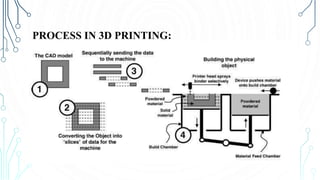

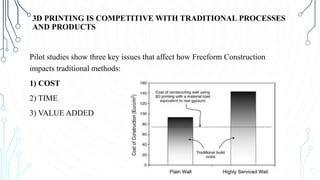

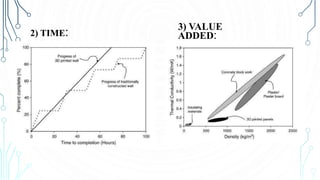

This document contains information about 3D printing from two individuals - Anjali Deshmukh and R. Arun, both from the Civil Engineering department. It discusses the benefits of 3D printing such as reducing costs by finding design errors earlier. 3D printing allows functional product models to be created, helping identify issues like poor fit or ergonomics. The document also examines why 3D printing has not been applied to building construction yet and outlines some of the advantages it could provide such as reduced costs and timelines as well as increased design freedom and functional integration.