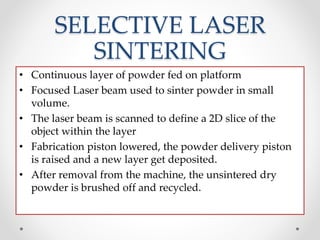

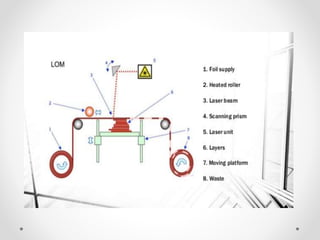

3D printing, also known as additive manufacturing, is a process that creates solid 3D objects from a digital file by building up successive layers of material. It allows for complex shapes to be produced and reduces design constraints. Common 3D printing methods include stereolithography, fused deposition modeling, selective laser sintering, and laminated object manufacturing. 3D printing offers advantages like rapid prototyping and reduced waste but also has disadvantages such as higher costs and slower production speeds. Future applications of 3D printing include use in the medical, aerospace, fashion and food industries.