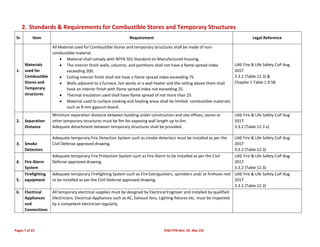

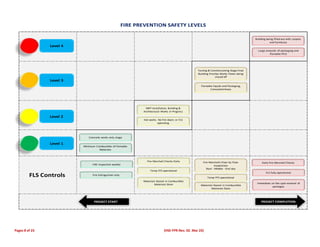

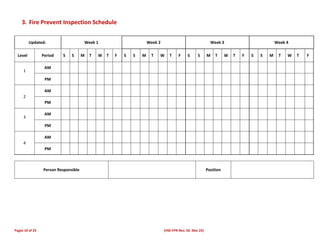

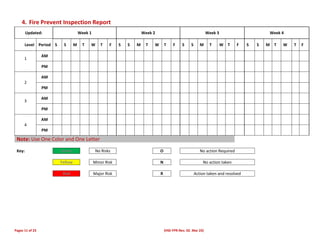

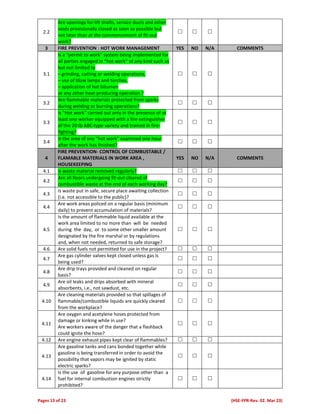

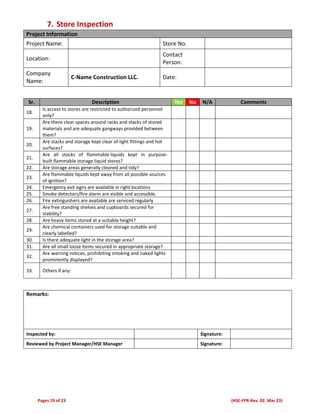

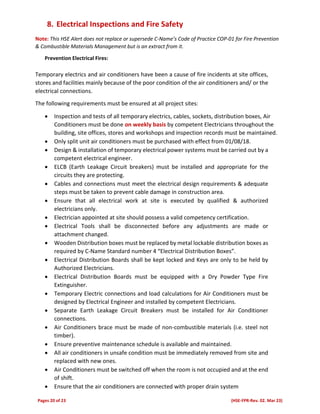

The document outlines a code of practice for fire prevention management, focusing on the handling of combustible materials and electrical inspections to mitigate fire risks in the workplace. It emphasizes the responsibilities of project leaders and HSE managers to enforce fire prevention measures and conduct regular inspections and reporting. Additionally, it details requirements for managing combustible materials, temporary structures, and safety protocols to ensure compliance with regulations and promote a culture of fire safety across construction sites.