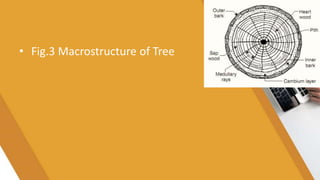

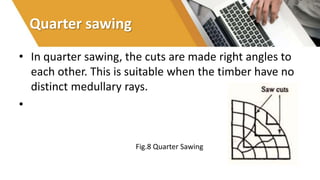

The document discusses the use of wood as a construction material, highlighting its properties and classification into exogenous and endogenous trees. It details the structure of trees, including macro and microstructures, and outlines the processing of timber from felling to preservation. Key steps in timber processing include felling, seasoning, conversion, and preservation to enhance durability and resistance to pests.