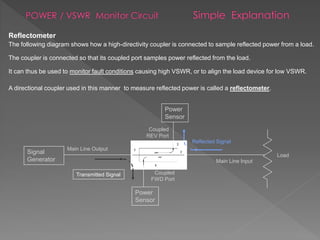

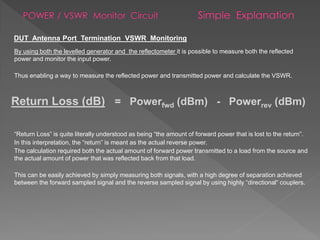

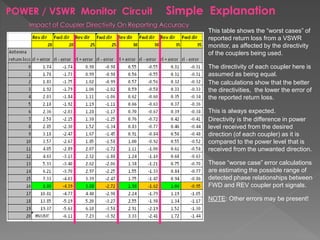

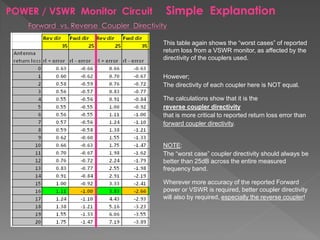

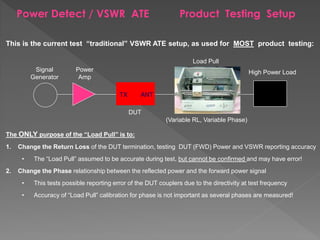

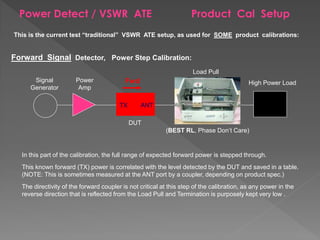

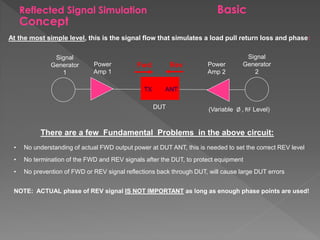

The document provides an overview of power and VSWR monitoring concepts, emphasizing the importance of directional couplers in measuring forward and reflected power. It explains how a reflectometer can be used to monitor fault conditions and aligns load devices for optimal performance. Additionally, it discusses the significance of coupler directivity in accurately reporting return loss and the calibration processes involved in product testing setups.