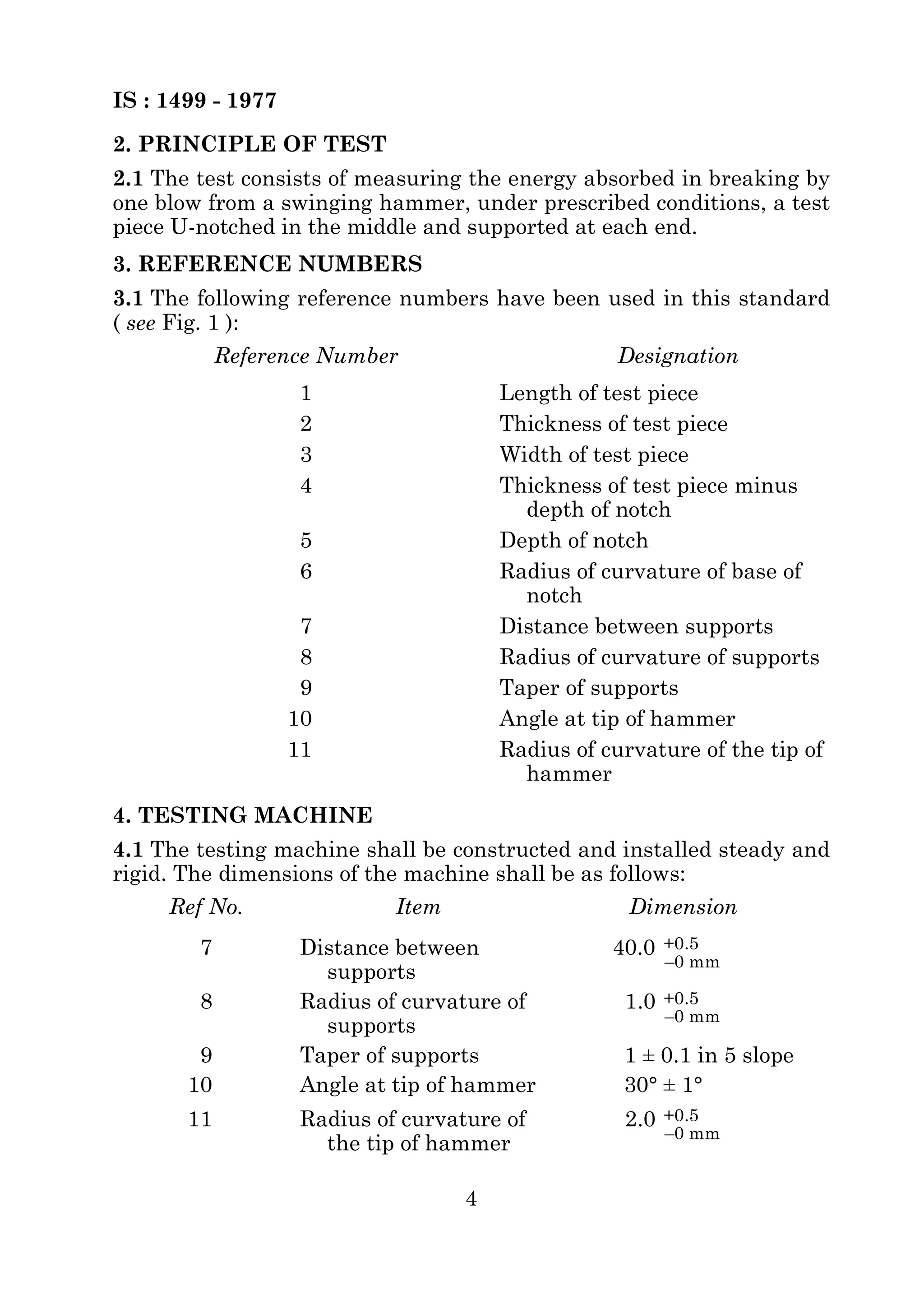

This document describes the Indian Standard method for conducting a Charpy impact test using a U-notch specimen for metals. It specifies the test machine requirements, including hammer speed, dimensions of the supports and hammer. It describes the standard 10x10mm test specimen and two subsidiary sizes, and gives tolerances for specimen dimensions. The procedure covers positioning and temperature of the test, with the standard being at 27°C ±2°C. Three specimens are to be tested and criteria for retests are given. Unbroken specimens are also addressed.