower crane foundations, 3) siting, setting up and testing, 4) lifting of equipment and material, 5) tower crane supervision, and 6) jumping and dismantling the tower crane. For each task, potential hazards are identified and an initial risk rating is given. Control measures are then provided to reduce the risks, along with any additional measures. Residual risks after controls are also assessed. The goal is to ensure lifting operations are performed safely.