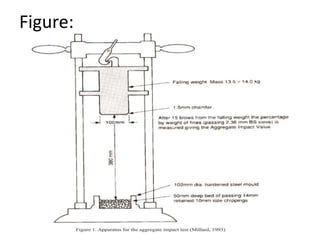

This document describes an aggregate impact testing machine used to evaluate the toughness and resistance to fracture of road stones under repeated impacts. The machine consists of a metal base, cylindrical metal measure, tamping rod, and IS sieves. To test a sample, aggregates are dried, graded, placed in the measure, and compacted. The hammer is then raised and dropped 15 times from 380mm above the sample. The aggregate impact value is calculated as the percentage of material passing a 2.36mm sieve compared to the original dry weight. This test evaluates how well aggregates can withstand the pounding action of traffic loads on roads.