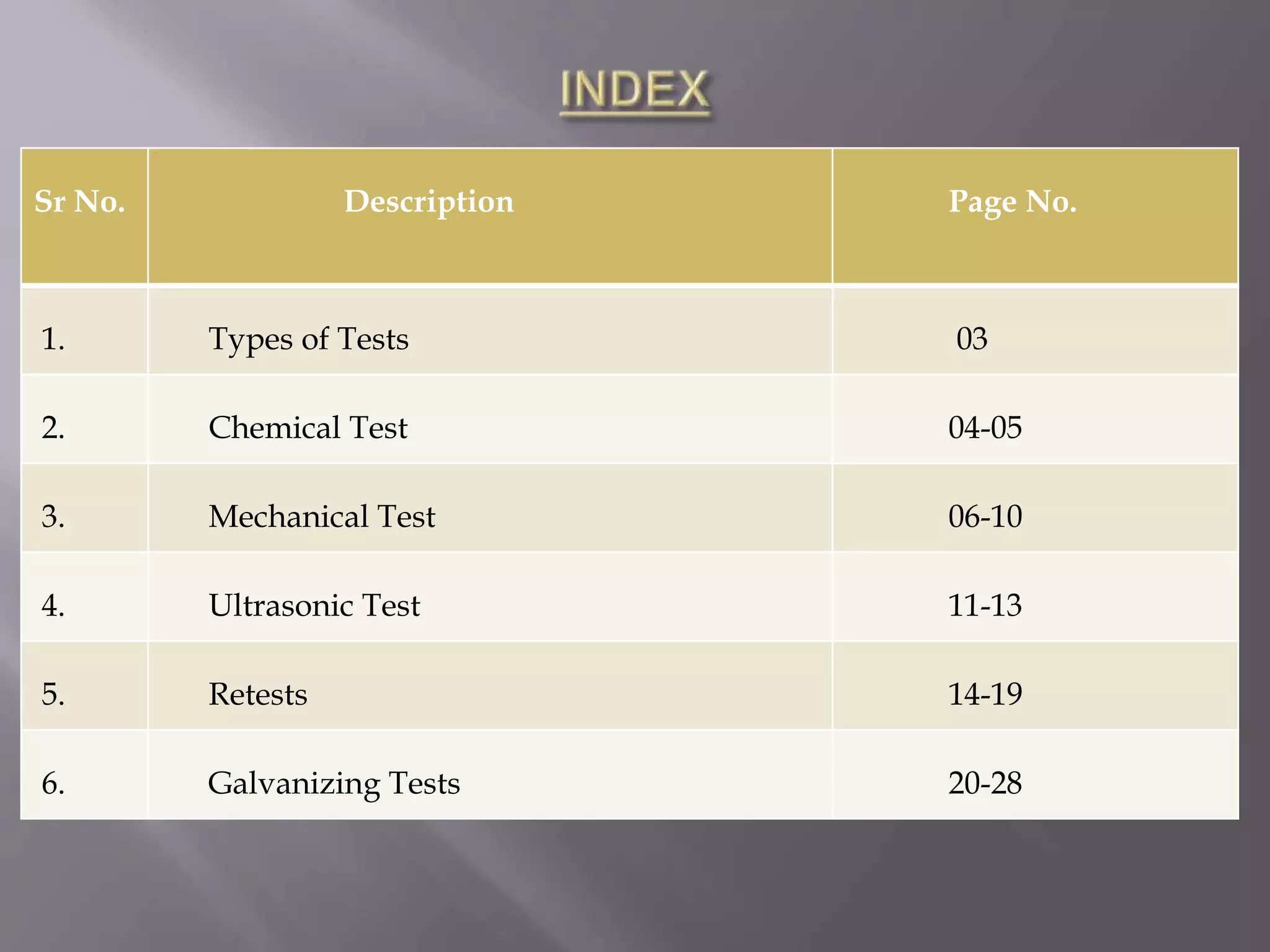

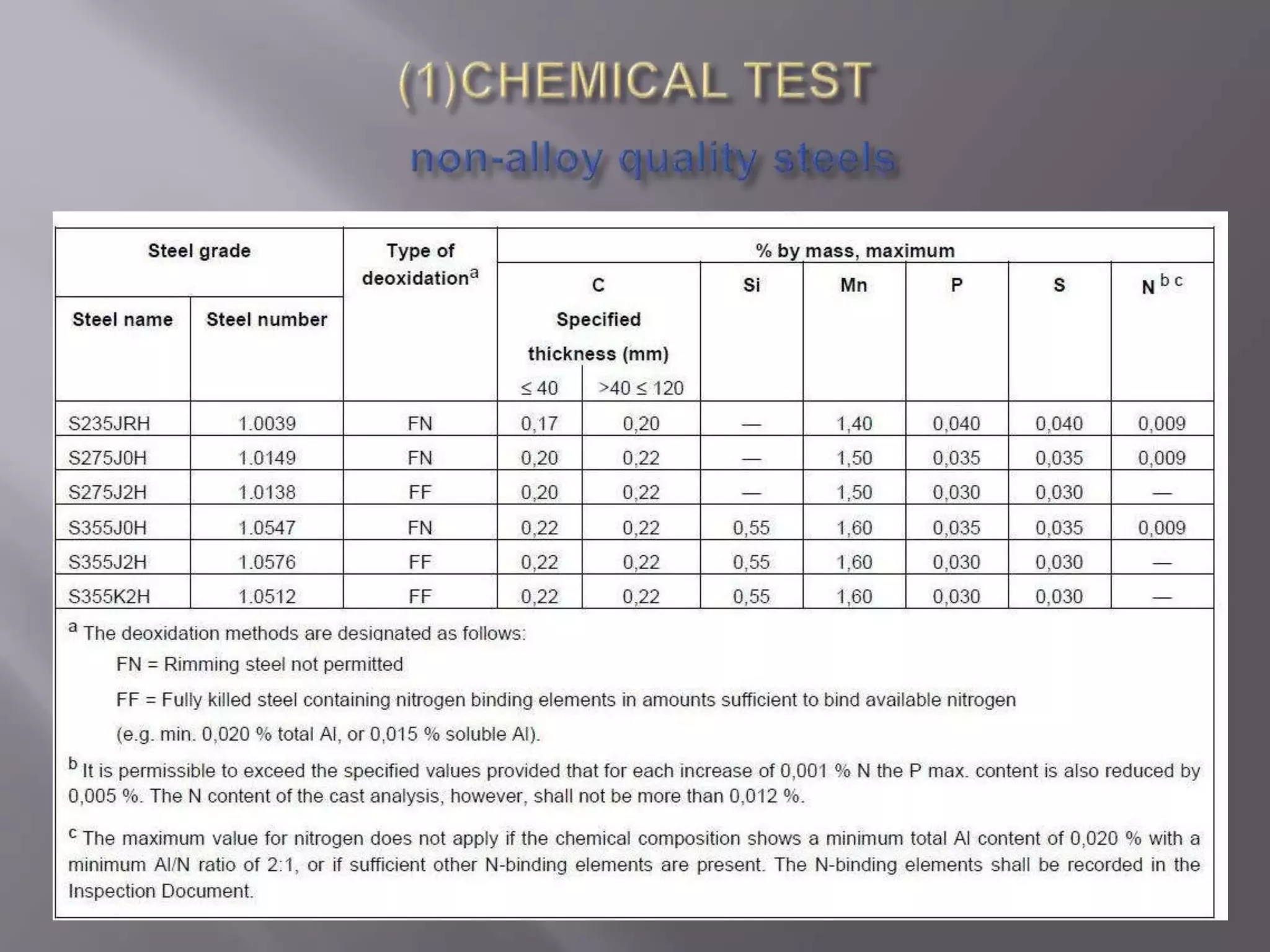

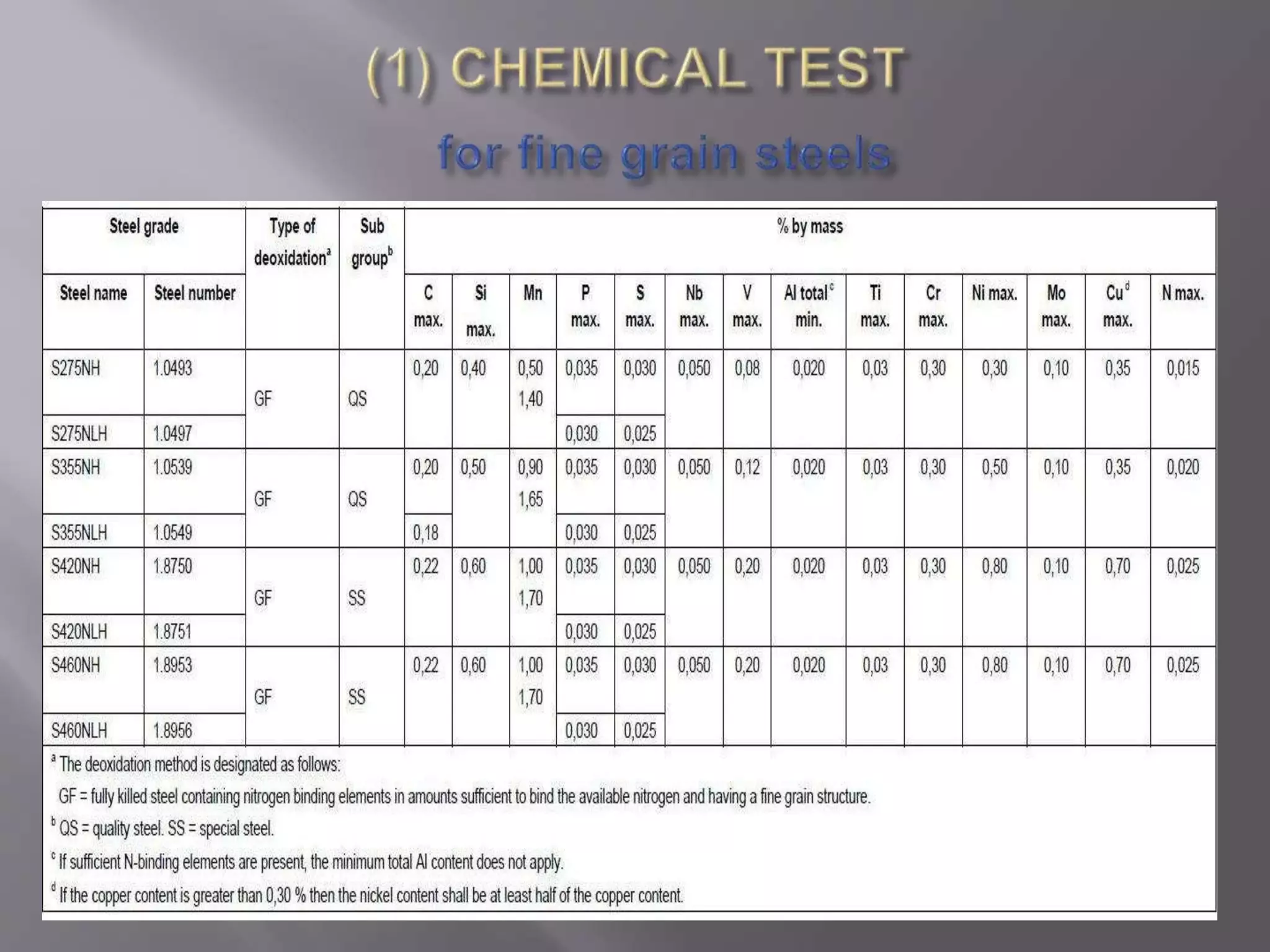

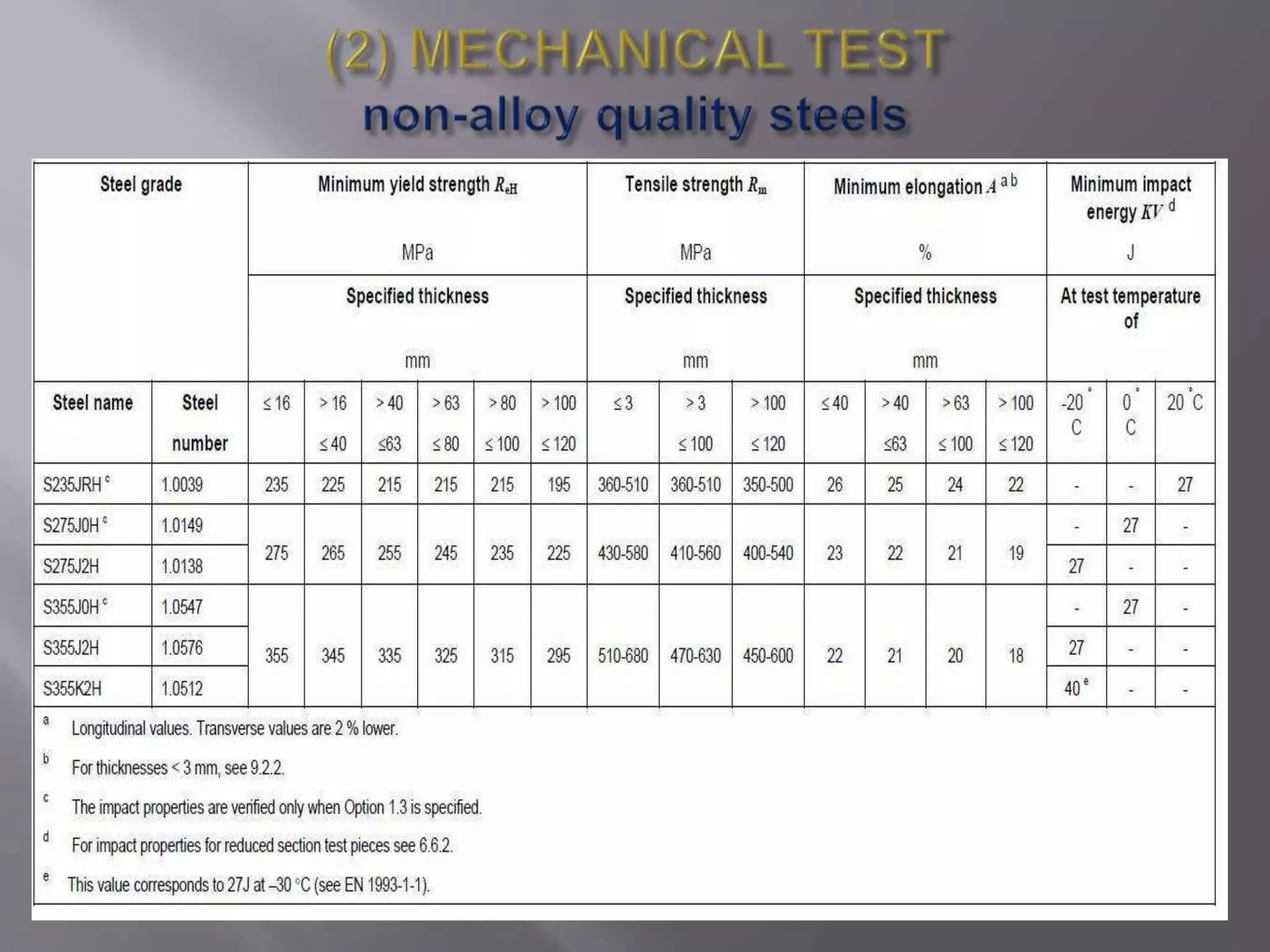

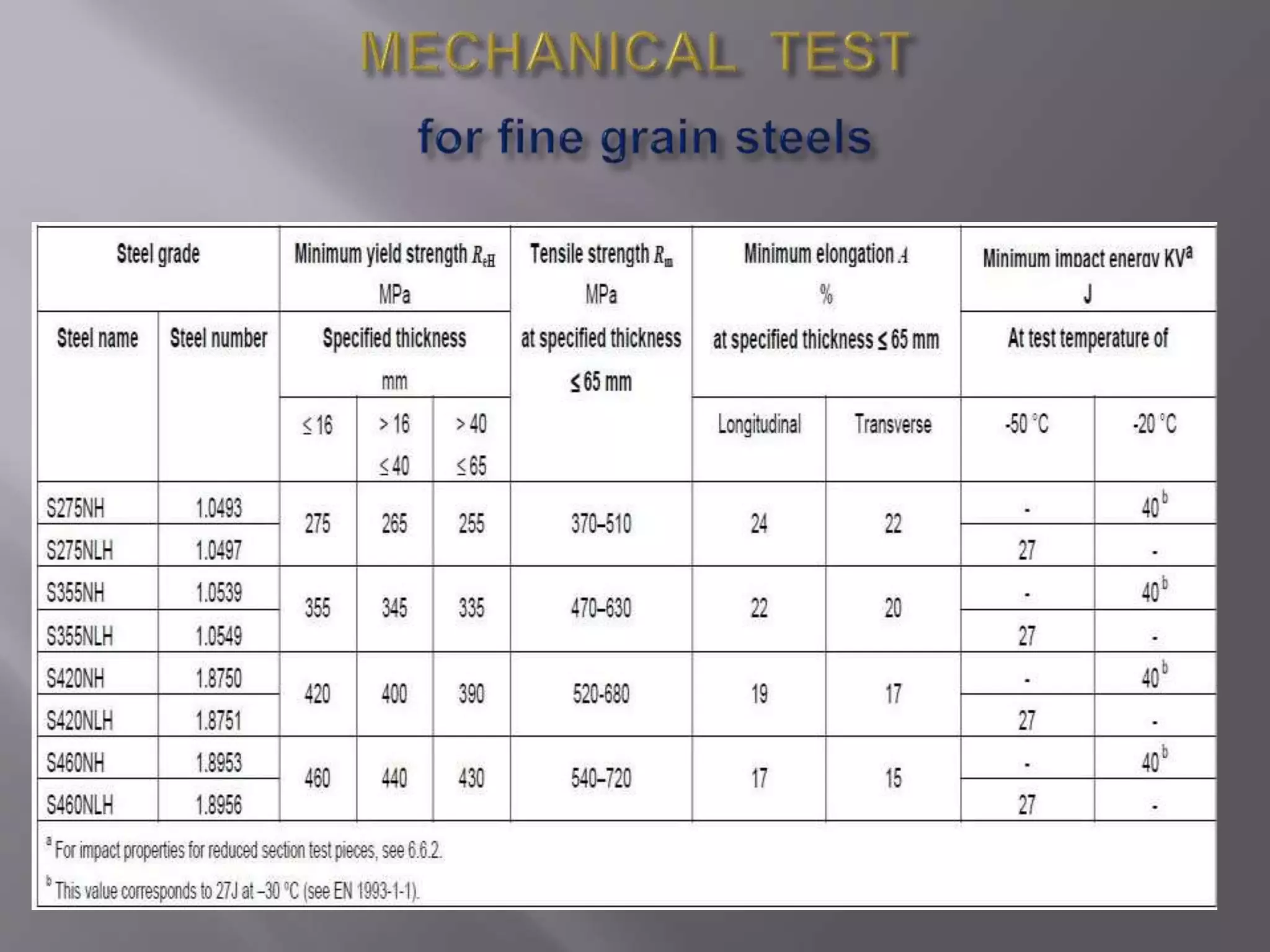

This document outlines various types of tests conducted on materials, including chemical, mechanical, ultrasonic, and galvanization tests. It describes the procedures for tensile, impact, temperature, and ultrasonic tests. Requirements for retests are provided in case of unsatisfactory initial test results. Finally, the document specifies test methods for visual inspection, adhesion, uniformity, and mass of zinc coating for galvanization tests.

![ In case of masts etc. readings shall be taken along the

length at 100 mm interval and in approximate centre of

the flange and then averaged to give a single figure for

thickness of coating.

For castings etc. at least 5 readings may be taken at

convenient locations nearly in the centre.

Thickness, in micro-meters, when multiplied by 7.047

would give the average mass of zinc coating (g/m2).

Three articles in each lot of up to 100 shall be tested in

this manner. Thickness shall not be less than the

minimum.

value specified in Clause 4.1. [i.e 1000 g/m2]](https://image.slidesharecdn.com/masttestingppt-160411111344/75/Mast-testing-ppt-28-2048.jpg)