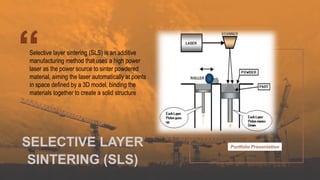

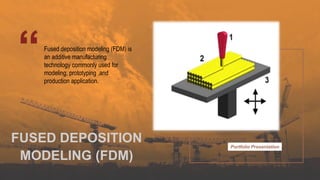

3D printing is an advanced form of printing that builds three-dimensional objects from a digital file. The document outlines the history of printing from wooden block printing to modern techniques like laser printing. It then discusses the evolution of 3D printing from its early concepts in the 1970s to recent advancements. The document explains the 3D printing process and common methods like selective laser sintering and stereolithography. It discusses applications of 3D printing in industries like automotive, medical, and food as well as the role of 3D printing in Industry 4.0. The document also covers the size, cost and impacts of 3D printers as well as advantages, disadvantages, and future scope.

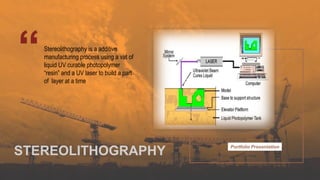

![1984

Chuck Hull of 3D Systems Corporation filed

his own patent for a stereolithography

fabrication system, in which layers are added

by curing photopolymers with ultraviolet light

lasers.

2005

Z corporation launched first

high definition color 3D

printer.

2014

Benjamin S. Cook demonstrate the first multi-

material, vertically integrated printed electronics

additive manufacturing platform which enabled

3D printing of functional electronics operating

up to 40 GHz.

1974

David E. H. Jones laid out the concept of 3D

printing in his regular column Ariadne in the

journal New Scientist.

1993

A company called Solidscape, introducing a

high-precision polymer jet fabrication system

with soluble support structures,

2012

Filabot developed a system for closing the loop[30]

with plastic and allows for any FDM or FFF 3D

printer to be able to print with a wider range of

plastics.

Evolution of 3d printing](https://image.slidesharecdn.com/3dprinting-200415132139/85/3d-printing-6-320.jpg)

![FOOD INDUSTRY

Additive manufacturing of

food is being developed by

squeezing out food, layer by

layer, into three-dimensional

objects.

A large variety of foods are

appropriate candidates, such

as chocolate and candy, and

flat foods such as crackers,

pasta,[28] and pizza.[

NASA has considered the versatility of

the concept, awarding a contract to the

Systems and Materials Research

Consultancy to study the feasibility of

printing food in space.[

One of the problems with food printing

is the nature of the texture of a food.

For example, foods that are not strong

enough to be filed are not appropriate

for 3D printing.

A food-tech startup Novameat from

Barcelona 3D-printed a steak from

peas, rice, seaweed, and some

other ingredients that were laid

down criss-cross, imitating the

intracellular proteins.

NASA is also looking into the

technology in order to create 3D

printed food to limit food waste and to

make food that are designed to fit an

astronaut's dietary needs.[

1

2

3 4

1

5

6](https://image.slidesharecdn.com/3dprinting-200415132139/85/3d-printing-24-320.jpg)