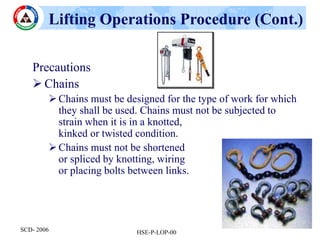

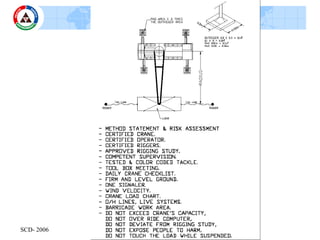

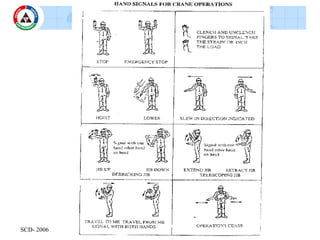

This document outlines procedures for safe lifting operations. It describes the objectives of lifting operation training which are to list major crane accident causes, describe pre-lift planning, state precautions around power lines, and explain ways to eliminate hazards. It details roles and responsibilities of managers, supervisors, riggers and others to ensure lifts are planned and executed safely. The procedures section specifies requirements for lift planning, equipment inspection, communication, and restrictions during high winds or near power lines.