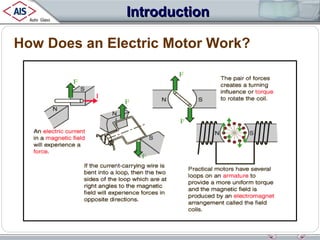

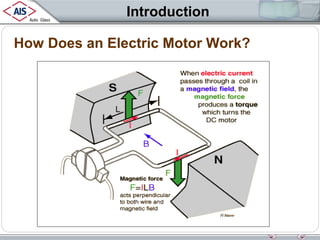

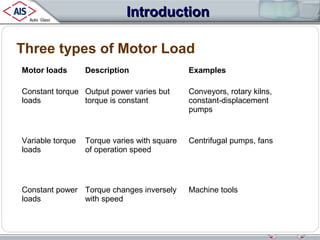

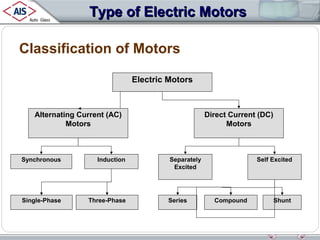

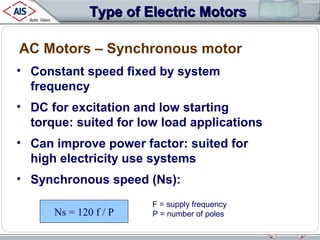

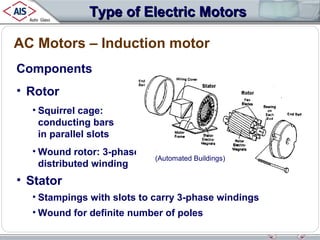

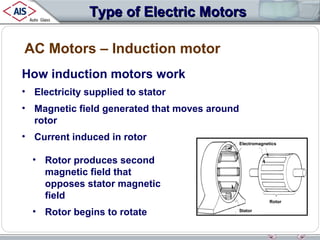

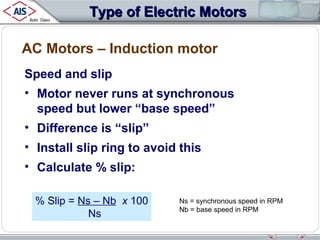

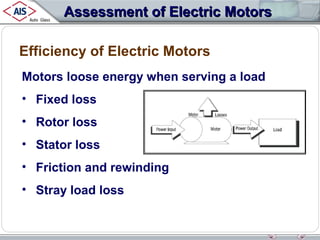

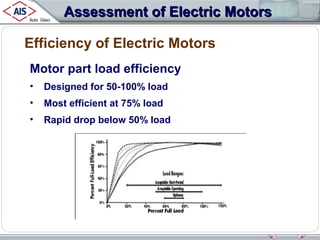

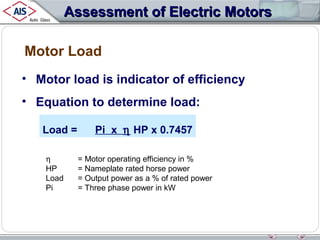

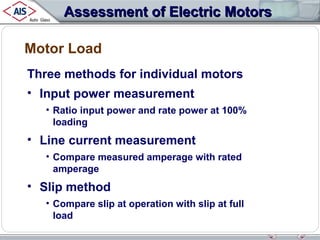

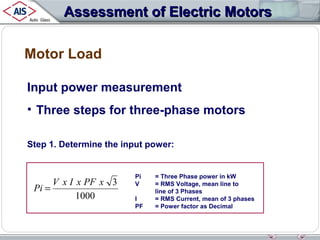

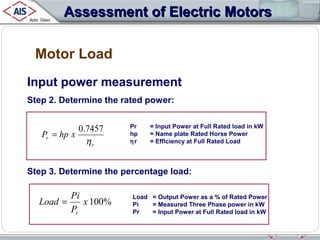

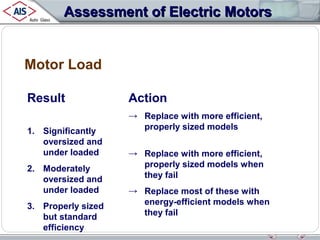

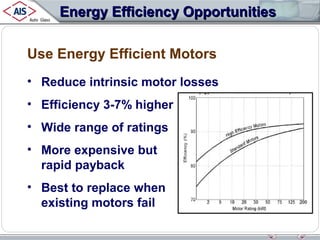

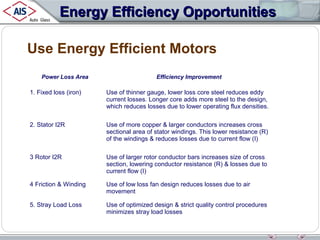

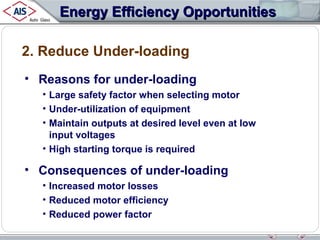

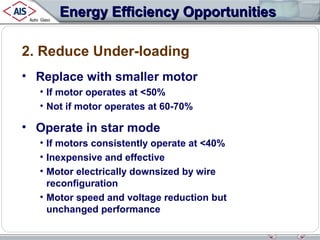

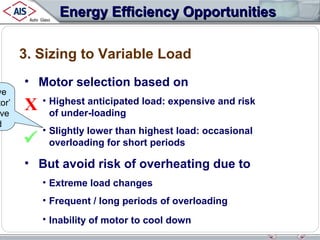

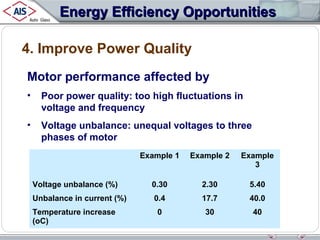

Electric motors are electromechanical devices that convert electrical energy into mechanical energy. The document discusses types of electric motors including direct current (DC) motors and alternating current (AC) motors. It also discusses assessing motor efficiency and energy efficiency opportunities for electric motors such as using energy efficient motors, reducing underloading, improving power quality, and power factor correction.