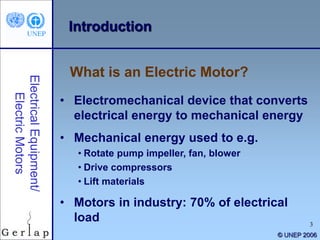

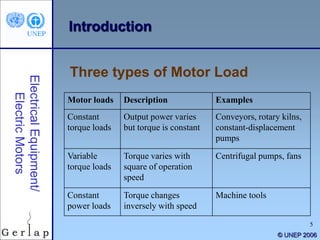

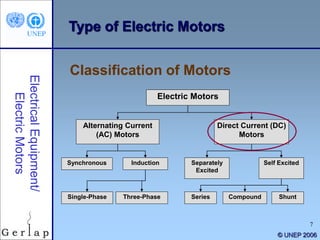

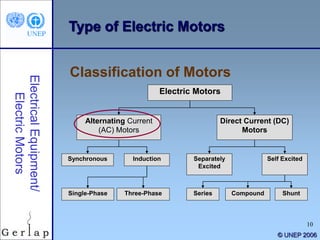

This document provides an overview of electric motors used in industry. It begins with an introduction that defines electric motors and notes they account for 70% of industrial electrical load. It then outlines the training agenda which will cover motor types, assessment, and efficiency opportunities. The document proceeds to describe the different types of electric motors including alternating current motors like induction and synchronous, as well as direct current motors. It provides details on motor components, operation, and classifications. Finally, it discusses factors that influence motor efficiency and how motors lose energy while serving a load.