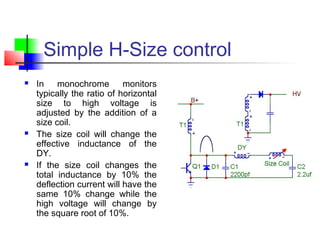

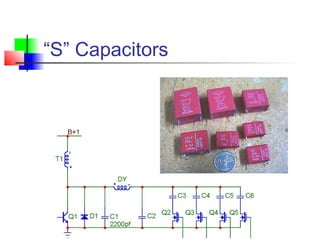

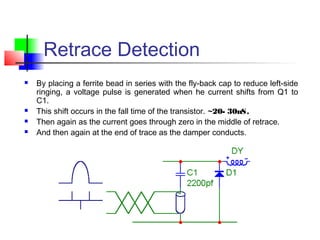

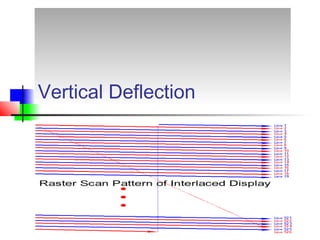

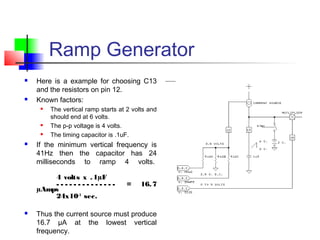

This document discusses the design of CRT displays, including deflection and high voltage systems. It covers scanning methods, deflection principles using magnetic coils, and types of displays like stroke and raster. Vertical and horizontal deflection circuits are described, along with high voltage flyback systems. Details are provided on vertical deflection principles, power amplifiers, retrace boosters, centering, and ramp generators.

![Vertical Linearity

Vertical linearity is achieved by

adjusting the vertical ramp's slope

many times down the screen.

The VSHAPE DAC has an A.C. wave

form on it that modifies the slope of

the ramp to cause linearity

corrections.

At the maximum vertical frequency

and with the [vertical shape at vertical

frequency maximum] set to a value

that causes a 4 volt p-p signal on the

VSHAPE DAC set R12C for good

linearity.

If the vertical frequency is reduced

then the p-p voltage on the VSHAPE

DAC will reduce. This is set by the

[vertical shape at vertical frequency

minimum] control.](https://image.slidesharecdn.com/8f60e942-e3e5-4bc4-842b-f5ff65f05067-160112221136/85/3-_CRT-Display-Design_A_-40-320.jpg)