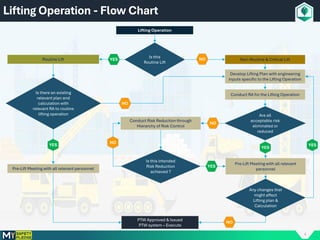

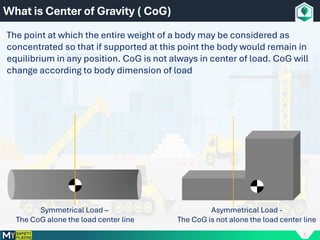

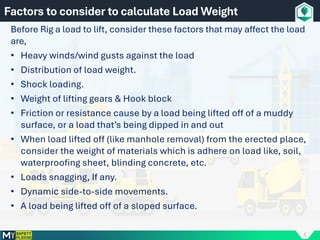

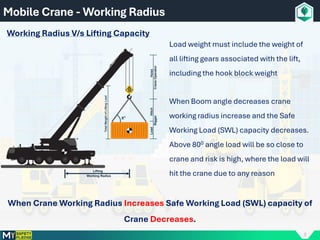

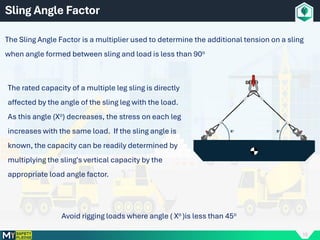

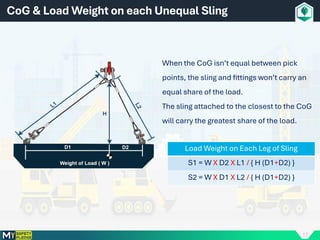

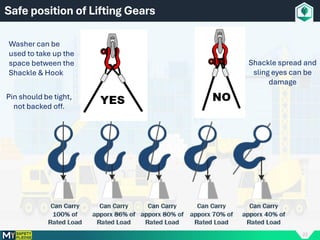

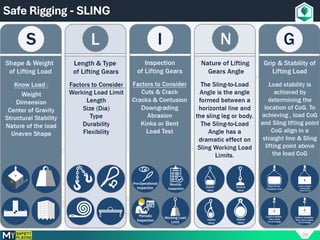

The document outlines essential safety protocols for lifting operations and rigging, emphasizing the importance of protecting human lives, reducing financial losses, and enhancing efficiency. It details various factors that affect lifting operations, such as center of gravity, slinging methods, crane working radii, and the impact of angles on load capacity. Additionally, it provides guidelines for safe lifting, including requirements for outrigger pads, sling tension calculations, and necessary pre-lift precautions.