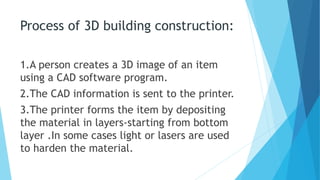

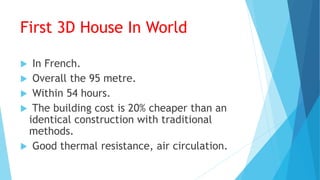

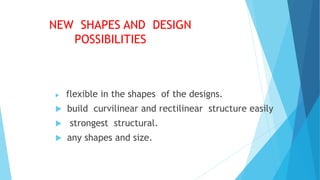

This document discusses 3D printing technology in construction. It provides an overview of 3D printing and how the process works to build objects layer by layer. The history and first uses of 3D printing in construction are described, including building the first 3D printed house in France in 24 hours. Comparisons are made between 3D printing and traditional construction methods, noting advantages of 3D printing like lower costs, waste, and time. Potential future benefits are outlined, such as new design possibilities, precision, and remote construction. Examples of a 3D printed bridge and canal are provided. Disadvantages and challenges are also acknowledged.