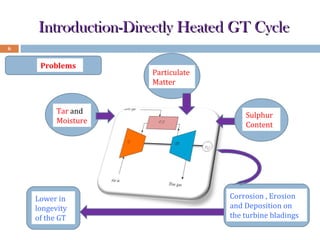

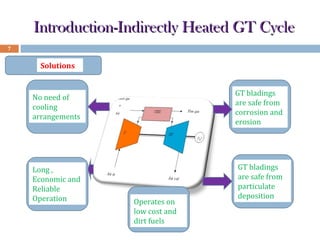

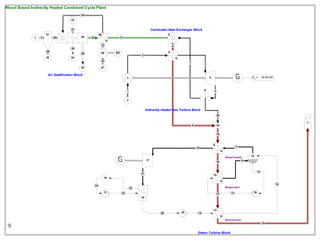

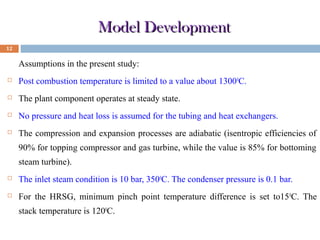

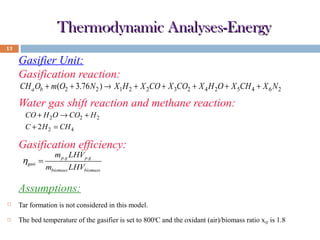

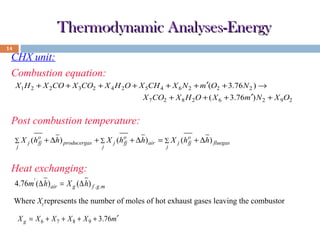

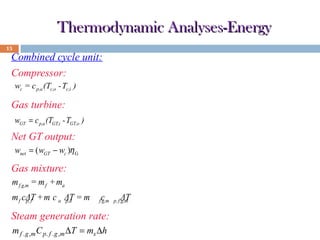

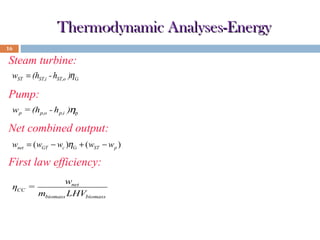

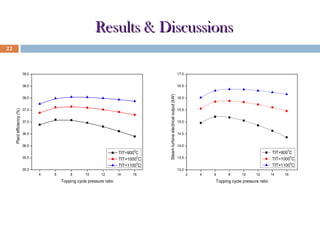

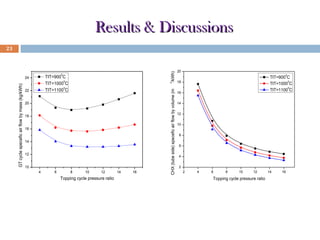

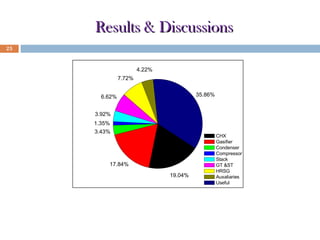

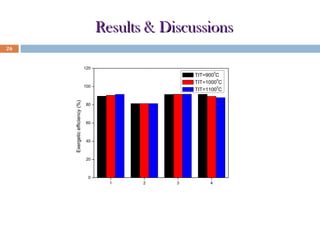

The document summarizes a presentation given at the IV International Conference on Advances in Energy Research. The presentation was given by Pradip Mondal, a PhD scholar at Bengal Engineering and Science University, and discussed the development of a model for a wood-based indirectly heated combined cycle plant. The presentation provided an overview and introduction on biomass and bioenergy resources in India. It then described the schematic layout of the proposed plant and discussed the modeling methodology, including assumptions made. Results showed the plant could achieve over 37% efficiency at optimal operating conditions. The conclusions highlighted that exergy losses primarily occurred in the gasifier, combustor-heat exchanger, gas turbine, and heat recovery steam generator units.