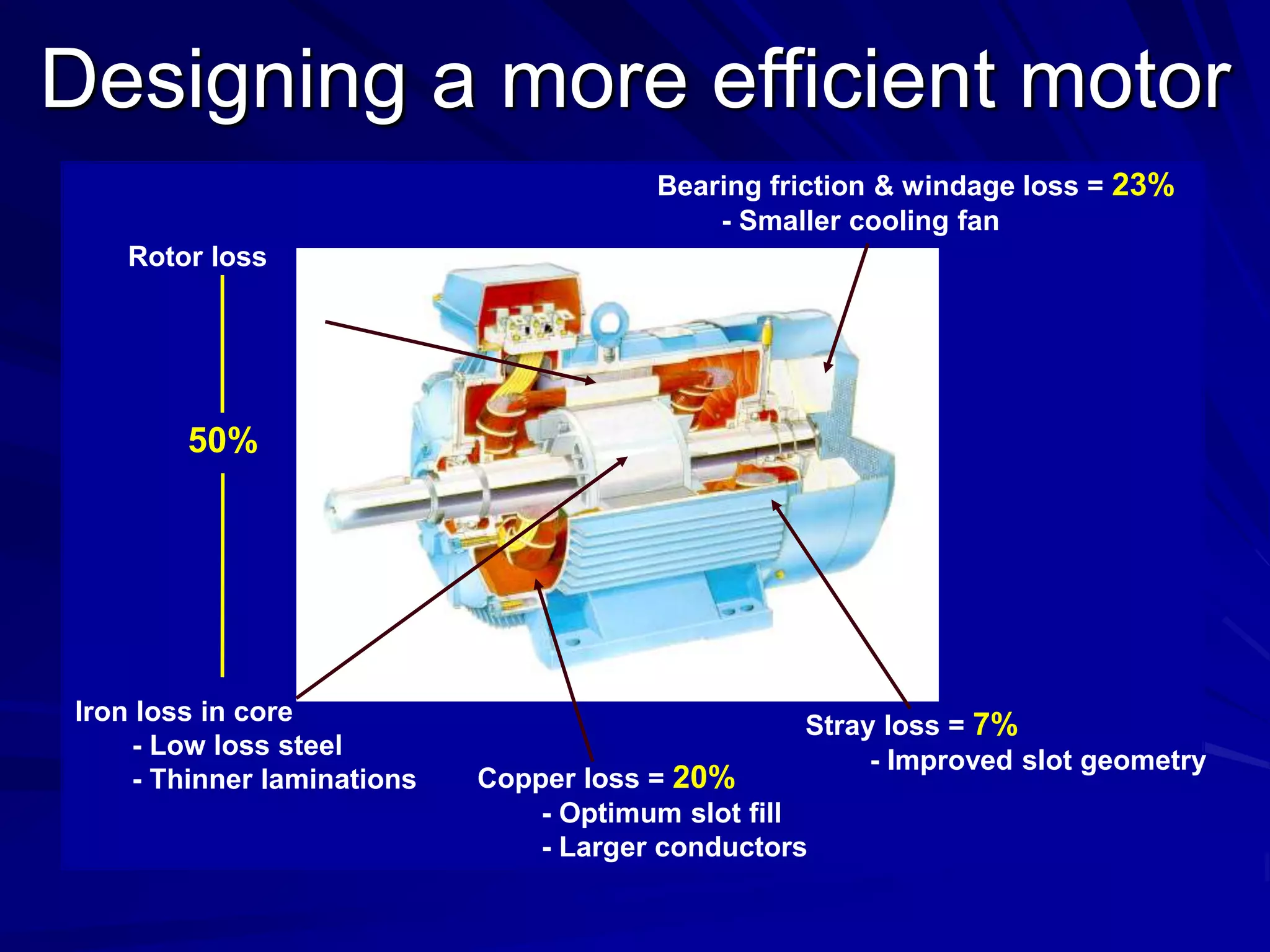

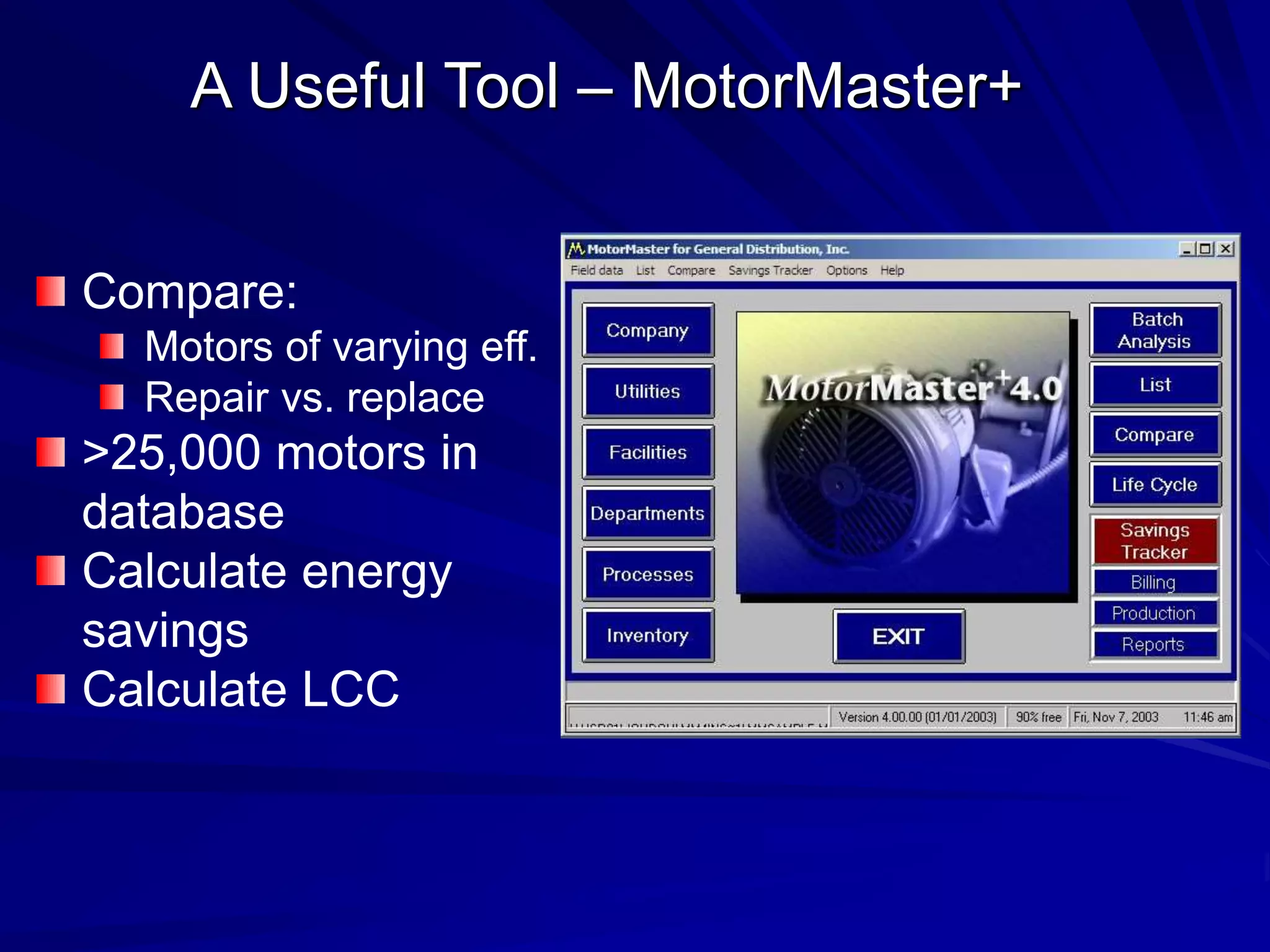

This document summarizes information presented at a white paper on electric motor efficiency. It discusses various types of AC motors, factors that affect motor efficiency like materials and design tolerances, and standards for measuring and testing efficiency. Setting minimum efficiency standards could save 20 billion kWh per year in the US by using premium efficiency motors. Emerging motor technologies like copper rotor motors and electronically commutated permanent magnet motors may further improve efficiency.