This document summarizes the die casting process used to produce metal castings. It discusses:

- Die casting forces molten metal into a mold cavity under high pressure (1500-25400 psi).

- Common materials used are zinc, aluminum, magnesium, copper, lead, and tin alloys.

- There are four main steps: die preparation, filling, ejection, and shakeout to separate scrap.

- Different types of die casting machines (hot chamber, cold chamber, vacuum) are used depending on the material and required pressure.

![An engine block with aluminium and magnesium die castings.

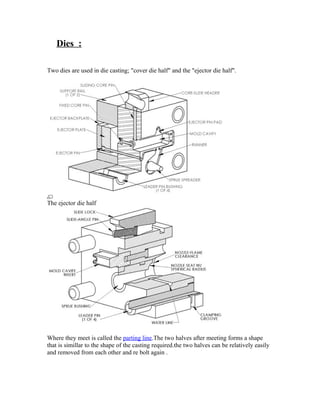

Die casting is a metal casting process that is characterized by forcing molten metal under

high pressure into a mould cavity. The mold cavity is created using two hardened tool

steel dies which are heat ressistant and have been machined into shape and work.The two

dies meet along the parting line , each cavity is machined to have the opposite shape of

each other. There are small vents cut along the edges to allow the air to go out during

the process. If the air is not allowed to go out, it produces blow holes in the castings.

Most die castings are made from non-ferrous metals, specifically zinc, copper,

aluminium, magnesium, lead, pewter and tin based alloys.

Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Process

The following are the four steps in traditional die casting, also

known as high-pressure die casting,[4]

these are also the basis

for any of the die casting variations:

1. Die preparation,

2. Filling

3. Ejection

4. Shakeout

1. The dies are prepared by spraying the mold cavity with lubricant. The lubricant

both helps control the temp of the die and it also assist in the removal of the

casting

2. The dies are then closed and molten metal is injected into the dies under high

pressure (1500 – 25400 psi).As metal flows under high pressure in pressure die

casting, within a fraction of second the liquid alloys fills the entire die including](https://image.slidesharecdn.com/8-140622192905-phpapp02/75/IIIE-SECTION-A-MANUFACTURING-TECHNOLOGY-NOTES-8-die-castings-1-2048.jpg)

![all minute cavities, therefore intricate parts can be produced succesfully. Once

the mold cavity is filled, the pressure is maintained until the casting solidifies.

3. The dies are then opened and the shot (shots are different from castings because

there can be multiple cavities in a die, yielding multiple castings per shot) is

ejected by the ejector pins.

4. The shakeout involves separating the scrap, which includes the gate, runners,

sprues and flash, from the shot. This is often done using a special trim die in a

power press or hydraulic press. Other methods of shaking out include sawing and

grinding. A less labor-intensive method is to tumble shots if gates are thin and

easily broken; separation of gates from finished parts must follow. This scrap is

recycled by remelting it.[9]

The yield is approximately 67%

Gravity Die casting

In gravity die casting no external force is applied other than the head of the liquid.A

feeder is incorporated so that when the level of metal in the feeder is above that in the

highest point of the casting, head of liquid in feeder forces the metal into all parts of the

mould cavity. The feeder is cut off after solidification. It is usually used for shorter

production runs.

Casting materials :

The main die casting alloys are: zinc, aluminium, magnesium, copper, lead, and tin;

although uncommon, ferrous die casting is also possible.[5]

Specific die casting alloys

include: ZAMAK; zinc aluminium; aluminium to, e.g. The Aluminum Association (AA)

Depending upon the melting temp of the alloys there suitability for die casting they are

classified as high MP ( above 500 deg C) and low MP( Below 500 deg C)

Under the low temp category come Zn, Sn, Pb based alloys and these have advantages of

lower die maintainance cost and lower cost of production.

Under high temp category comes Al and copper based alloys . these alloys create lot of

difficulties in die castings because of destructive effects of high temperature.The erosion

of dies increases with temp and at high temp the molten alloy has solvent action on the

machine part and dies.

Al has more pronounced effect.

Zn has emerged as the materials that possess best overall properties for die casting.With

Zn we can make castings weighing as high as 20 Kgs and as thin as 1,25 wall thickness.

• Zinc: the easiest alloy to cast; high ductility; high impact strength; easily plated;

economical for small parts; promotes long die life.

• Aluminium: lightweight; high dimensional stability for complex shapes and thin

walls; good corrosion resistance; good mechanical properties; high thermal and

electrical conductivity; retains strength at high temperatures.

• Magnesium: the easiest alloy to machine; excellent strength-to-weight ratio;

lightest alloy commonly die cast.](https://image.slidesharecdn.com/8-140622192905-phpapp02/85/IIIE-SECTION-A-MANUFACTURING-TECHNOLOGY-NOTES-8-die-castings-2-320.jpg)

![• Copper: high hardness; high corrosion resistance; highest mechanical properties

of alloys die cast; excellent wear resistance; excellent dimensional stability;

strength approaching that of steel parts.

• Lead and tin: high density; extremely close dimensional accuracy; used for

special forms of corrosion resistance. Such alloys are not used in foodservice

applications for public health reasons.

Maximum weight limits for aluminium, brass, magnesium, and zinc castings are

approximately 70 pounds (32 kg), 10 lb (4.5 kg), 44 lb (20 kg), and 75 lb (34 kg),

respectively.[7]

The material used defines the minimum section thickness and minimum draft required for

a casting as outlined in the table below. The thickest section should be less than 13 mm

(0.5 in), but can be greater.

Die casting machines :

A die casting machine is a heavy rigid machine which supports the die halves, one

moving one into allignmnet with other. It must have sufiicient strength to lock and hold

the dies together under considerable pressure, so that no leakage occurs at the parting

line. The machine should resist the injection pressure.Very little deflection or streching

can be allowed in any part of the machine.

The necessary parts that a die casting machine should have are :

1. Die cast machanism for opening and closing the dies.

2. Mens of forcing the metal in the die.

3. device to keep the movable die half pressed untill the solidification of the molten

metal takes place.

4. Arrangement for automatic insertion and removal of cores from die casting

5. Ejector pins to eject casting from the die.

There are three types of die casting machines:

1. Hot chamber die casting machine:

The metal melting unit forms an integral part of the machine.It mainly consists of

a hot chamber and a goose neck shaped metal container made of CI.This machine is

mainly used for low MP alloys like Zn etc. Metals and alloys having High MP and

metals having affinity for iron cann’t be cast by this machine which othervice attack

the dies and damage the machine.](https://image.slidesharecdn.com/8-140622192905-phpapp02/85/IIIE-SECTION-A-MANUFACTURING-TECHNOLOGY-NOTES-8-die-castings-3-320.jpg)