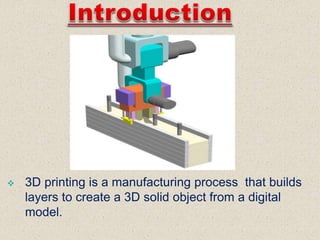

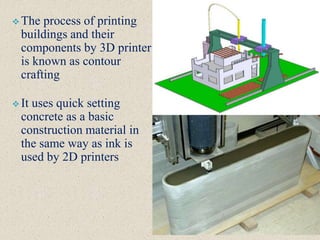

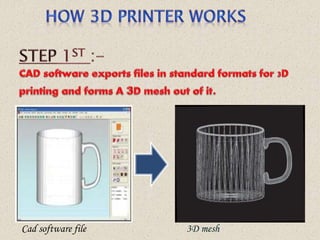

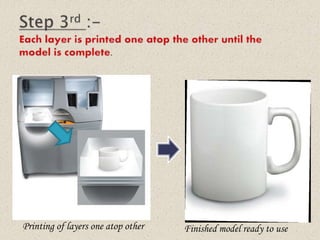

3D printing is a process that builds 3D objects layer by layer from a digital model. This process, known as contour crafting, can now print entire buildings using concrete in a similar way that 2D printers use ink. Contour crafting allows for the insertion of structural components, plumbing, wiring, and devices during the printing process. With 3D printers, buildings can now be constructed quickly from a digital design file without the need for construction labor. This new construction technique is faster, more accurate, and more sustainable than traditional methods.