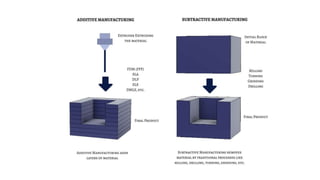

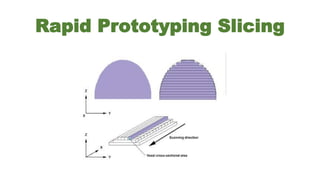

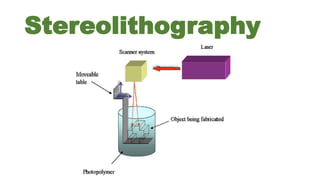

3D printing, also known as additive manufacturing, involves laying down successive layers of material to build a three dimensional object from a digital file. The technology was developed in the 1980s by Charles Hull who created stereo lithography. Since then, other methods like fused deposition modeling and selective laser sintering were introduced. 3D models can be created using CAD software or 3D scanning, and are then converted into an STL file that the 3D printer reads to build the model layer by layer according to the digital design.