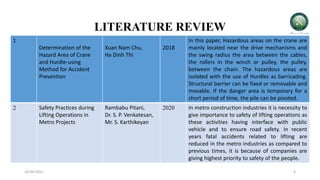

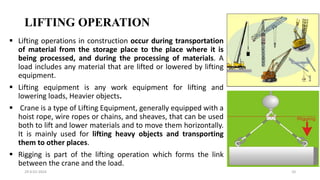

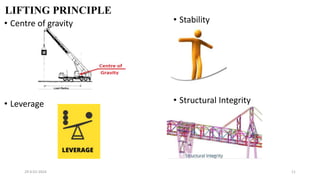

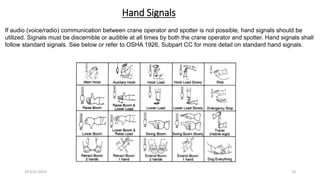

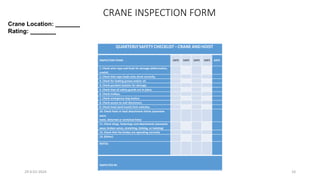

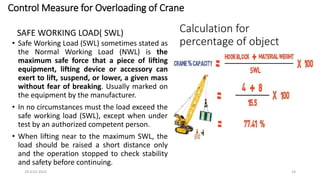

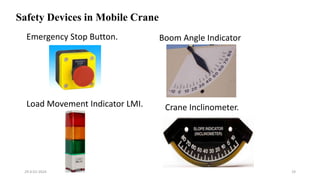

This document provides an overview of a technical seminar presentation on crane and hoist safety. It includes an introduction, types of cranes and hoists, literature review on previous studies of crane hazards, hazards of using cranes, crane inspections, lifting operations standards, principles of lifting, hand signals, a crane inspection form, safe working loads, simple lifting rules, and conclusions. The presentation covers key safety topics like preventing falling objects, communication procedures during lifts, and control measures to prevent overloading or structural failures of cranes.