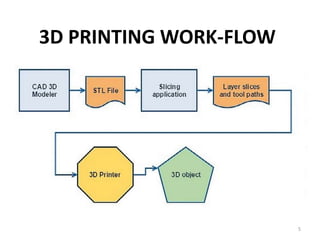

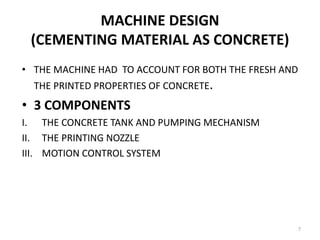

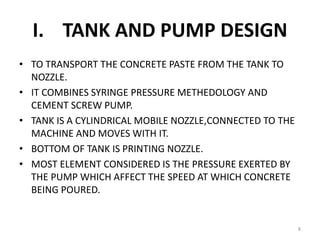

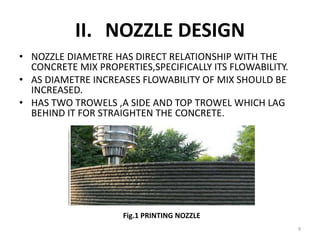

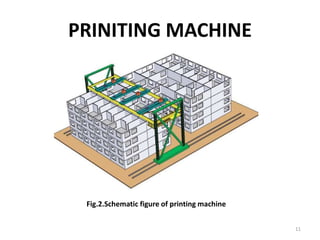

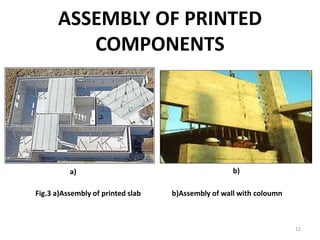

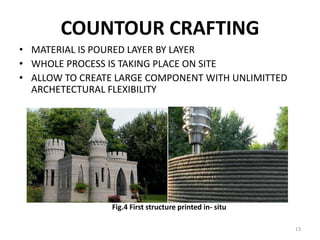

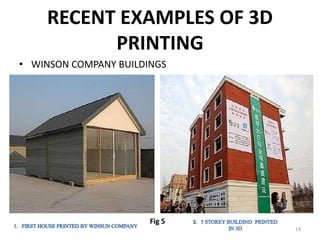

The document discusses the workflow and design aspects of 3D concrete printing, detailing the machine's components including the concrete tank, pumping mechanism, and nozzle design. It highlights the process of contour crafting, which allows for on-site creation of large structures with architectural flexibility, while also recognizing the benefits like time optimization and reduced material waste. The document concludes that while 3D printing in construction is a new approach with potential limitations, it presents opportunities for more complex building designs.