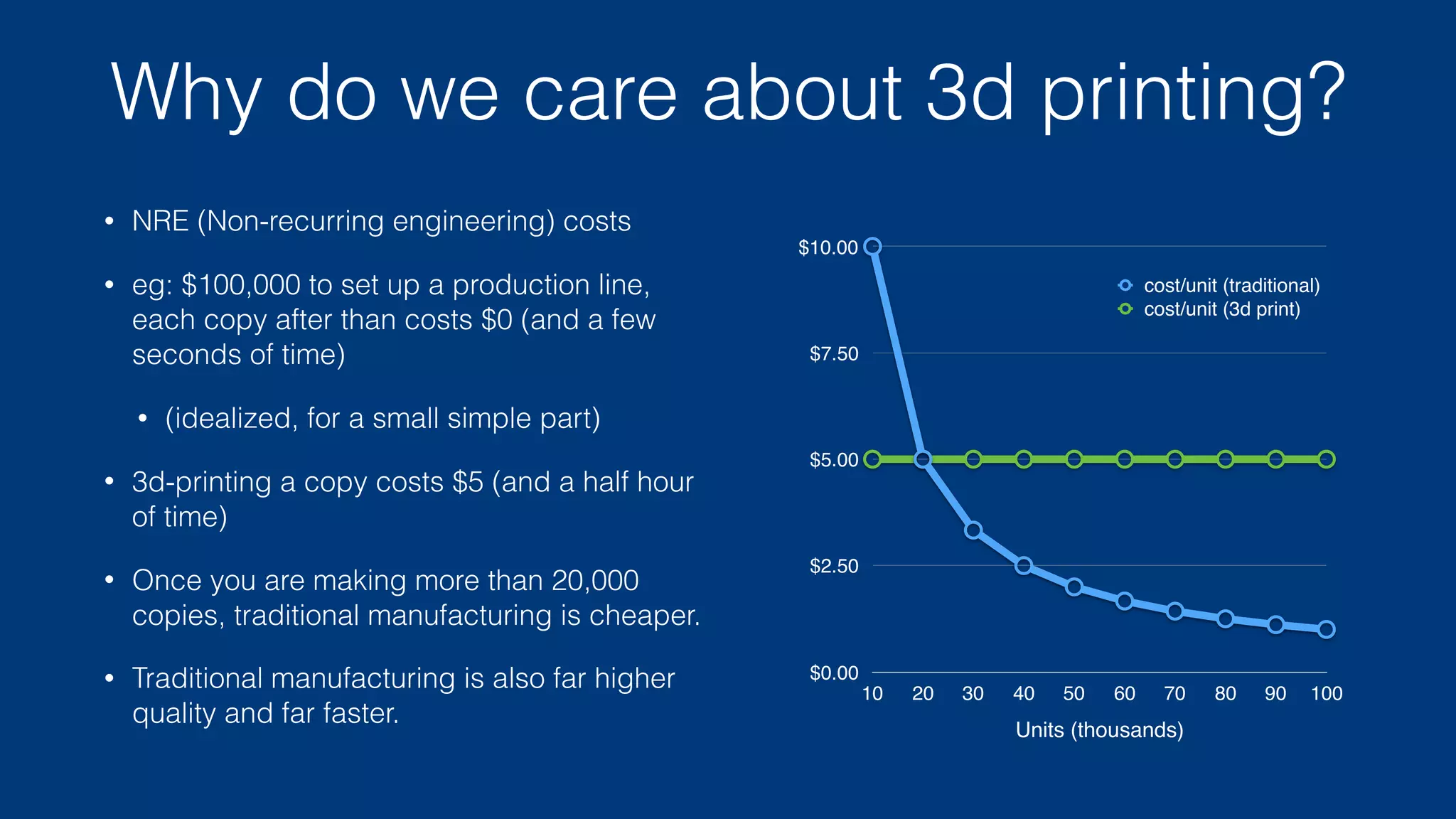

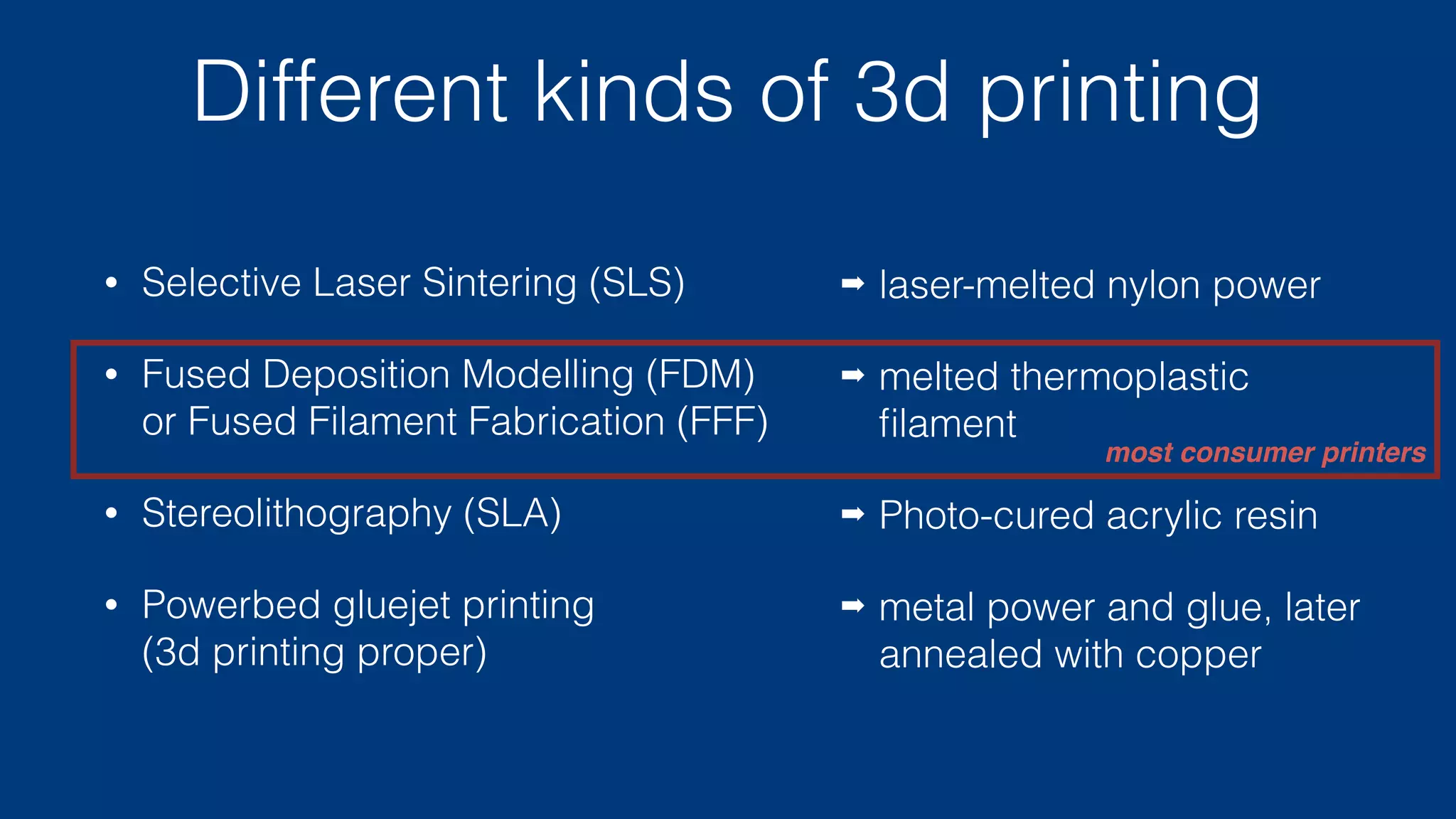

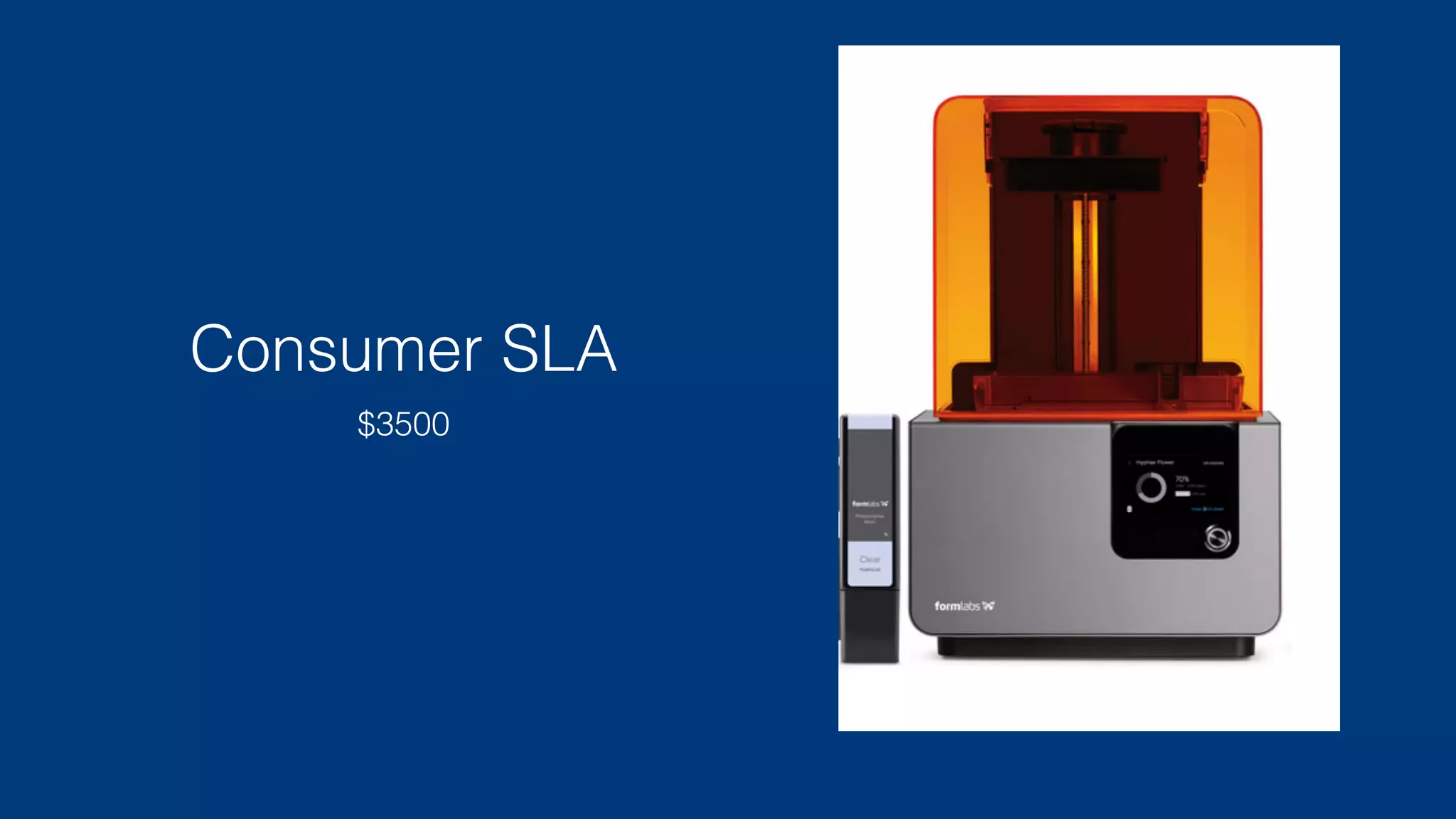

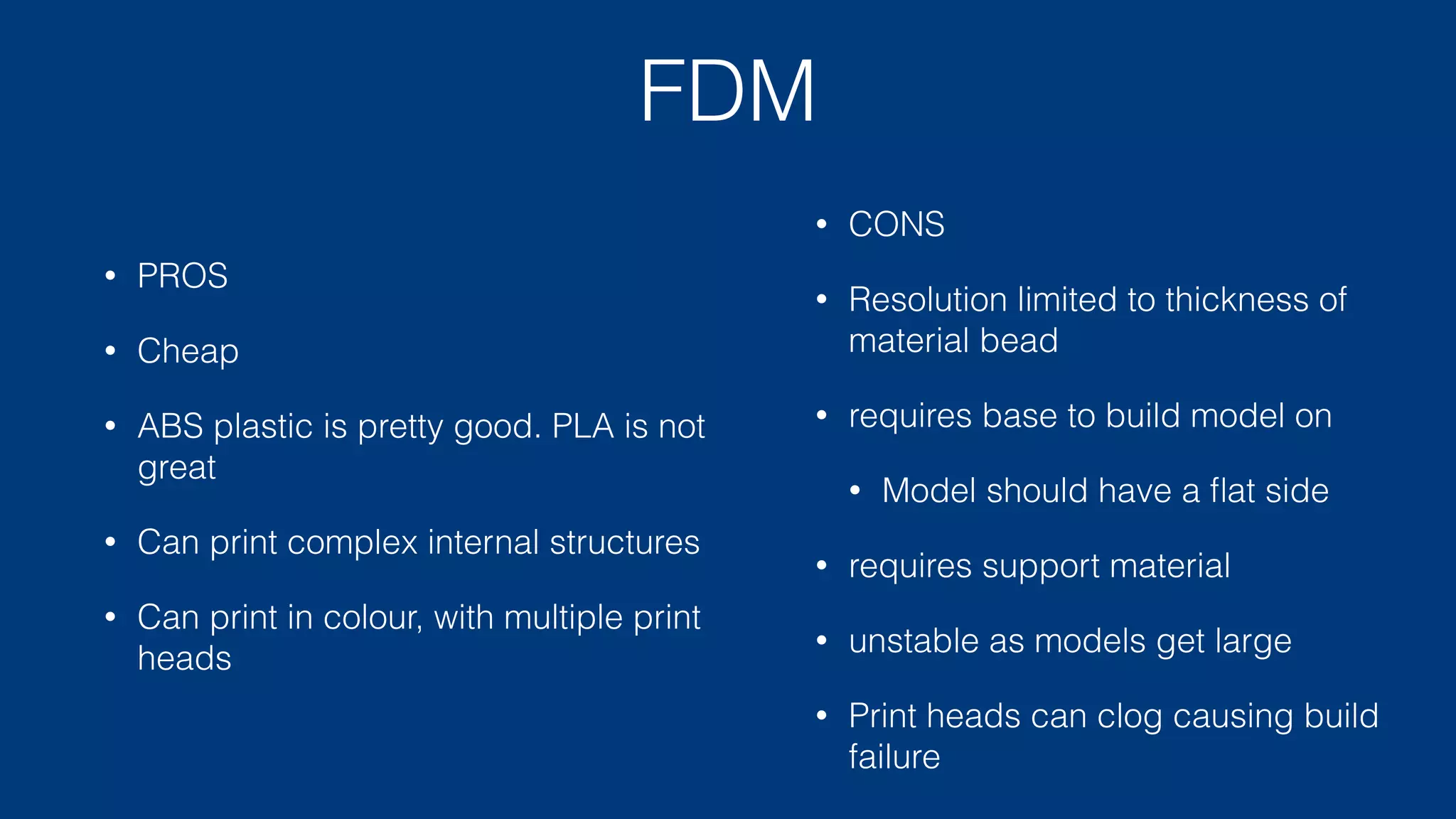

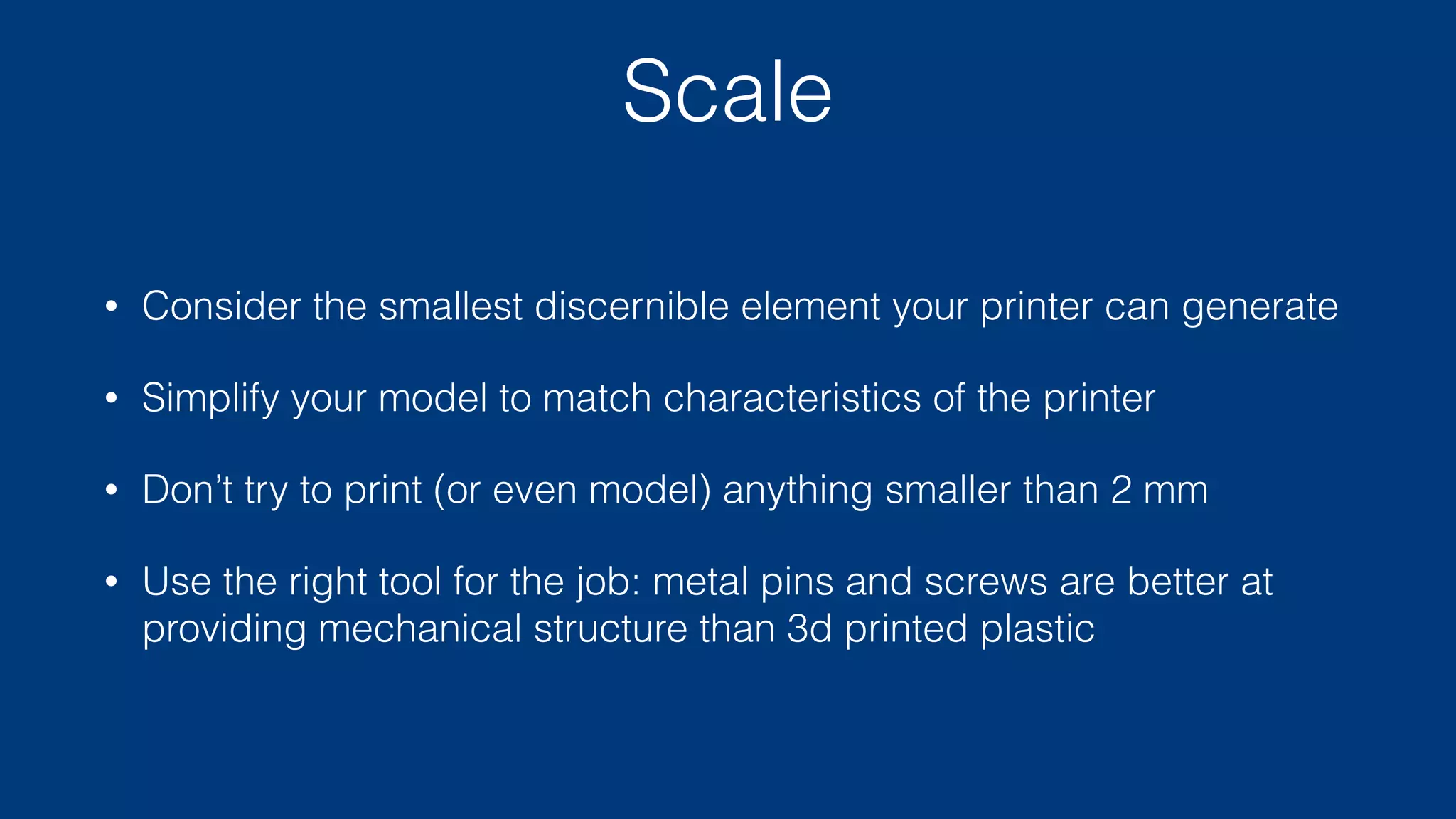

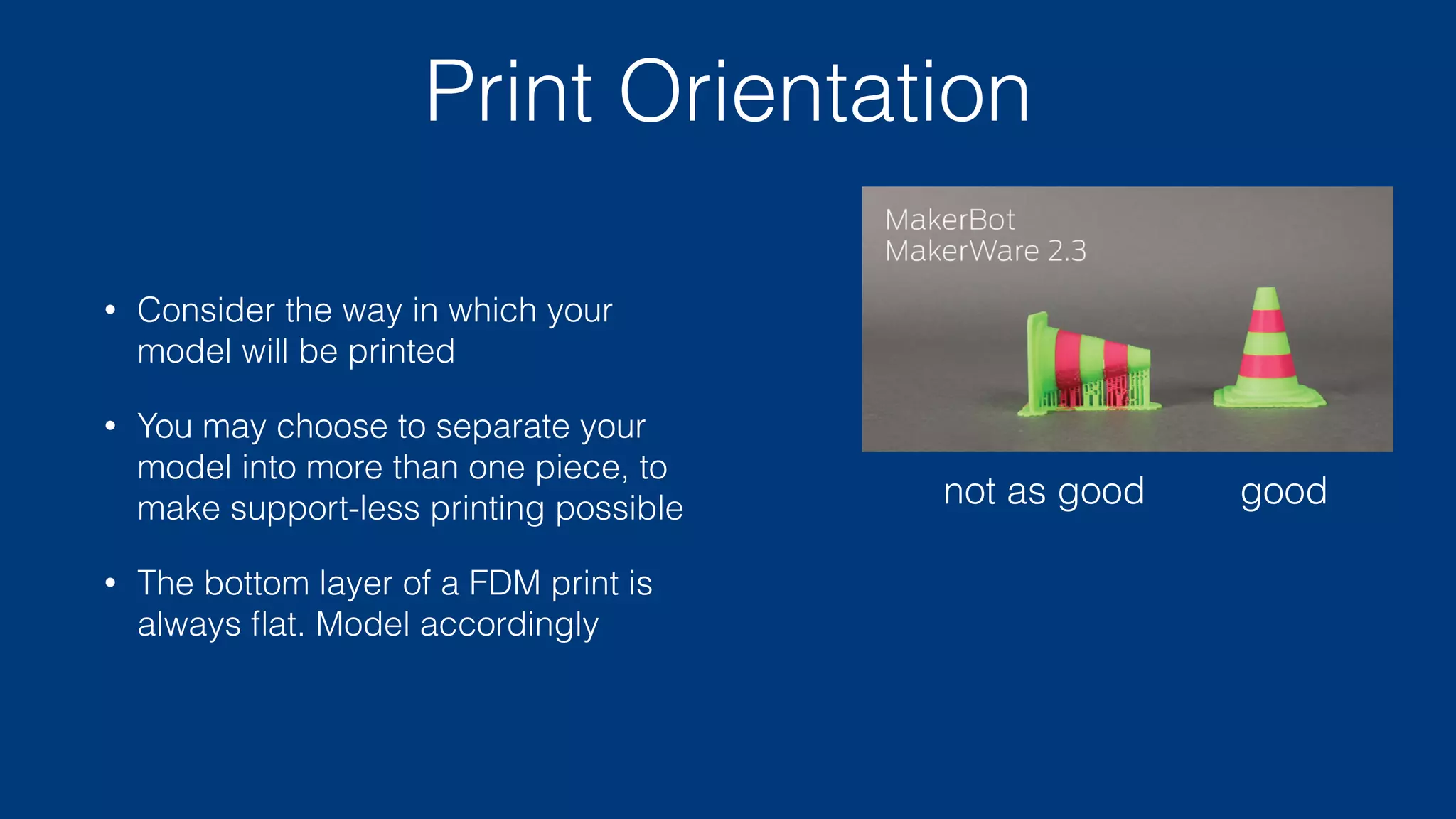

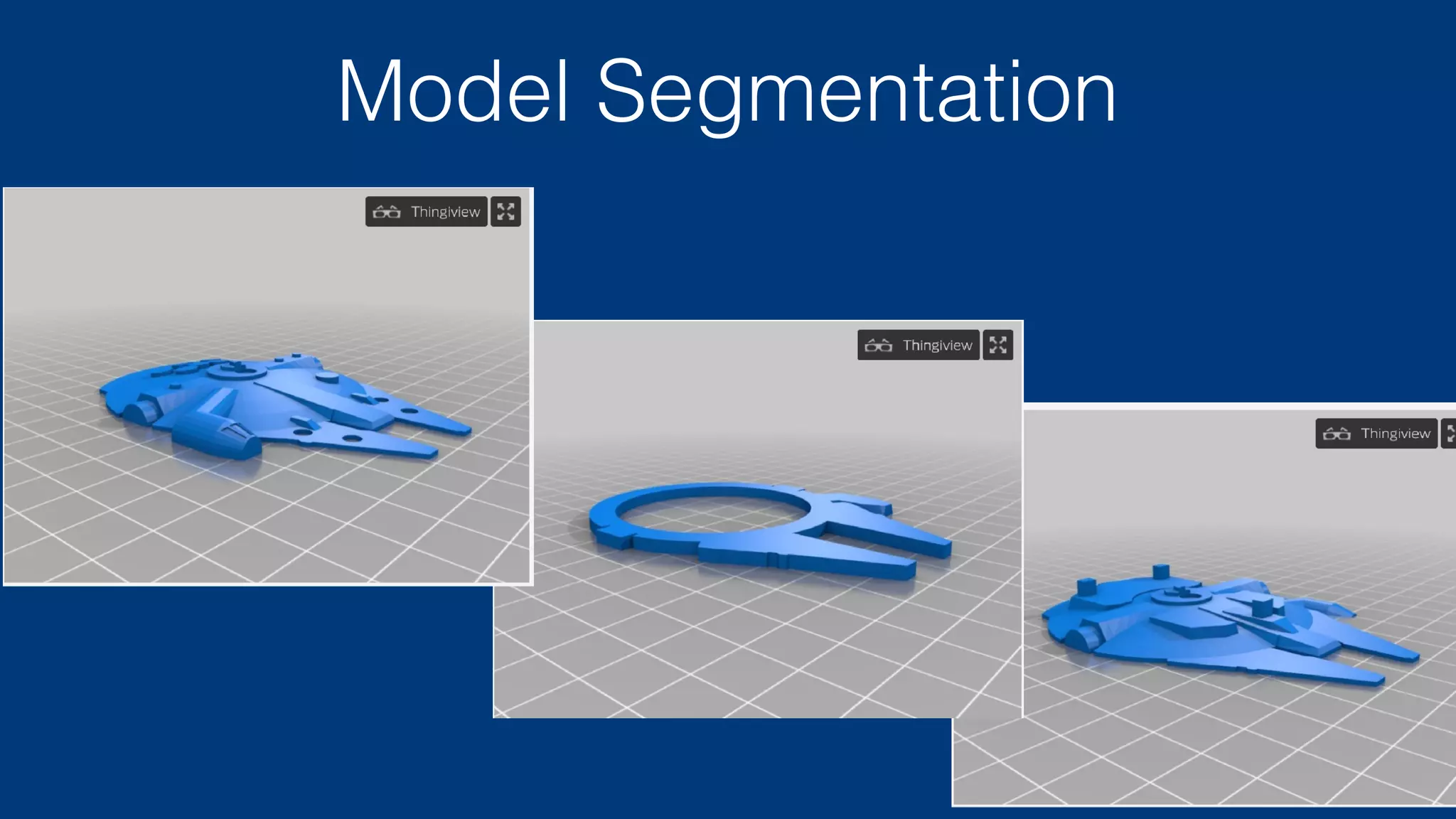

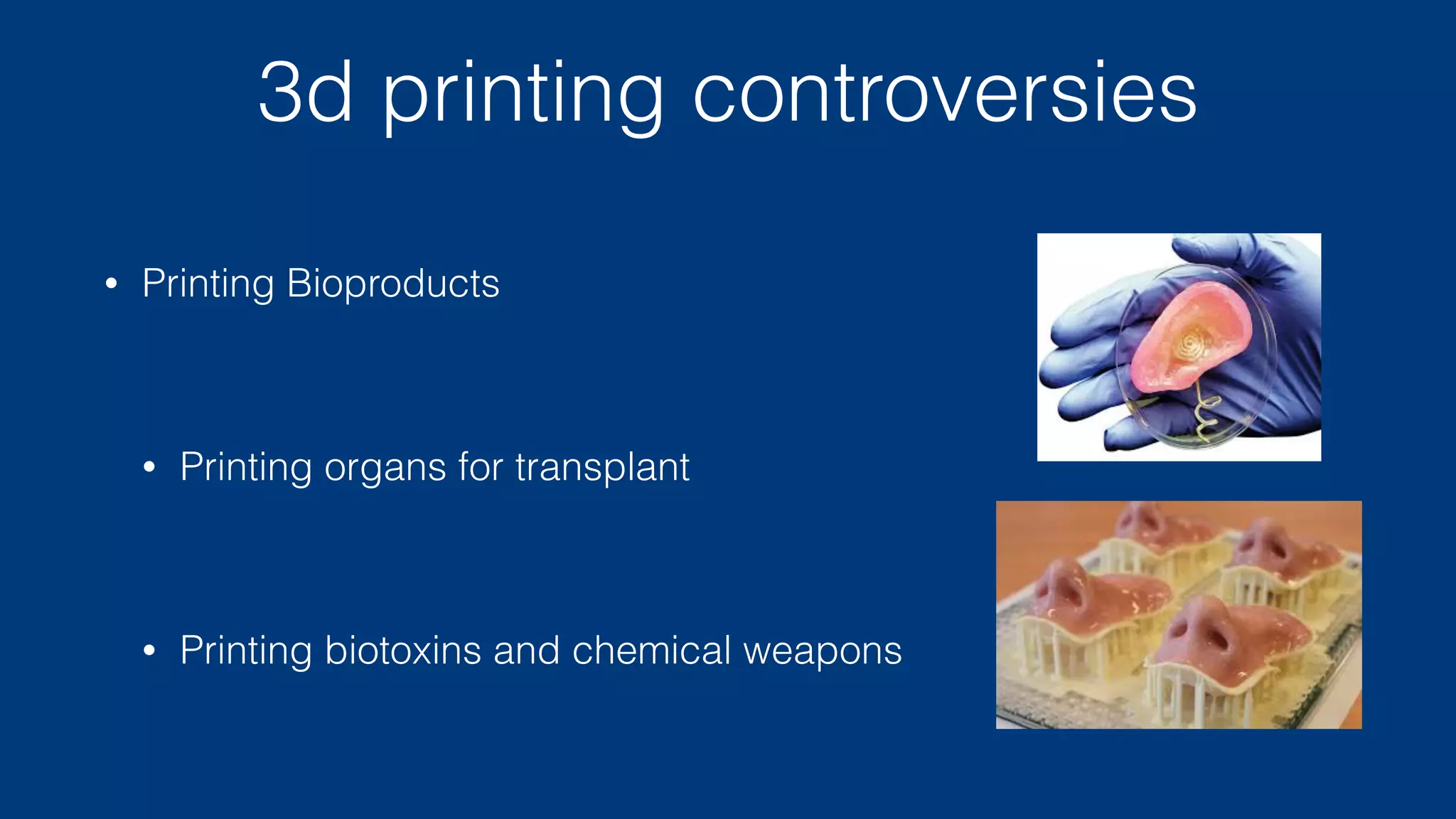

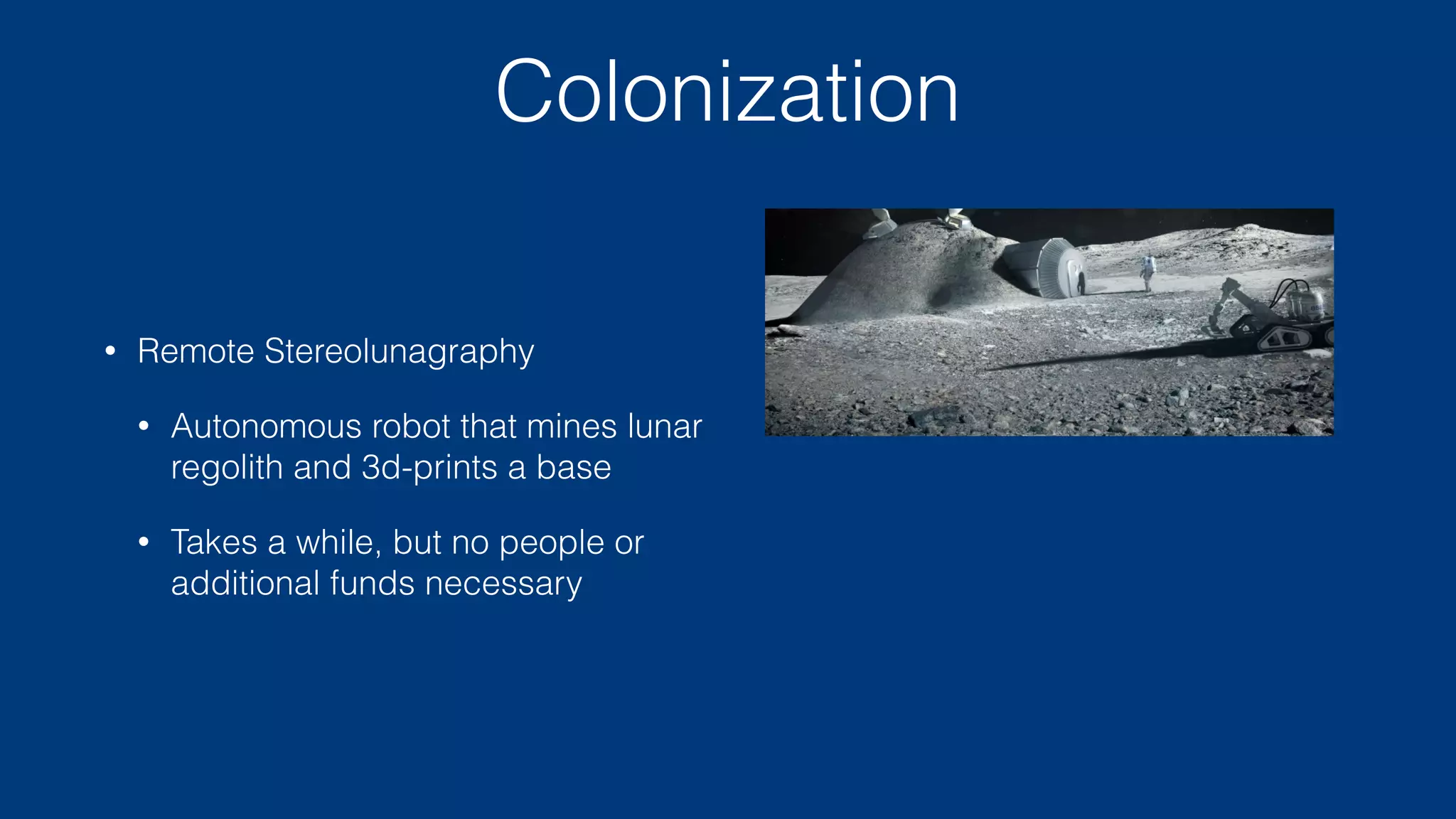

This document provides an overview of 3D printing including its history, key technologies like FDM and SLA, applications, limitations, and future possibilities. It discusses how 3D printing allows for personalization and customization through desktop manufacturing. While early 3D printed parts are not as high quality as traditionally manufactured ones, the document outlines how 3D printing could impact fields like construction, medicine, and space exploration through continued technological improvements.